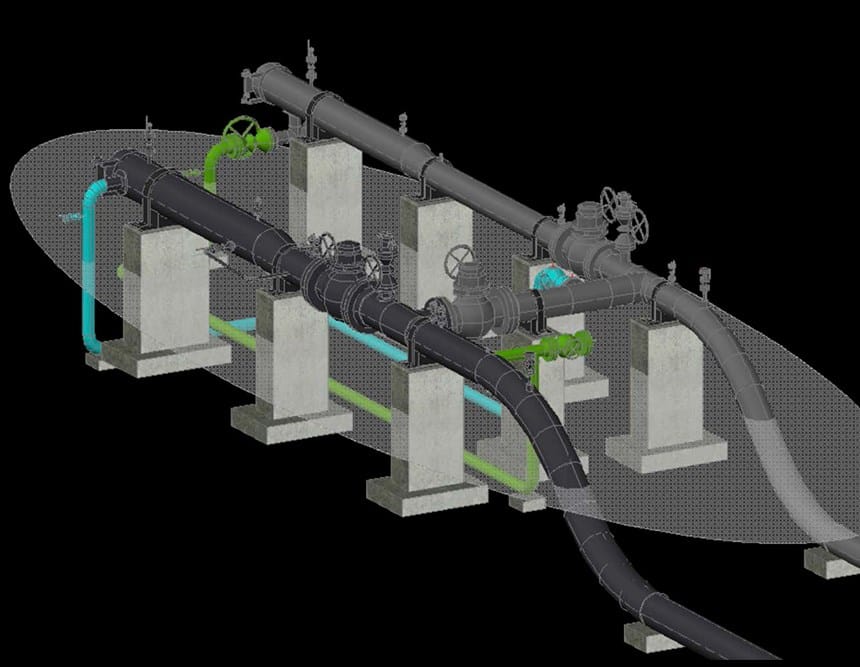

Transporting untreated wet gas poses significant corrosion risks, particularly from H2S and CO2, to the wet gas pipelines. Understanding and mitigating this corrosion is imperative for maintaining pipeline integrity and operational efficiency.

In the fight against wet gas corrosion, the Metalspray PipeID Rover presents a groundbreaking solution, offering a no-man-entry, field-applied alloy upgrade for wet gas pipelines, finger slug catchers, and flare lines. This innovative technology has emerged as a critical tool in corrosion mitigation, enabling effective protection and extending the lifespan of essential offshore infrastructure

