SMARTGard® Thermal Spray Stops Alloy T24 Fireside Corrosion in Supercritical Boiler

This Power Plant provides steam to nearby industrial facilities using sustainable biomass (such as SBP, GGL, FSC, and PEFC) and industrial by-products (such as bio-propane) to generate power and heat.

SUPERCRITICAL BOILER

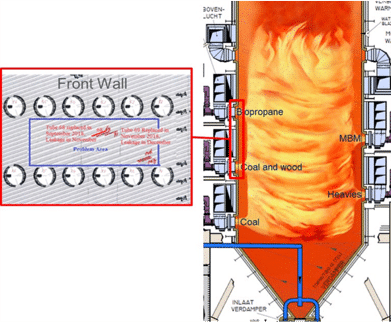

The boiler has five rows of six burners on two sides. These burners are fed with coal, bio-propane, wood, and MBM (Meat and Bone Meal) – animal residue foam injected into the boiler. MBM is very erosive, so the flow is deviated by a deflector plate in the burner, however, the spray still impacts on the opposite wall generating localized erosion and corrosion due to small deposits on the wall facing the MBM burners.

A SUPER ALLOY T24 BOILER

The unique feature of this boiler is that it is one of the first boilers manufactured with alloy T24. T24 material is a novel superalloy, designed for strength at high temperatures that does not require post weld heat treatment (PWHT). This power plant’s aim was to develop a highly efficient supercritical boiler, able to deliver live steam at 6000C.

ALLOY T24 WELDING ISSUES

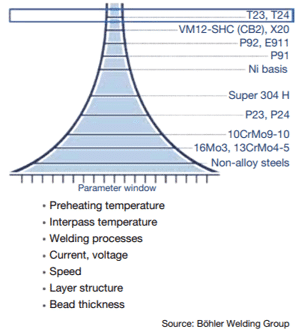

Welding this superalloy is difficult, especially without annealing or post-weld heat treatment. Non-alloy steel, a material used to produce typical boiler tubes, PH 265GH, is the easiest material to weld. The superheater material, 10CrMo9-10, is known as a more difficult material to weld and requires good welders with specific procedures to follow. P91, a refinery furnace tube material, is still more difficult to weld, alloy T24 is even more challenging.

As a result, these first boilers manufactured with T24 suffered many leaks after just a few hundred hours of operation. Welding experts from VGA and other parties involved helped them find the solution, enabling them to erect such supercritical boilers in other plants in Germany and the Netherlands.

EXPERIENCE WITH T24

During the commissioning, the plant experienced forced outages due to the use of T24 in their boiler. Throughout the initial three to four years of operation, they had to stop nearly every couple of months. At this plant, the problem was reinforced by the fact that while the supercritical boiler was designed mainly for coal, it burned increasing amounts of gas, liquid, and solid biomass fuels.

SMARTGard®: IGS HVTS – High-Velocity Thermal Spray

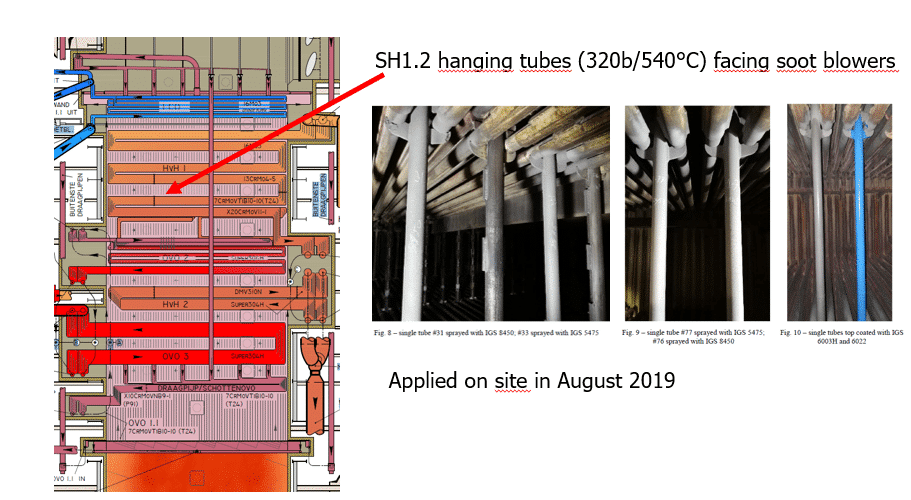

HVTS cladding was also applied onto superheater hanging tubes facing soot blowers. Test areas were installed onto various locations of tube bundles as an alternative to thick metal protection shields.

