Ethylene Crackers

Ethylene Steam Cracker Efficiency

Ethylene Steam Crackers have the greatest running cost for Olefin Production. If any one of these heaters is 1 or 2% inefficient it can consume an additional $1M in fuel over a year or result in $millions in lost revenue.

IGS Pyrolysis Furnace Efficiency Solutions deliver:

- Improvement in processing efficiency

- Energy/Fuel Savings

- CO2 and NOx emission reduction

- Elimination of operational limitations (excess flue gas temperature, firing duty, draft)

- Ceramic Fiber Refractory encapsulation

White Paper: A Techno-Economic Overview of Fouling in Steam Crackers and Available Solutions

Our Solutions

TubeTech™ – Engineered Convection Section Cleaning

Hot-tek™ – Online Maintenance & Emergency Services:

- Hot Convection Cleaning

- Hot Inspection Service

- Hot Vacuum Service

Cetek Efficiency Coatings

Refractory Encapsulating Ceramic Coatings for Ceramic Fiber

Cetek provides a distinct benefit in treating refractory surfaces with a high temperature ceramic coating. The coating reduces ceramic fiber dusting and increases refractory lifetime which results in fuel savings and an improvement in the convection section cleanness, which helps keep the pyrolysis furnace efficiency at the highest level.

The Problem

Ceramic fiber refractory of Ethylene Furnaces is often identified as the main source of fouling.

Over time, refractory ceramic fiber becomes friable. This friable dust is entrained in the post-combustion flue gases and gets carried downstream, fouling catalyst tubes, convection section tubes and SCR catalyst banks.

The Solution

Cetek’s Encapsulating Ceramic Coating system stops fiber dusting Ethylene Furnaces, delivering optimum performance and reducing CO2 and NOx emissions.

The Benefits

- CO2 and NOx emission reduction

- Fuel savings

- Ceramic Fiber Refractory encapsulation

TubeTech™

Engineered Convection Section Cleaning

TubeTech™’s Robotic Ethylene Furnace convection section cleaning service is recognized by world-leading refining and petrochemical companies as the most effective technology to achieve OEM performance clean fired heaters.

95% clean guarantee even on the most fouled assets.

The Problem – Steam Cracker Convection Section Fouling

Fouling

Ethylene Cracking Furnace fouling is a costly problem for olefin manufacturers around the world. Heater intake collects 1 ppm airborne particulate whilst in service, which results in deposits of up to 2.5 tonnes over 12 months either landing in or travelling through the heater.

These deposits most commonly land:

- In the base of Radiant Section

- On Convection Tubes

- On the SCR Catalyst

- In the Air Pre-Heater

Fouling results in:

- More Fuel Consumed

- Increased Emissions

- Higher Stack Temperature

- Heat Stress on Tubes, uneven expansion, and heat distribution

- More Running Costs

- Potential Tube Failure

The Solution – Robotic Ethylene Furnace Fouling Removal

TubeTech™’s Pyrolysis Furnace convection section cleaning service is recognized by world-leading refining and petrochemical companies as the most effective technology to achieve OEM performance clean SMRs.

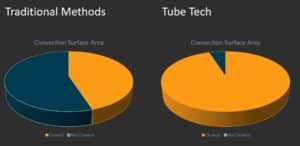

Traditional cleaning methods are only able to clean 30-45% of the total fouled area. TubeTech™, has developed a rover system that penetrates deep between tube rows to remove even the most stubborn fouling.

The Benefits

- Removes 95%+ of Fouling

- No Refractory Damage

- Safety – No Man Entry

- Reinstates Thermal Efficiency and Reduces CO2 Emissions

- Extends Asset Life due to Reduced Stack Temperature

- Rapid Global Mobilization

Read: Fired Heater Convection Bank Cleaned Robotically at German Refinery

Hot-tek™ Services for Ethylene Cracking Furnaces

Online Maintenance & Emergency Services (During the Heater’s Normal Operation)

Hot-tek™ is the industry leader in hot maintenance and online Ethylene Furnace repair and cleaning techniques and holds multiple patents on the approach, methods, and tools used to carry out these services. The approach is customized for every client’s needs. Often, multiple Hot-tek™ Services are employed simultaneously during an application to achieve the best results.

