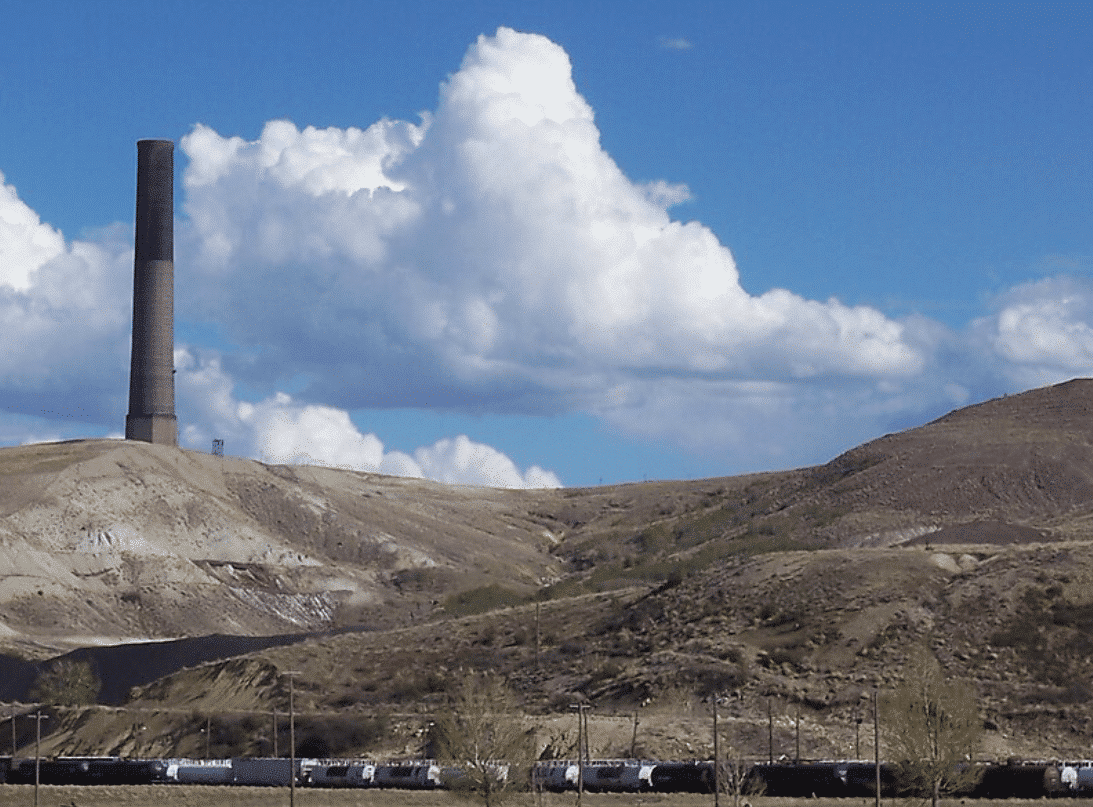

Stacks

Stack Corrosion

Stacks and chimneys are exposed to combustion gases, moisture, and acidic compounds. The top area of the stack can experience severe corrosion and failure, especially around flanged joints. The unlined carbon steel stack will require frequent and costly part replacement.

Corrosion Mechanisms

Increased sulfur in fuel and alternative fuel sources have all contributed to the corrosion problems. Following 4 or 5 years of uncontrolled corrosion, a stack can face wall thickness loss, causing the structure to become unsafe.

The Solution to Stack Corrosion

Stack corrosion can be effectively mitigated with IGS HVTS®.

Developed for safe on-site application IGS HVTS® can be used to permanently stop metal wastage, preventing the need to cut and replace the metal parts or continuously reapply low-performance coatings.

Global Metals & Mining smelters benefit from this innovative metal wastage solution in their pyrometallurgical furnaces, waste heat boilers, baghouses, off-gas ducting, ESPs, and stacks.

Proven Experience

IGS has protected mission-critical process equipment against corrosion and wear damage for over 20 years. IGS has successfully provided over 400,000 m2 of surface protection across more than 3,000 projects in over 30 countries on 6 continents.

Quality, Safety and Reliability

Fully trained and certified in-house personnel provide turnkey installations, operating under robust HSE and QMS programs, providing our customers with the safest and most reliable surface protection service available. Our customers attest that our safety-first culture noticeably sets IGS apart from most industrial contractors.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.