On-Site Global Solutions, Delivered with Precision

Why Leading Operators Trust IGS for Critical Asset Protection

IGS is recognized worldwide for its expertise to solve metal wastage issues on site, in situ, while on the critical path of a turnaround. We have the versatility and experience to engage with reliability, inspection and maintenance teams to engineer complex metallurgical solutions.

Our integrated capabilities combine deep field expertise with a world-class Technology Research Center, where we simulate real operating environments to develop precise, data-driven solutions. From advanced HVTS® cladding and proprietary UTEx materials to automated weld overlay and mechanical interventions, IGS delivers engineered surface technologies that extend asset life, reduce maintenance cycles, and restore performance.

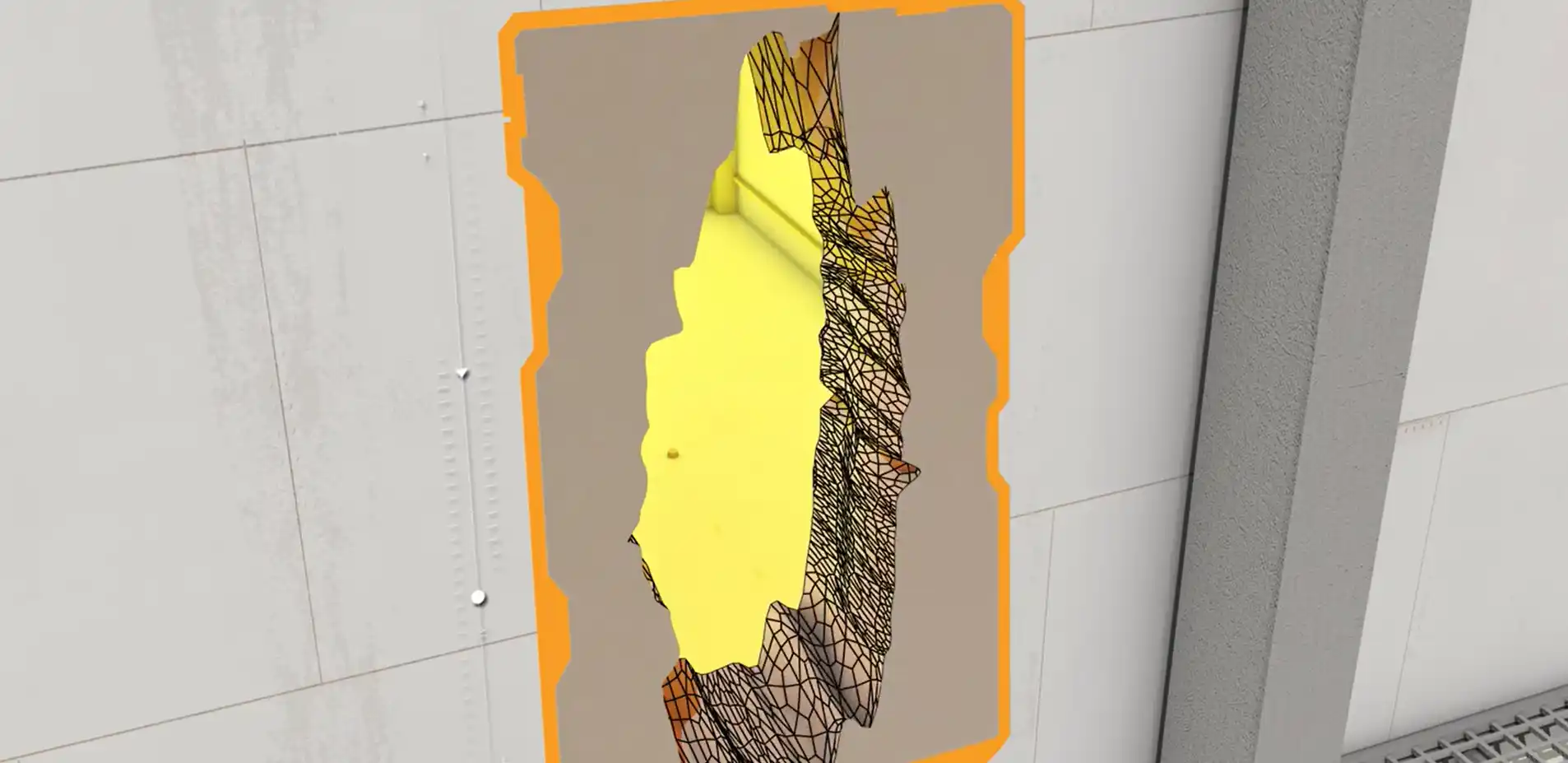

HVTS Alloy Cladding

IGS’s HVTS® High-Velocity Thermal Spray Alloy Cladding solutions upgrade existing metallurgy to higher alloys that provide a barrier to mitigate corrosion and/or erosion in mission-critical equipment.