Hot Refractory Repair in a roof of a Steam Cracker

The Problem

Failure of refractory material can lead to energy wastage, poor performance and even complete shutdown of your Ethylene Furnace.

The Solution

Hot Refractory Repair Services may be made gaining access through the heater steel shell directly behind the damaged area. Minimal openings are used to insert specially designed components to support the repair material. This technique offers a semi-permanent repair method lasting at least until the next planned turnaround.

The Benefits

- Restore Production Rates

- Fast, Effective Short-term Solution

- Avoid Costly Unplanned Shutdowns

Hot Convection Cleaning in a Pyrolysis Furnace

The Problem

Low steam production, low process pre-heat, and high stack temperatures are some of the symptoms of fouled tubes within a convection section.

Fouling results in:

- More Fuel Consumed

- Increased Emissions

- Higher Stack Temperature

- Heat Stress on Tubes, uneven expansion, and heat distribution

- More Running Costs

- Potential Tube Failure

The Solution

Hot Convection Cleaning process removes convection section tube fouling & scale during furnace operation. The tube cleaning process uses consumable abrasive media projected through specially designed application lances to blast away years of accumulation, while the heater is in service.

This emergency or intermediary solution prevents losses associated with taking the heater offline. However, we advise a Planned Preventative Maintenance (PPM) approach, and our TubeTech™ service provides industry-leading offline cleaning services to prevent emergency cleaning situations.

The Benefits

- Increased heat transfer efficiency in the convection section

- Increased steam production

- Increased process pre-heat

- Lower stack temperatures

Hot Inspection Service in an Ethylene Furnace

The Problem

Sometimes, an issue can arise in high temperature fixed equipment, but you can’t see the cause or the exact location of the problem. We designed and developed Cetek’s Lancescope™ heater inspection tool for just this situation. It allows a high-temperature furnace inspection to be carried out to determine the scope of the problem, often avoiding an expensive shut down of the heater.

The Solution

Cetek’s Lancescope™ system provides real-time, close-up, or wide-angle views of virtually any area inside a fired heater, or other high-temperature equipment while it is still in operation.

The hot inspection service for fired heaters uses a state-of-the-art digital camera system, which provides clear, detailed images of problem areas up to 3000°F (1650°C). The furnace inspection system can be inserted into openings as small as 2.75” (7cm) and reach up to 30ft (10m). In applications below 1000°F (540°C), the heater inspection system provides illumination via a high-temperature light source for optimum clarity.

Thorough inspection provides data needed for other Hot-tek™ online services.

The Benefits

- Performed while unit is in operation

- Provides insight for production availability

- Identifies damage in early stages

- Reduces maintenance costs

- Minimizes repair down time

- Maximizes production

Hot Vacuum Service in an Ethylene Furnace

The Problem

Over time, debris such as ceramic fiber inorganic dust and combustion by-products entrained in the flue gas accumulate on the upstream face of the SCR catalyst. This debris hinders gas flow through the catalyst increasing the pressure drop across the SCR unit. To overcome this effect, the induced draft fan utilization must be increased consuming extra energy. After the fan has reached max capacity, production must be reduced to decrease the pressure drop across the SCR.

The Solution

IGS’ Hot Vacuum Service cleans catalyst banks in SCR units to Ethylene Furnaces and other fired heaters. SCR catalyst banks are cleaned during operation with no interruption to production, offering a rapid payback on associated costs.

Our online SCR catalyst cleaning service removes pluggage and fouling from SCR screens, immediately improving catalyst reduction system efficiency.

The Benefits

- Prevents costly unplanned shutdowns

- No disruption to process

- Maximizes catalyst efficiency and lifetime

- Increases plant uptime and reliability

Read: ‘Hot Vacuuming Prevents Emergency Shutdown’ Case Study

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.