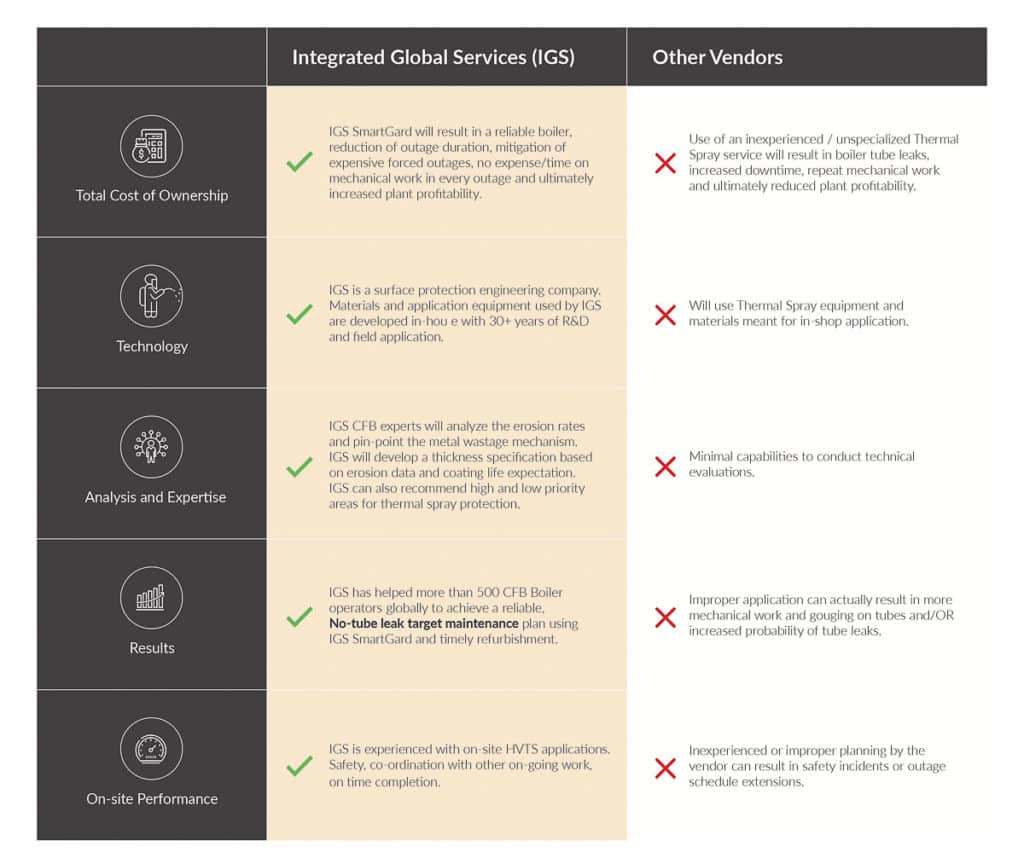

IGS leverages decades of experience with over 500 boiler reliability applications. We are at the forefront of maximizing run time while minimizing outage frequency and cost.

IGS solution has been successfully implemented to provide scalable, proactively manageable and fully refurbishable boiler tube protection from fly ash erosion and fireside corrosion.

Solution characteristics, alloy features, technological benefits, erosion resistance, and much more.

We understand the wear patterns and problem areas in the boiler by investigating the following:

