Hot Tube Stabilization

Stabilizing Fired Heater Dislodged Tubes

Maintaining the integrity and efficiency of fired heaters is crucial in the demanding environment of refinery operations. Fired heaters are essential components in the refining process, and their performance directly impacts the overall productivity and safety of the refinery. One of the critical aspects of fired heater maintenance is the stabilization of heater tubes.

There are multiple issues faced by refinery engineers, such as coke build-up inside tubes, tube bowing, heater tube support dislodging, and broken tube hangers, and IGS provides comprehensive solutions for fired heater tube stabilization.

Understanding Fired Heater Tube Stabilization

Fired heater tube stabilization is a process aimed at ensuring the structural integrity and optimal performance of heater tubes. Over time, heater tubes can experience various issues that compromise their functionality. Addressing these problems promptly is essential to prevent costly downtime and ensure the safe operation of the refinery.

Common Issues and Root Causes

- Coke Buildup Inside Tubes

Coke buildup inside heater tubes is a common problem that can significantly reduce heat transfer efficiency and increase the risk of tube failure. Coke is a carbonaceous material that forms as a byproduct of the thermal cracking process. It adheres to the inner walls of the tubes, creating an insulating layer that impedes heat transfer, leading to non-uniform overheating of the tube metal.

- Tube Bowing in Fired Heaters

Tube bowing occurs when heater tubes deform due to uneven heat flux, thermal expansion and mechanical stress. This deformation can lead to reduced integrity and potential tube rupture

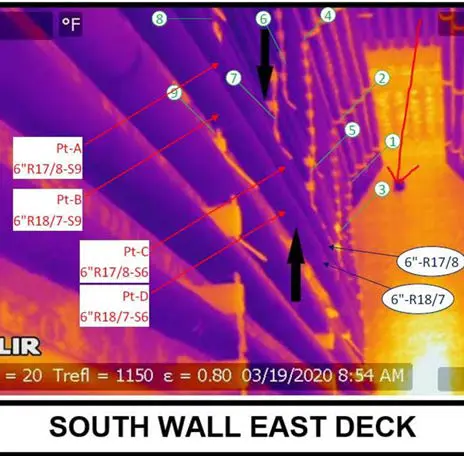

- Heater Tube Support Dislodging

Heater tube supports play a crucial role in maintaining the alignment and stability of the tubes. When these supports become compromised , the tubes can sag or shift, leading to mechanical damage and reduced heat transfer efficiency.

- Broken Tube Hanger

Tube hangers are designed to support the weight of the heater tubes and maintain their alignment. When tube hangers break, the tubes can sag or collapse, causing significant operational disruptions. The primary reasons for broken tube hangers are:

-

- Material fatigue and wear

- Corrosion and environmental factors

- Improper installation and maintenance

On-line Solutions for Effective Fired Heater Tube Stabilization

IGS has developed a Hot-tek™ online repair process to stabilize the process tubes while the heater is still in full operation. The service can prevent costly shutdown and let the operator run the unit until the planned turnaround dates.

Stabilizing the Process Tube

The stabilizer can either be supplied by the customer or fabricated by IGS.

Application Procedure

Utilizing proprietary procedures, IGS technicians will:

- Asses risks and develop a risk mitigation plan

- Make a penetration in the vicinity of the failed tube support

- Insert the stabilizer

- Weld the stabilizer in place

- Replace the refractory

- Replace the external steel shell in the repair area

- Control quality

It is important to note that the process tube will be secured in its present position. It will not be returned to its original location. The necessary process tube inspection and hanger replacement should be completed at the next turnaround.

Safety is the most important factor in performing this type of repair. IGS technicians have performed hundreds of such Hot-tek™ online services with no accidents/incidents.

Fired Heater Maintenance and Repair with IGS

Fired heater tube stabilization is a critical aspect of refinery operations that directly impacts efficiency, safety, and productivity. By understanding the common issues and root causes, such as coke buildup inside tubes, tube bowing, heater tube support dislodging, and broken tube hangers, refinery engineers can implement effective solutions to maintain the integrity and performance of fired heaters. Regular inspection and maintenance will ensure the long-term reliability and efficiency of fired heaters, contributing to the overall success of refinery operations. IGS can provide a Hot-tek™ on-line repair in any place in the world.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.