Enhancing Flare Line Durability with Field-Applied Alloy Upgrades

In the demanding environments of oil and gas extraction and refining, flare lines play a crucial role in managing excess gases. Yet, these vital components are under constant threat from corrosion induced by H2S, CO2, and other corrosive agents present in wet gas systems. Traditional corrosion mitigation strategies often prove inadequate in the face of such harsh conditions, leading to premature failure, costly unplanned shutdowns, and significant safety risks.

Flare Line Corrosion Mechanisms

- The presence of corrosive contaminants in the flare gas stream e.g. hydrogen sulfide (H2S), ammonia (NH3), and chlorides. This can lead to sulfidation, ammonium chloride corrosion, and hydrogen-induced cracking.

- The cyclic nature of flare operation; at minimal or no flow, internal surfaces are exposed to corrosive vapors resulting in localized corrosion, pitting, and accelerated metal loss.

- Rapid temperature fluctuations during flaring events can cause thermal stresses and cyclic loading, leading to potential fatigue and cracking of the flare line material.

- Improper flare gas recovery or inadequate purging practices can lead to the accumulation of corrosive species within the flare lines.

The Consequences of Flare Line Corrosion

- Compromised structural integrity, increasing the risk of leaks, ruptures, or even catastrophic failures.

- Reduced flare system efficiency could impair its ability to safely combust and dispose of process gases, leading to emissions of hazardous compounds into the atmosphere.

- Disruption of refinery operations, impacting production schedules and profitability.

- Compromised regulatory compliance if corrosion-related emissions exceed permissible limits, potentially resulting in fines and legal consequences.