HVTS is significantly faster to apply than weld metal overlay providing substantial up-front cost reduction and long-term ROI.

HVTS does not create a Heat Affected Zone (HAZ) and therefore will require no Post Weld Heat Treatment (PWHT), saving time and eliminating stresses.

Cetek Ceramic Coatings

Cetek coatings improve radiant efficiency of fired heaters and reduce fuel consumption and/ or boost production, while reducing CO2 and NOx emissions.

Process Tube Coating

Unprotected process tubes will oxidize and scale will grow, inhibiting conductive heat transfer to the feed. Excess firing to overcome this leads to high bridgewall temperatures which ultimately limit the production. Cetek coatings eliminate oxidation for approximately 2 turnaround cycles and maintain peak heat transfer efficiency.

Refractory Lining

Cetek’s high emissivity coatings for refractories create a near ‘Black Body Enclosure’ inside the fired heater, which maximizes radiant heat transfer efficiency to the process tubes.

Our Welding Services

Extend asset life and safeguard critical infrastructure with IGS’s industry-proven automated welding services.

Hot-tek Online Services

IGS’s Hot-tek™ services facilitate maintenance,

inspection and cleaning of the fired heater while it

is in operation. No Shutdown required.

- Hot Convection Cleaning

- Hot Tube Descaling

- Hot Refractory Repair

- Hot Vacuum Service

- Hot Inspection Service for fired heaters

- Hot Tube Stabilization

Often, multiple Hot-tek™ Services are employed simultaneously during an application to achieve the best result, with the most convenience for the client.