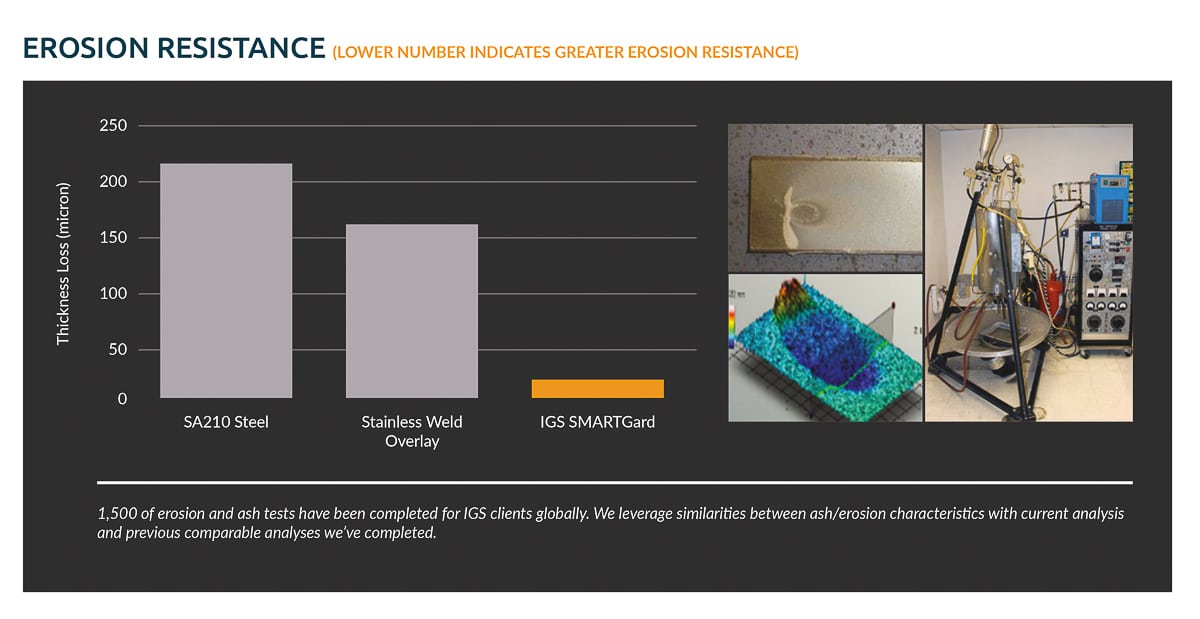

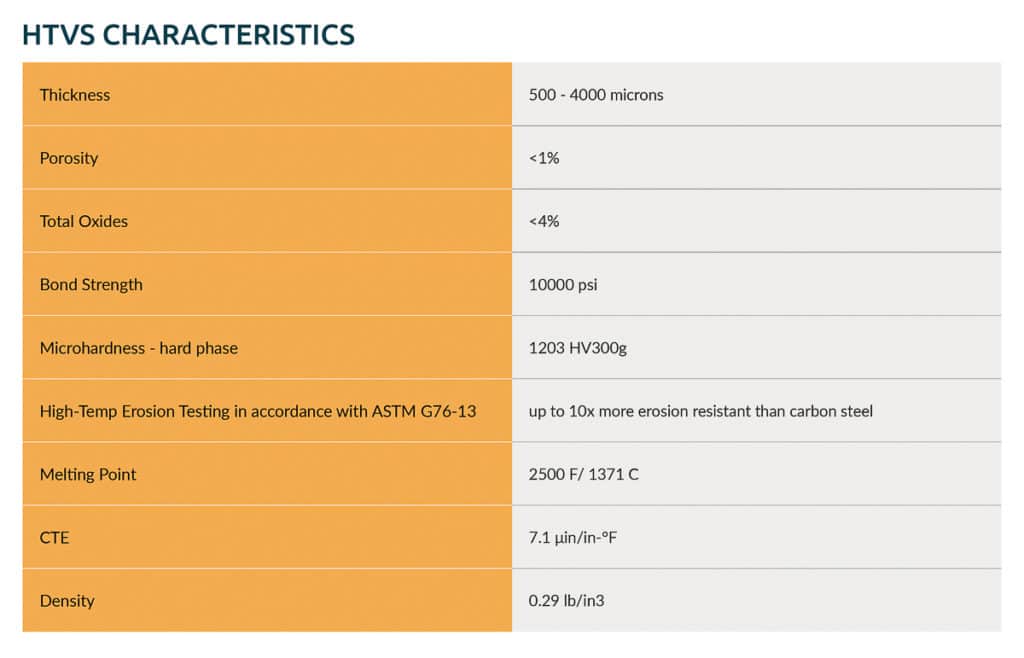

The IGS Material includes high alloy steel specifically designed to protect boiler tubes from high-temperature erosion and corrosion. IGS material recommendations for boilers often include both ceramic and metallic components to produce a homogenous, hard and tough layer. The system provides optimal application and performance properties for various Boilers.

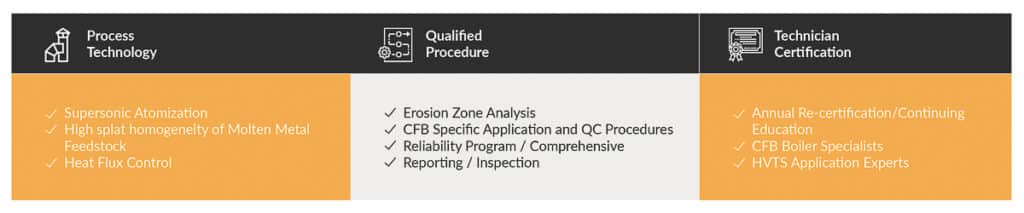

We utilize only true High Velocity Thermal Spray (HVTS) application process, where atomization of the material occurs in a super-sonic gas stream. HVTS process achieves optimal cladding properties needed for reliable and predictable long-term cladding performance.