A LEAK OCCURRED DURING HVTS TESTING

After installing the trial HVTS application in August 2019, another forced unexpected shutdown due to a tube leak occurred in December that year. Although initially it was suspected to be in the IGS clad area, it actually happened in close proximity, in the unprotected area, with the root cause identified having no relation to the installed cladding. Then the boiler continued operating for 16 months without leaks a similar issue.

QUALITY INSPECTION PROGRAMME

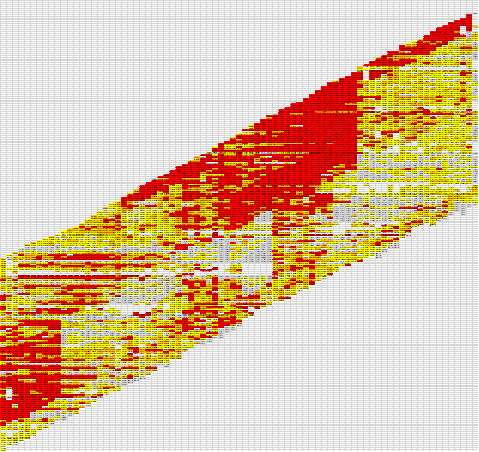

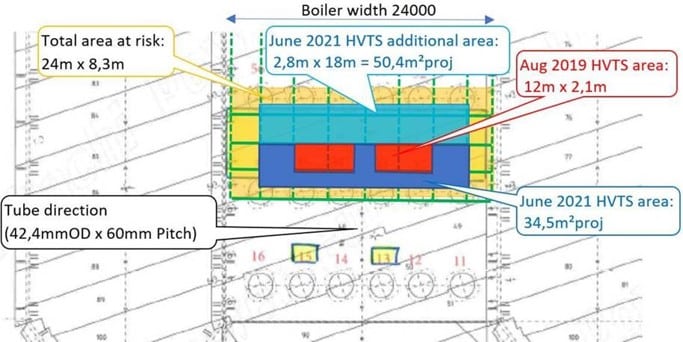

UT Quality inspected HVTS cladding and unprotected tubes. They performed tube scanning using a PEC Scan, Pulsed Eddy Current scanning, that delivers specific tube thickness mapping. This inspection was conducted in 2019 and again in 2021. By subtracting the data collected from the two inspections, they aimed to identify the thinning of the tubes and predict further thinning expected in the next few years.

The area protected by HVTS cladding experienced much less thinning. However, above the protected area, unprotected tubes had shown a thickness loss of up to nearly one millimeter per year.

Right: Thickness change between 2019 and 2021: Red change >0,51 mm, Orange change: 0,31-0,51 mm, Yellow change: 0-0,3 mm

INSPECTION DISCREPANCIES AND RESULTS

When comparing inspection results between 2019 and 2021, the inspection company immediately noticed that some areas appeared to have gained thickness. Cyril Narjoz, IGS Boiler Reliability Expert, commented:

The inspection results were matched with the positioning of the HVTS cladded area. It was a challenge because it didn’t match the red area or the colored area of the thinning. Moreover, to make it a little more complicated, in this boiler, the tubes are not vertical. They are positioned at an angle, spiraling around the boiler. When scanning is performed, they cannot scan horizontally or vertically, but have to follow the tubes. Cyril added:

“You need to keep in mind that first of all, you never read the same point two years later, it’s impossible. Even when you do the reading on the same spot, during the same inspection or the day later, you already can have some significant variation. Readings in 2019 were taken at the three o-clock position, whereas the readings in 2021 were taken at the five o’clock position.”

