Cetek’s patented Dual Emissivity Ceramic Coating technology manipulates and optimizes the heat flux distribution in DCU heaters which are susceptible to coking inside tubes.

We designed the dual emissivity coating system to maximize benefits based on the coking pattern of the Delayed Coker firebox.

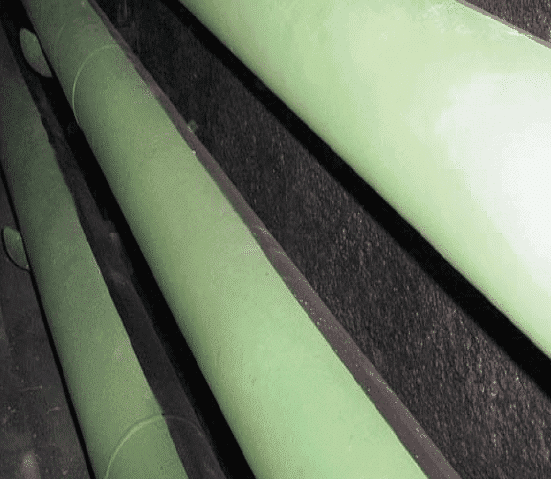

The process consists of the application of coatings to the refractory. We also remove all tube scale, and install a uniform, dual emissivity ceramic coating system to the tube surfaces.

This dual emissivity coating system effectively shields the tube surfaces in high heat flux areas but increases heat absorption in lower heat flux areas. This reduces coking rate while at the same time eliminating uneven scale formation, thus allowing accurate tube metal temperature measurements.

In coking sensitive fired heaters, etc., the coking reaction is initiated by high tube wall temperatures. The coke is laid down on the internal surface of affected tubes and leads to progressive increases in tube metal temperature and accelerated coke formation and oxidation/scale formation on the external surfaces. The result is a reduction in production and a necessary shutdown, or halt to decoke the tubes.

Cetek’s dual emissivity ceramic coating system allows an effective heat flux manipulation, reducing tube metal temperatures in high heat flux areas and reducing the rate of coke formation. This results in an extension of run length between decoking activities.

The process consists of the application of high emissivity ceramic coatings to selected areas of the refractory surfaces and a combination of high and low emissivity ceramic coatings to the tube surfaces.

All Cetek coatings, including Dual Emissivity and High Emissivity Coatings, are applied by Cetek’s highly trained, experienced technicians, following thorough cleaning of the tube surfaces. Coating systems are available for every type of metal and refractory substrate as well as process temperature.

The coatings are inert, non-catalytic, and water-based, offering a complete environmentally safe process improvement. The service is supported by a superior Health & Safety Program, yielding a safety record better than industry standards.

IGS is here to provide information, answer questions and create an effective solution for your needs.