Unlocking fired heater performance

Our range of solutions provides optimization for fired heaters, improving radiant efficiency, increasing capacity, and reducing fuel consumption. Cetek and Tube Tech technologies reduce CO2 and NOx, convection section fouling, and bridgewall temperatures.

Complete a Thermal Efficiency Study to determine your projected fuel savings, capacity increase and emissions reduction.

High-Emissivity Ceramic Coatings for Process Tubes and Refractory

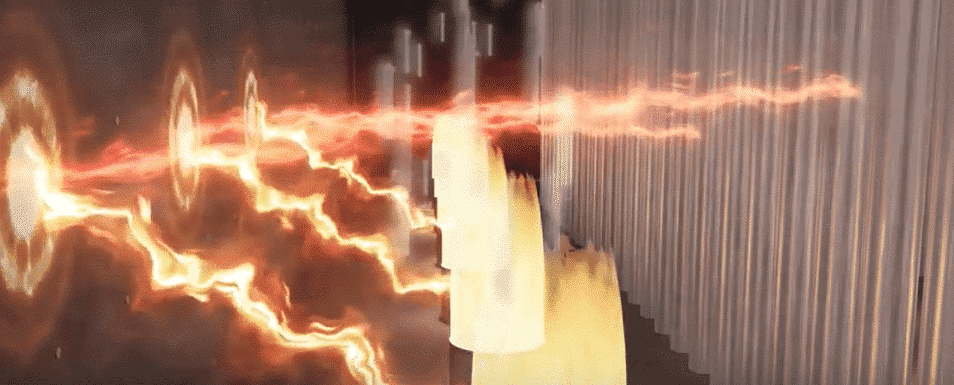

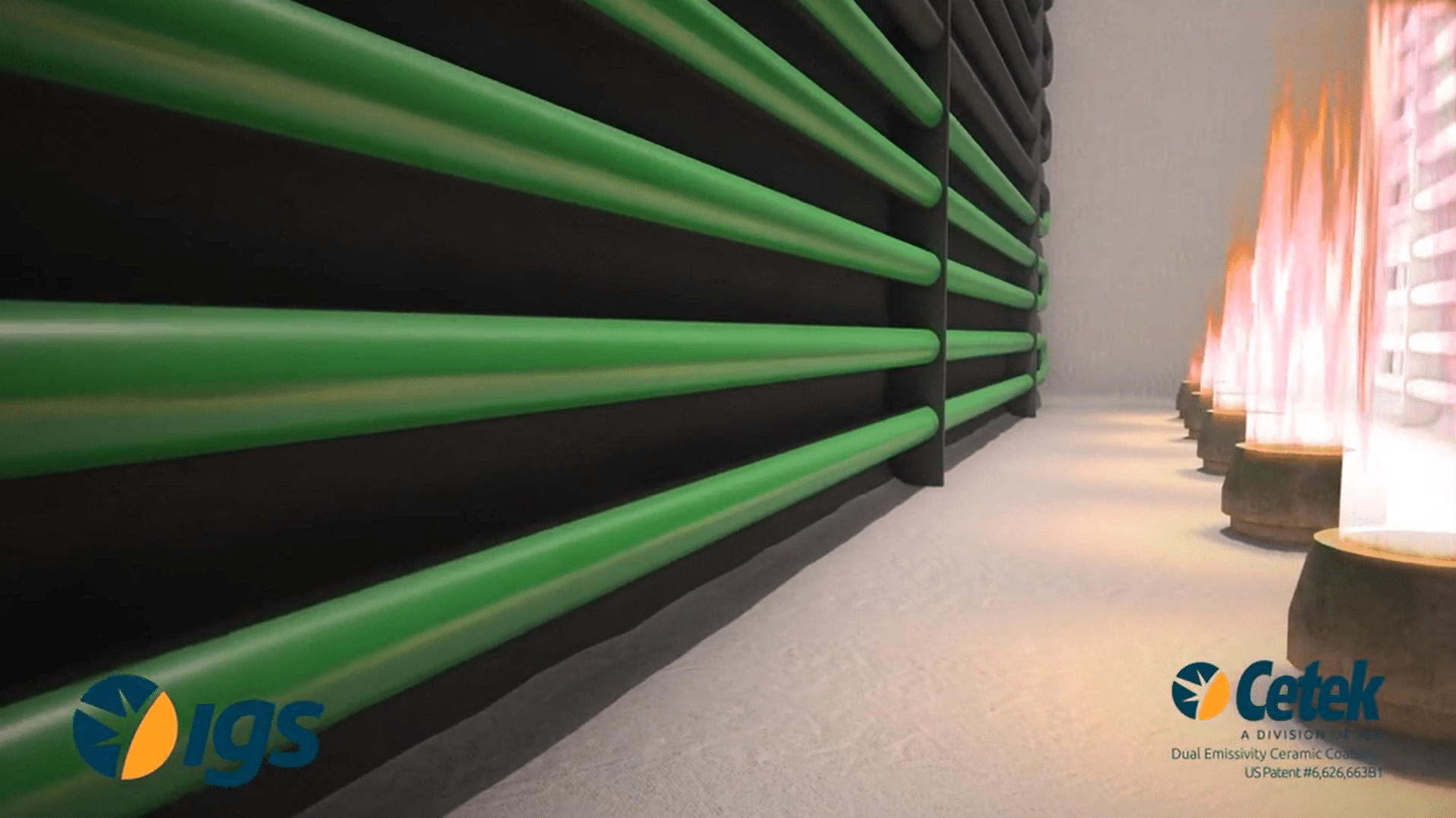

Cetek Ceramic Coatings provide a durable, protective, thin-film layer on the outer surfaces of process tubes, which prevents oxidation, corrosion, and carburization of the metal and maintains the tube thermal conductivity coefficient close to new tube conditions. Tube coating can be applied in conjunction with a refractory coating, increasing the benefit and encapsulating the refractory.

The Benefits

Engineered Convection Section Cleaning

Tube Tech’s fired heater convection section cleaning service is recognised by world-leading refining and petrochemical companies as the most effective technology to achieve OEM performance clean fired heaters.

Traditional cleaning methods are only able to clean 30-45% of the total fouled area. Tube Tech, backed by multi-million-dollar European funding, has developed a Rover system that penetrates deep between tube rows to remove even the most stubborn fouling.

90% clean guarantee even on the most fouled assets.

The Benefits

Online Maintenance & Emergency Services (During the Heater’s Normal Operation)

Hot-tek™ is the industry leader in online maintenance, repair, and cleaning of fired heaters during operation, while the unit continues to produce product. IGS holds multiple patents on the approaches, methods, and tools used to carry out these services. The approach is customized for every client’s needs. Often, multiple Hot-tek™ Services are employed during an application to achieve the best results.

The Benefits