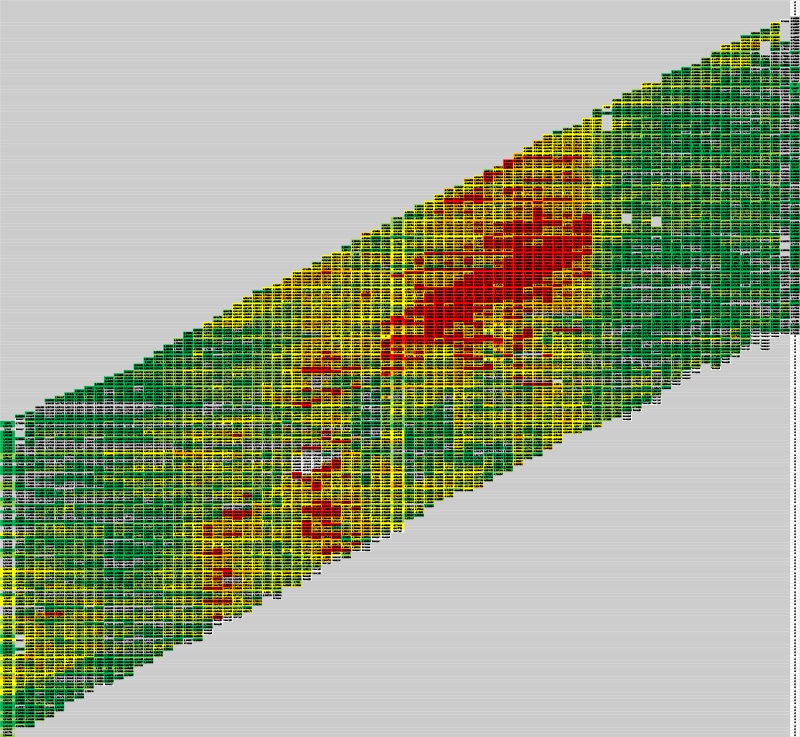

“Nevertheless, what we can see in the area where we applied the HVTS the cladding, there’s much less thinning. And above the area, we have this red zone where we can notice up to nearly one millimeter per year loss that becomes critical.”

FUTURE-PROOFING THE BOILER

Initially, prior to evaluating the readings, the plant had commissioned IGS to expand their HVTS cladding scope to protect a 35 m² surface area finishing the band and protecting a band below. However, after evaluating the readings and the wear rate predictions, the turnaround team decided to increase the scope in the critical area up to 85m² projected surface area.

Right: Thickness Change Prediction for 2023

HVTS APPLICATION IN 2021

The expanded scope was completed in record time by IGS utilizing additional operational resources to speed up the process, with work proceeding simultaneously on several levels. Plant representative said: “We really appreciated IGS’ flexibility during the project to help us meet the shutdown schedule.”

SUPERHEATER TUBES

This project’s second exciting part included the hanging superheater tube bundle with steam at 320 bar / 5400C. These tubes face the soot blowers that are operated at regular intervals to clean deposits of the tube surfaces. Welded metal shields typically protect these tubes from accelerated erosion/corrosion.

Two tubes were clad with IGS HVTS in lieu of protective shields. After two years in service, physical inspection confirmed HVTS cladding to be intact, with no thinning or damage.

Cyril Narjoz commented: “Cladding supplied by a different vendor was also applied and tested in a similar area and performed well. The key difference is – these other tests were sprayed in the workshop before being installed in the boiler. IGS HVTS cladding was applied directly in the field, avoiding cutting and replacing the T24 tubes.”

Right: HVTS Cladded Superheater Tubes Inspected in 2021

CONCLUSION

As T24 material is extremely challenging to weld. One of the major benefits of the IGS HVTS solution is that no welding is involved in its application. Since HVTS is not welded, it does not generate any alteration to the material, distortion, metallurgic impact, or heat-affected zones. HVTS cladding can upgrade corrosion/erosion resistance of metallic substrate without impacting integrity even on a difficult-to-weld material, thus avoiding challenging tubes replacement.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.