Convection Section Fouling Removal

A Smart Fouling Removal Service to Restore Fired Heater Efficiency

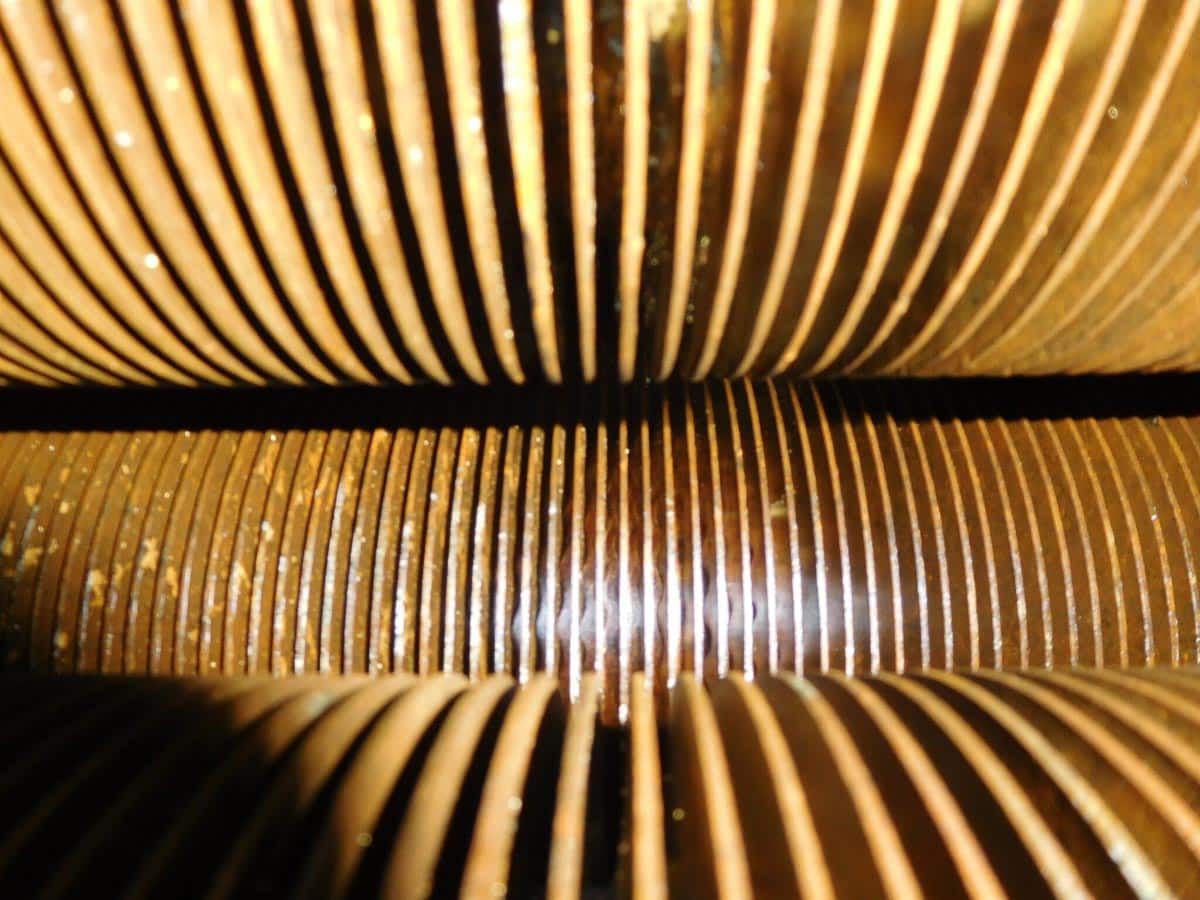

If your facility is experiencing an increase in stack temperature or reduced performance or output, it could be a sign of furnace convection section fouling. When fouling occurs, it limits the thermal efficiency of the fired heater which results in an increase in fuel consumption as the heater must work harder to achieve the required results.

TubeTech™’s fired heater convection section fouling removal service is a proven turnkey solution which guarantees to remove 90%+ fouling, restoring fired heater performance and reducing CO2 emissions and fuel consumption.

- 90%+ fouling removed guarantee

- 2-5% increase in thermal efficiency*

- Up to 15% reduction in CO2 emissions*

- ROI within 2 months

- Average* results reported by TubeTech™ clients

I’m here to help

Scott Donson

IGS Subject Matter Expert

Technical Information

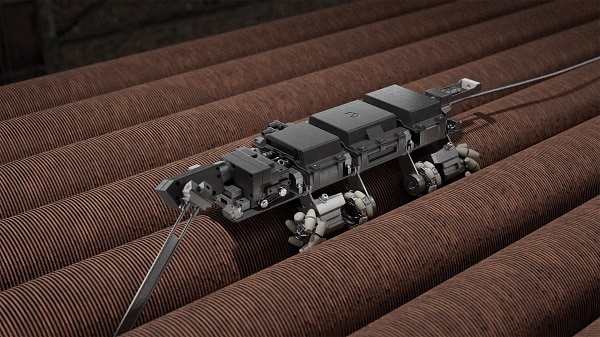

As a result of a comprehensive research and development programme, TubeTech™ has developed a patented robotic fouling removal system which is used by major petrochemical and refining plants around the world. On average, our clients report a 3-5% increase in thermal efficiency and up to 15% reduction in CO2 emissions.

The robotic system can access even the most difficult-to-reach convection banks. It is remotely controlled by an experienced technician and the engineered lance penetrates deep between each tube row to remove the toughest fouling.

TubeTech™ Fired Heater Fouling Removal Case Studies

Thermal Efficiency Increased by 3% at Turkey Refinery

The refinery had been experiencing reduced performance due to fouling on convection bank tubes within a steam methane reformer.

- Hydrogen production cost decrease resulted in ROI in less than 60 days

- Flue gas temperature decreased by 3%

- Steam production increased by 20%

Robot Restores Stack Temperatures in Holland

The convection section of the fertiliser production plant’s Primary Reformer Furnace was heavily fouled as it had never been cleaned before and fouling build-up was affecting efficiency.

TubeTech™ was able to deploy its patented robotic fouling removal system to penetrate and clean deep between each tube row whilst protecting the asset from refractory damage.

- 95% of the asset surface area was accessed

- Stack temperatures were restored

- 90%+ of fouling was removed

Free Whitepaper: How to Cut Emissions & Fuel + Increase Capacity in Fired Heaters

Key features include:

Smart digital sensors

Automatically adjusts water pressure to deliver fouling removal results whilst protecting asset materials. The robot also adjusts to warped tubes.

Adjustable lance and track

The robot can access every row of a convection bank regardless of size. As it is remotely mounted, there is no need for man entry so fouling removal can be completed safely.

Pre-programmable

The robot is pre-programmed with asset information prior to arrival on-site, saving valuable time and ensuring that fouling removal is precise and thorough.

Records images and videos

An HD camera records footage of the fouling removal taking place and identifies any blockages or areas of concern. These can be used for reporting purposes and future fired heater maintenance planning.

What do our customers say?

“The service they provide, in my opinion, is second to none. Technically and technologically TubeTech™’s knowledge surpasses any company I have personally met that supplies this kind of service.”

Process Engineer, Major European Refinery

Contact a Fired Heater Furnace Expert Today

If you are experiencing a drop in stack temperature, thermal efficiency or output, our team can help identify and solve the issue.