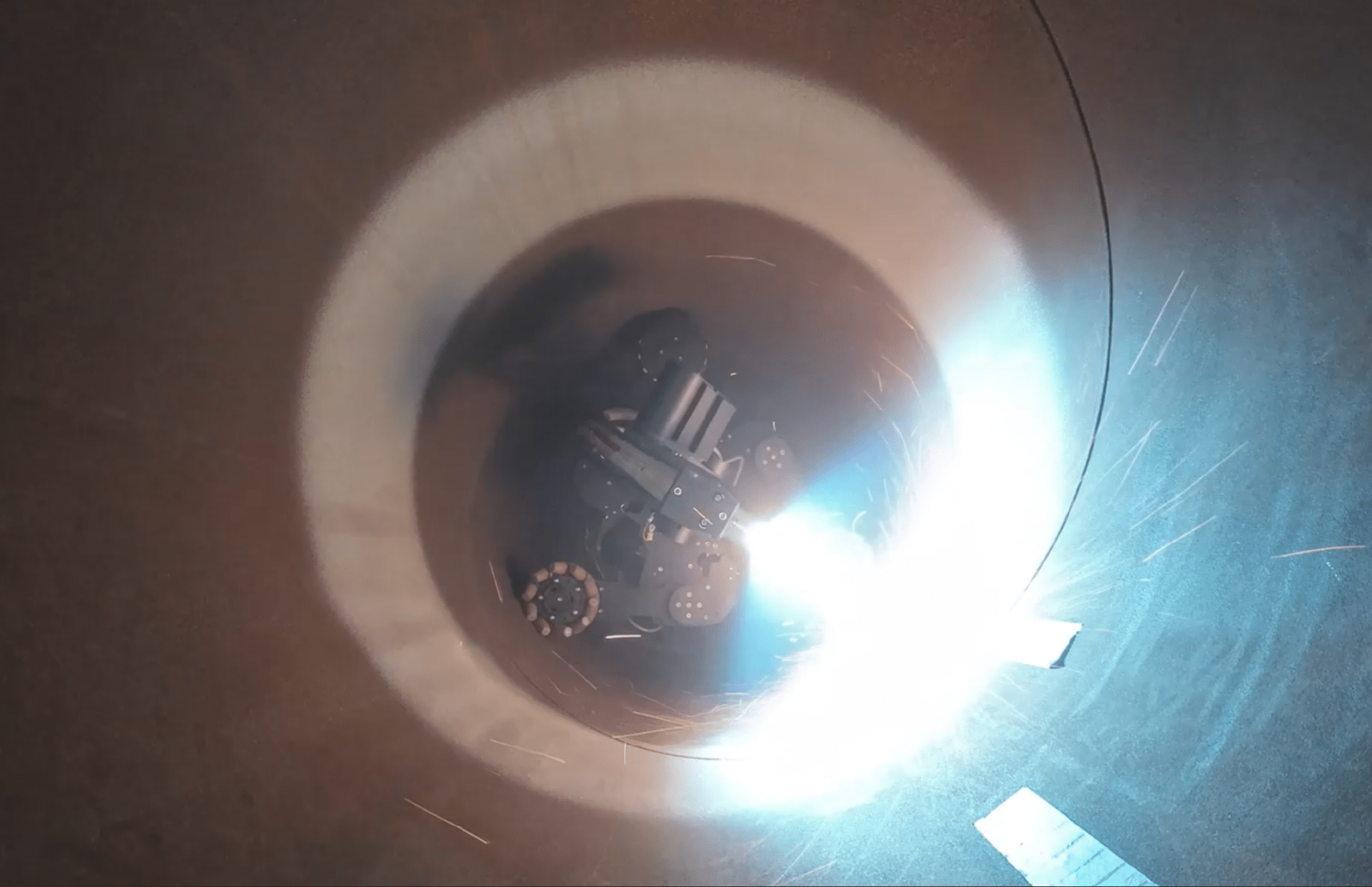

The Metalspray PipeID Rover system represents a leap forward in corrosion control technology. Designed for direct application within pipelines and slug catchers, it facilitates surface preparation, alloy upgrade, quality control, and debris removal—all without the need for human entry. This self-propelled rover performs targeted Metalspray alloy upgrades on areas most susceptible to corrosion, employing unique non-contact preparation tools that remove corrosion products and inspect surfaces for comprehensive metallurgical bonding and corrosion protection. Equipped with lidar and camera, the rover conducts integrity scans to ensure thorough coverage and effectiveness.

Offers 360-degree access to critical areas such as bottom sections, low spots, seams, and welds, ensuring comprehensive coverage and protection.

On-site alloy upgrade stops corrosion and protects the affected areas against future corrosion, significantly extending asset life.

Provides essential documentation and visual confirmation of the condition before and after the application, ensuring quality and accountability.

Designed to operate safely inside the pipe, eliminating the need for confined space entry and reducing safety risks.

By maximizing capital efficiency and avoiding the need for expensive replacements of wet gas pipes, the Rover offers a financially viable solution to corrosion challenges.

With its ability to halt further damage and reinforce pipeline infrastructure, the Metalspray PipeID Rover is not just a tool but a comprehensive strategy against wet gas corrosion. It supports operators in strengthening their offshore infrastructure, ensuring uninterrupted production, and protecting their investment in pipeline systems. By enabling in-service repairs, the Rover plays a pivotal role in avoiding slug catcher replacements and the associated production interruptions, marking a significant advancement in corrosion engineering solutions.