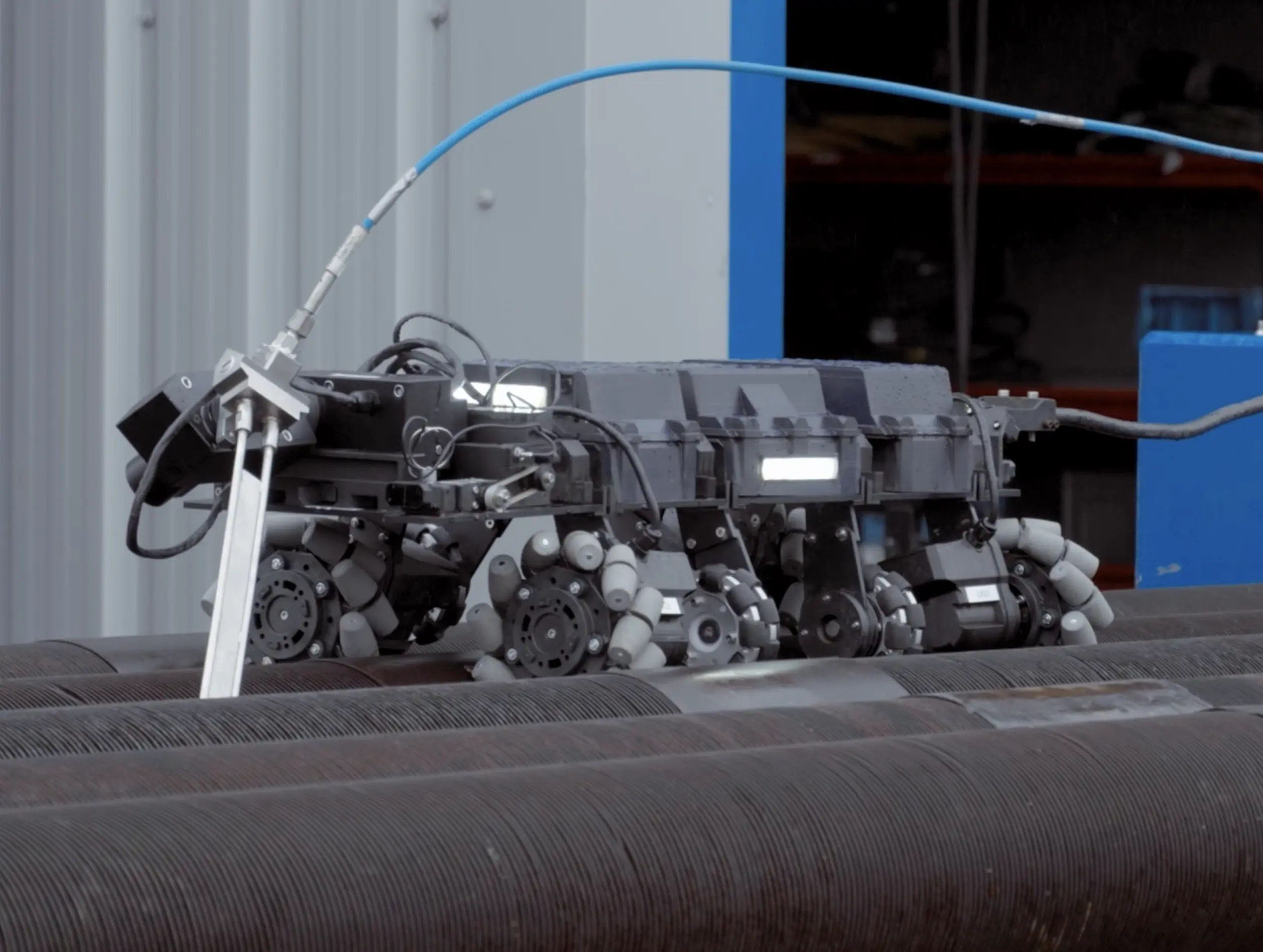

TubeTech™

Engineered Convection Section Cleaning

TubeTech™ has spent more than 30 years working at the forefront of innovation in heat exchanger cleaning technologies across heavy industrial sectors, providing a premium service for the biggest names in the industry and building a reputation as the ‘go-to’ solution for even the most challenging and critical fouling projects.

With multi-million R&D investment, TubeTech™ has developed a reputation for leading innovation. Investing heavily in developing technology, these engineered solutions make cleaning safer, more thorough, tackle emissions and deliver guaranteed results in performance.

95% clean guarantee even on the most fouled assets.

IGS TUFFss ONLINE TSA

TSA (Thermal Sprayed Aluminium) provides lasting (>20 years) corrosion protection by acting as a barrier coating, passivating the surface.

Plant operators no longer need to make tradeoffs between turnaround duration and asset integrity as IGS TUFFss ONLINE TSA can be safely applied all year round, between shutdowns and turnarounds. Developed in a 2-year R&D program with Royal Dutch Shell, IGS has validated live-plant applications at Shell Pearl and Nigeria LNG/Royal Dutch Shell, among others.

As equipment within refineries, petrochemical plants, and other facilities continues to age, the demand for maintenance solutions that can be applied safely all year round is growing. Plant operators are looking to IGS to utilize their global footprint and experience to deliver innovative solutions safely and efficiently.

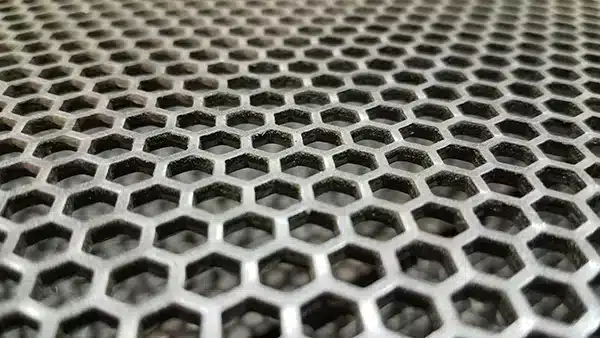

SCR Solutions

IGS SCR Solutions specializes in comprehensive cleaning solutions. We supply Large Particle Ash (LPA) Screens, Turning Vanes, Air Cannons, and Secondary Screens to a variety of industries and applications. By combining these products to work in unison, we are able to provide customized solutions with unmatched warranty protection.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.