Texas Tower (VCFE) Fouling Removal

Restoring Texas Tower (VCFE) Performance through smart fouling removal and unblocking services

TubeTech’s Texas Tower (Vertical Combined Feed Exchanger, Feed Effluent Exchanger) fouling removal service combines more than 30 years of experience with patented technologies to deliver a reliable turnkey solution.

Common challenges include HCFE fouling location, asset accessibility, unknown deposit materials, safety, and costs. When taking equipment offline it is essential to conduct fouling removal quickly, and safely, and use techniques which deliver maximum results. TubeTech™ has extensive experience in the removal of fouling from texas towers at processing facilities worldwide.

I’m here to help

Scott Donson

IGS Subject Matter Expert

Watch: Vertical Combined Feed Exchanger Cleaning

What is a Texas Tower (VCFE)?

Texas Towers are shell and tube heat exchangers, also known as Vertical Combined Feed Exchangers (VCFEs), Feed Effluent Exchangers, or Hot Feed Effluent (HCFE) Exchangers, are vertical combined feed exchangers that play a crucial role in the efficiency of hydrocarbon processing units. Over time, fouling can significantly reduce their performance.

Why Should Fouling be Removed from Texas Towers (VCFEs)?

All heat exchangers, including Texas Towers, Vertical Combined Feed Exchangers (VCFEs), Feed Effluent Exchangers, and Combined Feed Exchangers, need to have fouling removed as often as necessary to avoid production losses and unplanned outages caused by HCFE fouling.

Although Texas Towers require less frequent fouling removal than other types of heat exchangers, it is imperative that a planned preventative maintenance (PPM) schedule is in place to ensure that performance and capacity remain constant.

How Often Should Fouling be Removed from Texas Towers (VCFEs)?

Texas Towers are designed to be relatively ‘clean’ exchangers. This means that they can often go 7–10 years without the removal of fouling and not experience a drop in performance. However, performance deterioration can be a gradual process which eventually leads to real problems due to HCFE fouling buildup.

We would recommend removing fouling from Texas Towers, VCFEs, or Feed Effluent Exchangers once every 7 years to prevent a drop in performance with its associated economic impact.

TubeTech™ Texas Tower (VCFE) Fouling Removal Case Studies

VCFE tubes unblocked with only 2m headroom

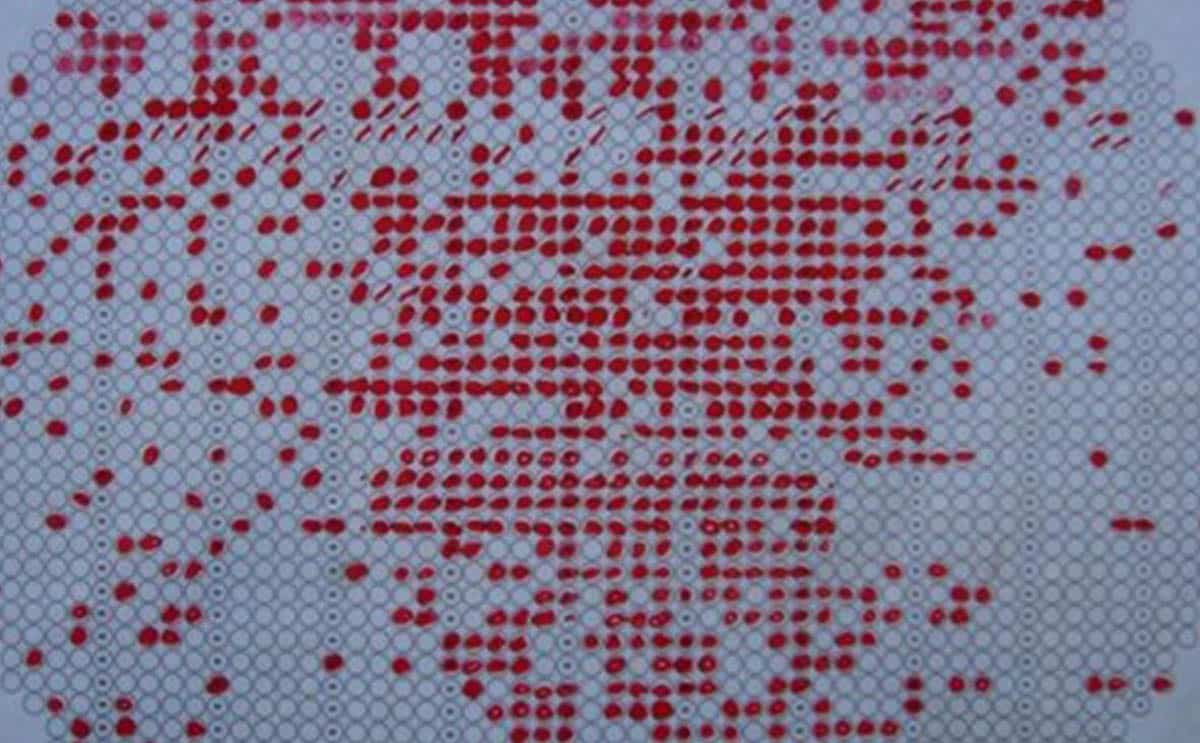

The Caribbean refinery was experiencing a significant drop in performance due to an unknown number of tube blockages.

- Client estimated 12% of over 2,000 tubes were blocked

- TubeTech™ inspection found that nearly 1,000 tubes (50%) were blocked

- In 5 days TubeTech™ successfully unblocked more than 300 tubes to allow the VCFE to be returned to production – with a further 750 tubes to be cleared during the next turnaround

“TubeTech™ showed great resourcefulness – our VCFE was unblocked and inspected to production standard without overrunning the shutdown period.”

Read more

Exchanger thermal efficiency restored

The large Asian refinery was suffering from a significant performance drop caused by tube bore blockages. TubeTech™ worked during a critical path, there was a limited time frame in which to complete the HCFE fouling removal.

- Traditional fouling removal methods including chemicals were attempting by previous contractors without success

- Time limited fouling removal to only 7 shifts – traditional water jetting required up to 50 shifts

- Super high-pressure pumps 55,000psi capability

Read more

Two Texas Towers (VCFE) Restored Five Times Faster

Safety, speed, and cleanliness were the most important factors for the French refinery. With a critical shut down schedule, the client was eager to have both the shell side and tube side of both vertical combined feed/effluent exchangers cleaned within a 6-day window.

- Previous fouling removal had required 24 shifts to restore each of the two combine feed/effluent exchangers

- TubeTech™ required just 5 shifts

Read more

What do our customers say?

We have used local and international contractors before, but with mixed results. Since using TubeTech™ to remove fouling from the VCFEs, for the first time since the refinery was commissioned, the Texas Towers on the CCR Platformer are giving us near-to-original efficiency and productivity.

Senior Shutdown Manager, Middle Eastern Refinery

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.