Biomass and waste-fueled CFB boilers have been developed based on the advantages of CFB design, offering high combustion efficiency, low emissions and high fuel mix flexibility. Typically designed for medium or large installations, CFB boilers produce steam by burning biomass, recycled biomass, pre-treated industrial or urban waste.

This design spectrum also includes the conversion of units initially design for coal or lignite. Fuel flexibility allows the reduction of related costs and opens up operational flexibility to both renewable energy sources and conventional fuels.

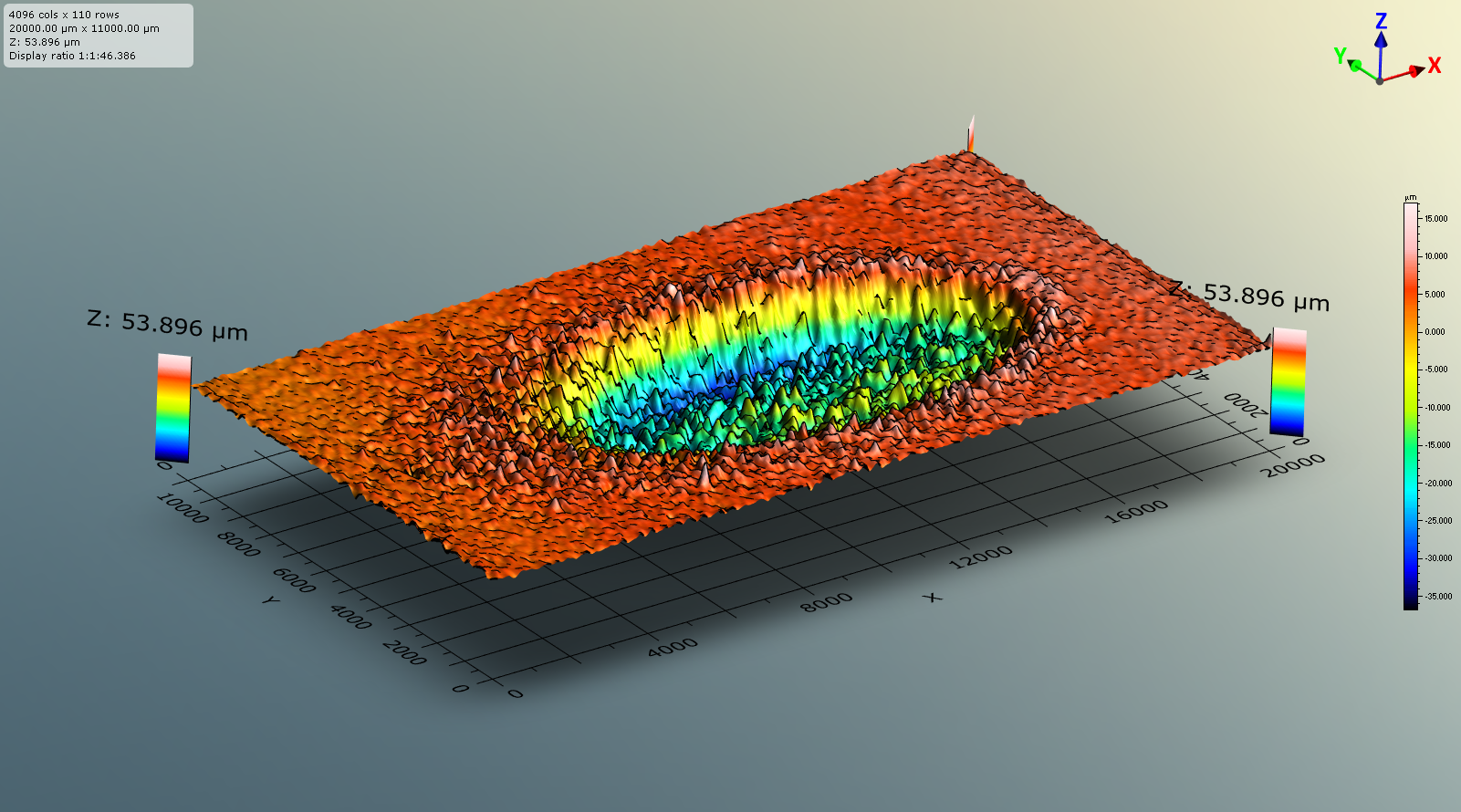

Erosion is the main challenge for circulating fluidized bed combustion, with hard particle circulation into the boiler, so most designs use refractory protection in the furnace area. We apply erosion resistant coating on the evaporator surfaces to prevent thickness losses on the tubes.