Our fully trained technicians, stationed in 15+ countries, perform over 2300 hours of work every year during plant shutdowns and turnarounds.

We focus on retaining talent and help our people progress. With over 5000 hours of field experience, our project managers organize and coordinate IGS projects, responding quickly to any emerging needs and maintaining our outstanding safety program.

Our SMART solution creates value not only through the provision of skilled personnel and proprietary fit-for-service HVTS cladding solutions, but also through expert inspection and wastage modelling.

We specify the materials and application thickness both on the first project and during

periodic refurbishment as part of our IGS Monitor and Protect service. These specifications ensure long-term dependable performance.

Why should SMARTGard be your desired solution for protecting your CFB and guaranteeing boiler reliability?

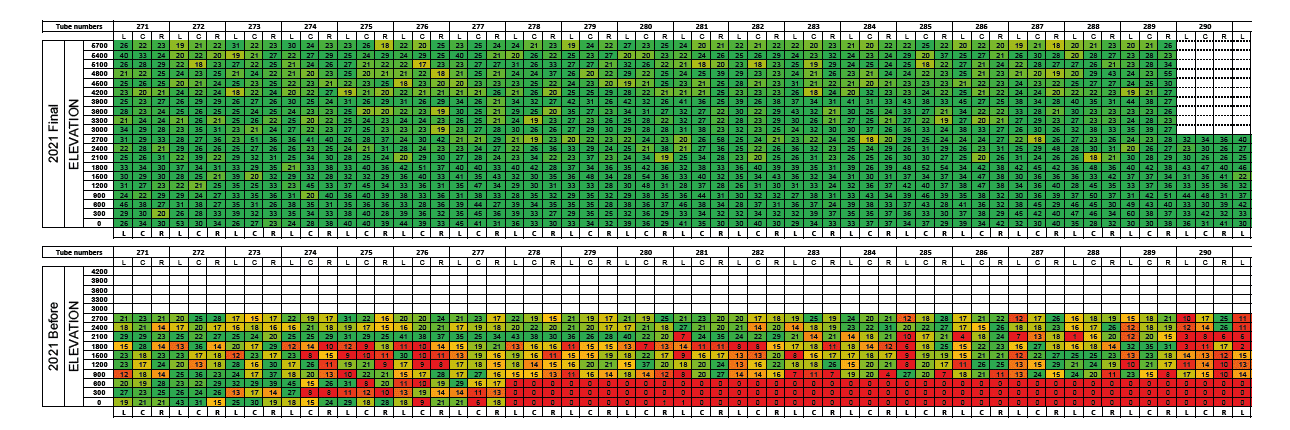

IGS maintains detailed records of all applications and inspections. Records include quality and completion documentation, initial inspection reports and all cladding thickness maps.

Reports are delivered after every project and these records are always available on-demand to monitor the condition of the cladding and to provide critical information for shutdown and maintenance planning and preparation.

What our clients say about IGS’s SMART approach to boiler reliability:

“We went from a varied scope and high man hours to lower man hours and a known scope, which is great for planning for an outage, especially for the budget. Because of our process and work with IGS we didn’t need to replace pressure parts. When you start doing pressure part replacement in circulating fluidized bed boilers, you run into all kinds of issues because you have to do tube alignment.

If the tube alignment is not done correctly, you’re going to end up with erosion or gouging issues for the rest of the life of those pressure parts, that’s extremely

difficult to fix.”

Joel Taylor, Boiler Engineering and Maintenance Specialist. Joel has ensured reliable operation of 7 Circulating Fluidized Bed Boilers between 4 Plants across his 15 Years of CFB Experience.

“IGS brings to table the technical expertise, the understanding, the technical knowledge behind what the people in the field are doing and you’re seeing the results. IGS spends a fair amount of time making sure that they’ve got a good base material and they actually quantify the finish and document that to ensure a sound product, a sound solution and a sound application.

Cladding thickness measurements give you the ability to determine your wear rates and what millage you want to apply and need to maintain to be able to get you from one outage to the next.”

Pete Kline, Plant Manager with 28 years CFB Experience, beginning with the initial utilization of CFB boiler Technology

IGS is here to provide information, answer questions and create an effective solution for your needs.