Hot Spot Repair in Live Heaters

Hot spots in the shell of the fired heater limit capacity and can cause a forced shutdown. Our experienced global team mobilizes at short notice to repair refractory online.

What is Refractory Failure?

The refractory may fail prematurely due to the failure of support/anchors holding the lining in place or an operational upset.

In these cases, the operator must decide whether to interrupt production by bringing the heater off-line to make a conventional repair or continue at reduced capacity until the next scheduled shutdown.

Alternatively, an online refractory repair may be made by Hot-tek, where there is no need to bring the heater off-line and production will not be interrupted or limited in capacity.

Hot Spot Repair Procedure Online

IGS has developed a proprietary Hot-tek solution for online hot spot repair. The IGS team creates minimal openings to insert specially designed components and repair material, delivering a semi-permanent repair lasting at least until the next planned turnaround.

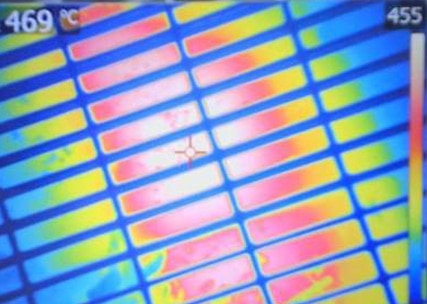

HOT SPOT BEFORE HOT-TEK HOT REFRACTORY REPAIR

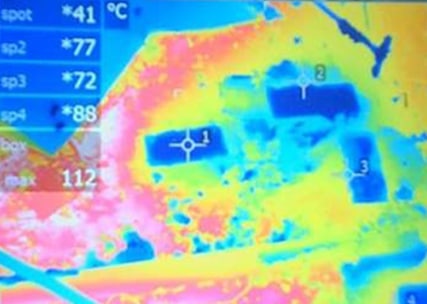

This before and after demonstrates the effectiveness of the IGS Hot-tek Hot Refractory Repair service for fixing hot spots to keep key production assets online.

HOT SPOT AFTER HOT-TEK HOT REFRACTORY REPAIR

IGS Hot-tek online hot spot repair service enabled the client to avoid shutdown, solving the problem while keeping the asset online.

Online Furnace Refractory Repair Using Existing Access Points

Furnace refractory repairs may also be made using existing access points in combination with Hot-tek’s hot inspection service for fired heaters.

If access points are not available, our Hot Access Creation may be used as an integral part of the refractory repair process. In some applications, Hot-tek’s hot inspection service is used to see hard-to-reach areas of the fired heater.

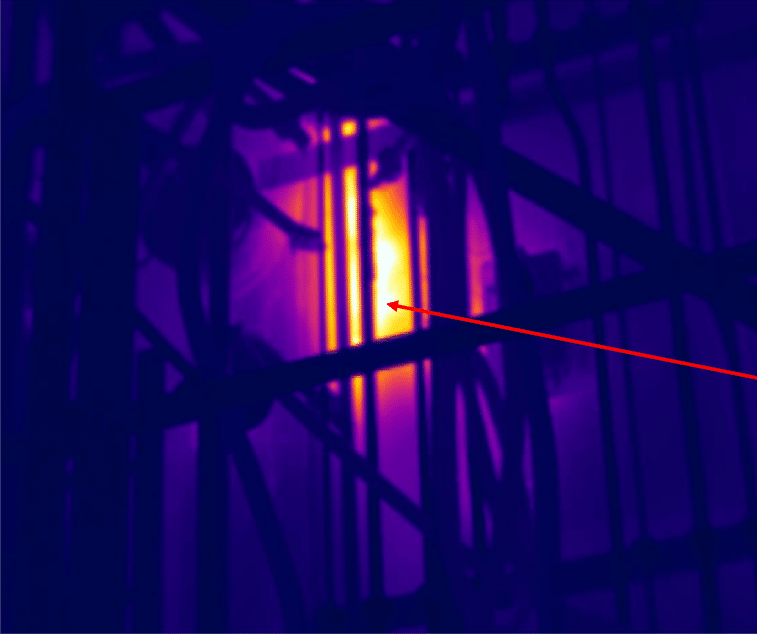

WATCH: Hot Spot Repair Service in Live CCR Heater Prevents $15 Mil Production Loss

Dennis Snijders, IGS Regional Director for the Middle East and North African regions, discusses a memorable project when IGS were called to deal with three severe hot spots in the roof of a Continuous Catalytic Reforming Unit (CCR).

With the next turnaround more than 8 months away and the hot spots surrounding a structural beam, therefore threatening the structural integrity of the CCR unit, taking no action was not an option and finding a solution was urgent for this customer.

IGS Hot-tek online hot spot repair service enabled the client to solve the problem while keeping the asset online, saving weeks in lost production – an estimated $15M.

IGS mobilized quickly, fixing the initial three hot spots within just two days. However, in that time, the client had assessed that further hot spots had developed on the roof of the CCR unit – 39 in total! The IGS Hot-tek team repaired all 39 hot spots, staying onsite for one month in total to ensure the project was executed to the highest quality and safety standards.

What is the purpose of refractory?

All process heaters operate at high temperatures and are constructed with process tubes inside a refractory-lined enclosure, which is heated by radiant heat from firing of natural gas or, less commonly, oil-firing.

Refractory linings are insulating and minimize heat loss, making them essential to retaining the high-temperature environment.

What are three different types of refractories?

There are three types of refractory lining:

- Refractory ceramic fiber

- Brick

- Castable/concrete

What is refractory installation?

Refractory linings are installed when the process heater is originally fabricated. Refractory is repaired or replaced during turnarounds when all, or part of the lining has reached its end of life.