Register now for a FREE WEBINAR

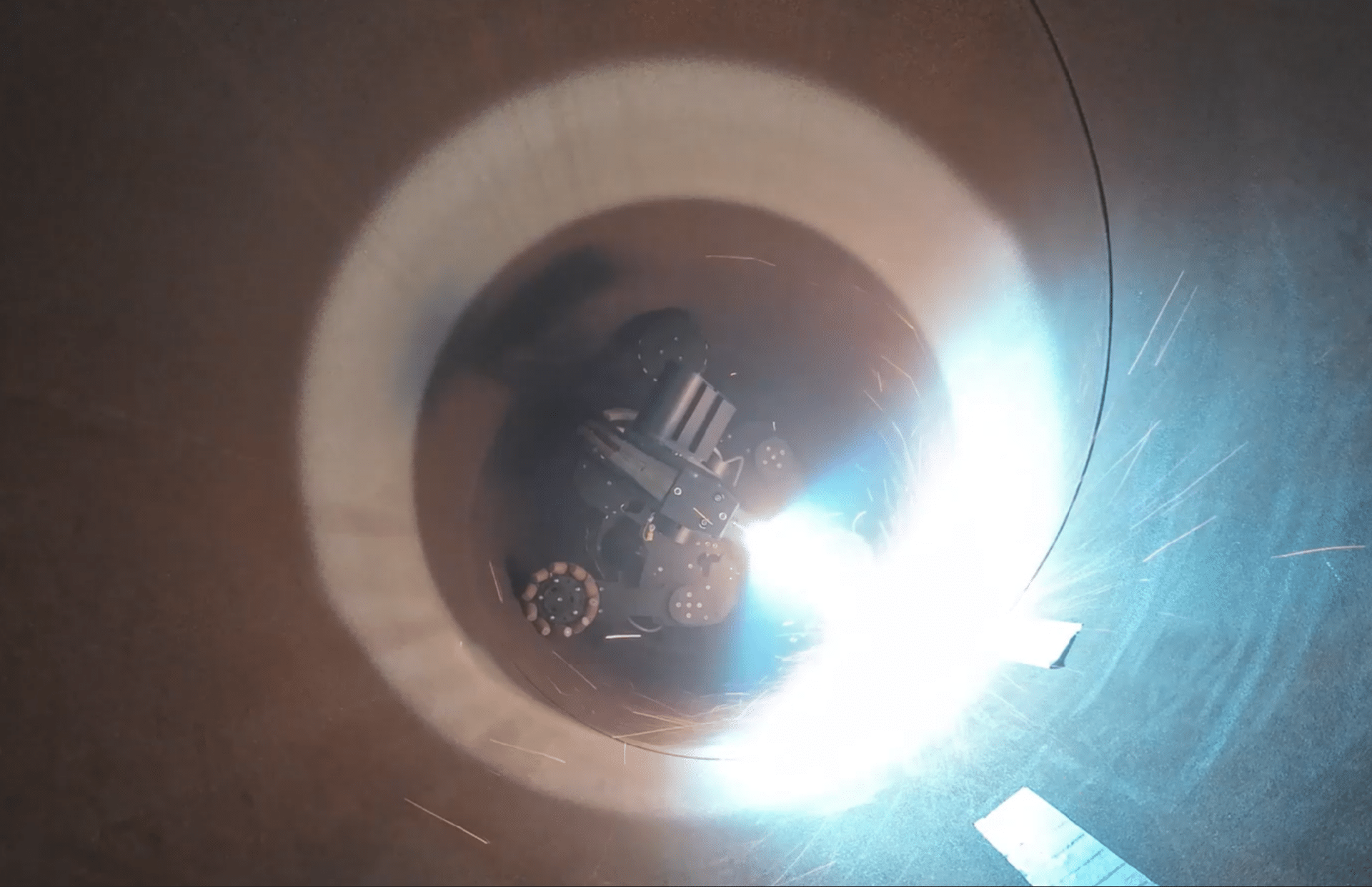

How can a field-applied Metalspray PipeID Rover protect pipeline sections and weld seams from corrosion?

Metalspray PipeID Rover System Mitigates Flare Line Corrosion

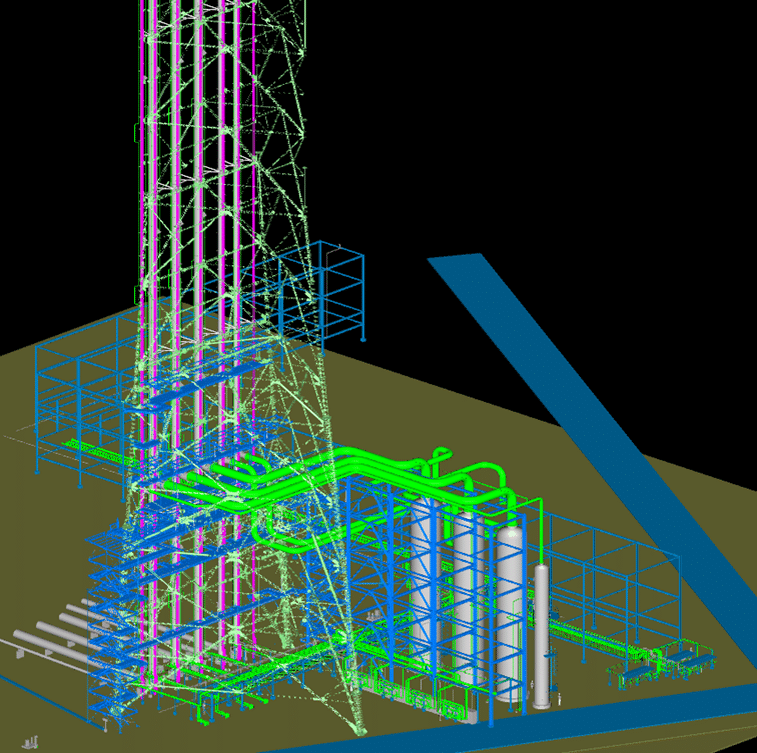

Integrated Global Services (IGS) introduces an advanced corrosion control technology tailored for flare lines – the Metalspray PipeID Rover system. This field-applied, no-man-entry solution leverages the proven effectiveness of on-site alloy upgrades to combat the pervasive issue of corrosion, extending the operational life and reliability of flare lines.

How It Works

The Metalspray PipeID Rover is a revolutionary self-propelled system designed for internal high alloy cladding for corrosion protection of flare lines. It navigates through pipelines, applying a durable high alloy cladding to interior surfaces without the need for direct human intervention. This approach ensures comprehensive surface preparation, alloy application, and quality control in environments previously considered challenging or impossible to treat effectively.

Key Benefits

- Enhanced Durability: Our alloy upgrades significantly increase the resistance of flare lines to common forms of corrosion and wear, ensuring longer service life.

- Operational Efficiency: By reducing the frequency of maintenance and the risk of unplanned shutdowns, our solution helps maintain continuous, efficient operations.

- Safety and Environmental Compliance: Strengthening flare line integrity reduces the risk of leaks and emissions, supporting safer workplace environments and adherence to environmental regulations.

- Cost Savings: Extending the lifespan of existing infrastructure with our Metalspray technology translates into substantial cost savings over time, minimizing the need for expensive replacements and repairs.

Why Choose IGS?

At IGS, we’re committed to providing innovative solutions that meet the unique challenges of the oil and gas industry. Our Metalspray PipeID Rover system is just one example of how we’re pushing the boundaries of technology to protect and enhance critical infrastructure. With a track record of success and a team of experts dedicated to excellence, we’re here to ensure your operations are safeguarded against the threats of corrosion.

Ready to Protect Your Flare Lines?

Discover the difference our Metalspray PipeID Rover system can make for your flare line durability and overall operational resilience.