With fuel containing plastics and other chemicals generating Chlorine, Sulphur, and other alkali and heavy metals, the corrosion can dramatically increase the thickness loss rate.

Several WtE plants designed with CFB met reliability challenges leading to many unexpected outages and high maintenance cost so despite the efficiency and emission benefits, this technology is less developed for corrosive fuel, but material improvements can lead to longer life of the circulating fluidized bed boilers.

HVTS cladding has been used for decades in erosion application inside CFB boilers fueled with coal or lignite. High Velocity Thermal Spray is designed for applying a metal layer with very low porosity and sealability to better protect the base metal in high corrosion environments.

This technology allows the use of solid or cored wire, enabling easy material modification compared to technologies depending on the market available solid wire. Since the process doesn’t generate any dilution with the base metal, the quality of the coating is not altered by chemistry mix.

IGS brings to bear decades of experience to bring you the best and most efficient technology for field application:

Integrated Global Services Europe provides on-site thermal spray coating inside WtE and Biomass CFB boilers in all countries of Europe, including the UK, Germany, the Netherlands, Italy, Switzerland, and France, from our operations center in the Czech Republic. We spray coatings in the United States, Middle East, Japan, South-East Asia, as well as Africa.

Find out more about SMART Gard solution characteristics, alloy features, technological benefits, erosion resistance, and much more.

CFB boilers are preferred for their high efficiency and flexibility in fuel usage, thus high pressures and temperatures are found within these units. The more corrosive agents introduced through the fuel, the higher corrosion will develop on the non-protected heat exchange steel surfaces of the super-heaters.

Most corrosion protection mechanisms consist of generating a corrosion barrier on the base metal by forming an oxide layer. Inside CFB boilers this layer is quickly eroded, forcing the formation of another layer and consequently leading to erosion-corrosion phenomenon. Erosion-corrosion thinning can be quick with soft or poor erosion resistance materials.

With such conditions it can be expected that ashes will not build up so less corrosion by salts occurs. This is true for the surfaces seeing high flow speed, but in some areas the ashes can build up and typical under ash salt corrosion can develop due to flow turbulence.

Even without an ongoing erosion mechanism, salt corrosion will depend on ash composition and tube skin temperature. With materials softening with temperature, erosion resistance performance of most materials declines and is something that must be addressed in CFBs and WtE units.

(Picture, right: an example of CFB Boiler erosion)

The hot molten salt corrosion process starts when the temperature of the tube surface is higher than the melting point of the precipitated salts so that salt melts directly on to the metal surface. The resulting reaction dissolves existing oxide layers, which let the corrosive chlorine gas dissipate to the metal surface.

Hot salt melts also change the structure of the fouling from a porous structure to a dense cover, trapping the iron chloride and closing it off from the gaseous oxygen thus increasing chlorine corrosion. Pitting is an even more dangerous mechanism of the molten salts reacting as a liquid electrolyte directly with the steel and dissipating it. If the equipment is not protected, costs and lost time can rapidly accumulate when something goes wrong.

When the temperature of the flue gas decreases, a specific gaseous species reach saturation, droplets of the liquid start to condense on solid surfaces. The saturation temperature depends on the load of the concerned species and, for sulfuric acid, on the humidity of the flue gas.

The liquid electrolytes forms wet spots on the surfaces, causing general corrosion and material loss in the form of pitting. In waste-to-energy plants, dew point corrosion is less common than in coal-fired plants, because SO3 reacts with chlorine species, making the formation of sulfuric acid less likely.

William Nixon, IGS Field Operations Director, discusses an urgent case where IGS were required to act fast to help a client get a key asset back online.

The Circulating Fluidized Bed (CFB) Boiler went down on a Friday and the client was liable for a severe penalty if the asset was not back online quickly and within a specific timeframe. Thanks to fast mobilization, IGS were able to apply High Velocity Thermal Coating (HVTS) and help get the CFB boiler back online within four days.

Leave us a note or start a chat with our operator to learn more about what we offer in corrosion and erosion prevention in WtE and Biomass circulating fluidized bed boilers.