In collaboration with one of the world’s largest and most sophisticated O&G refineries in the world, Integrated Global Services (IGS) provided an engineered solution aimed at enhancing the reliability and longevity of its quench columns. This collaboration started with an on-site test application and came to fruition with a fully executed on-site, in-situ project delivery.

In 2007, the client approached IGS to support it in providing a vessel inspection and evaluation of failure mechanisms inside a quench tower. The plant needed to limit weld repairs and metal wastage in the vessel.

The unit consists of four reactors with multiple catalyst beds and inter-stage hydrogen quenches (eight in total). The client was experiencing high metal wastage of >3mm/yr in the quench towers, predominantly due to hydrogen induced corrosion (HIC), causing large areas of pitting and requiring excessive repairs and extended downtime periods.

| Equipment Description | Hydrogen Quench Tower |

| Base metal composition | Carbon Steel |

| Process material phase | Gas / Liquid |

| Process material composition | Heavy Hydrocarbons |

| Outage frequency/cycle | 24-month cycle |

| Wastage Rate (mm/yr) | >3mm |

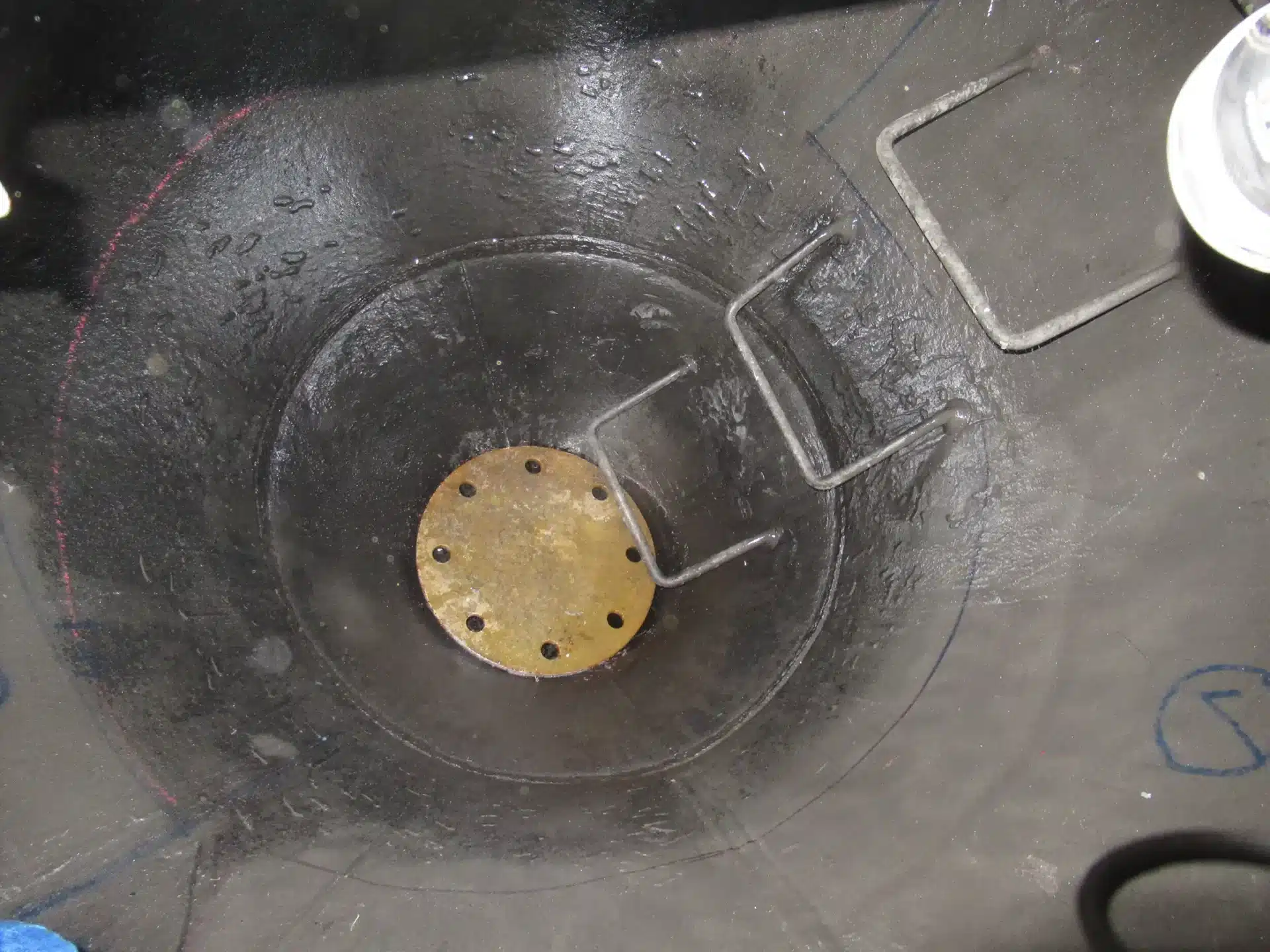

After the inspection and evaluation was conducted, IGS recommended the test application of IGS HVTS cladding on the quench tower.

To support the plant’s maintenance solution considerations, the IGS project team applied 50m2 of HVTS cladding to the quench tower in March 2007. After 10 months, the client inspected the cladding with the IGS team. The cladding was in good condition and no further metal loss of the vessel surface was detected, which resulted in no repairs required in the test area.

The client decided to continue with the application of the IGS HVTS solution on all the quench towers in this unit.

IGS has executed more than a dozen projects in these quench towers since 2008.

Cladding inspection is completed every two years, with ±20% cladding repairs required during the 8-to-10-year period, with no base metal repairs required within the vessels, indicating no metal loss.

In reducing the repairs required in these units, the number of corrosion protection critical path days were reduced from 18 to 5 days – delivering profits estimated at $3.2M due to an increase in production days (earlier start-up) per year.

An additional major benefit for our client was the added motivation to extend from their current two-yearly shutdown to a 4-yearly shutdown cycle.

The successful installation of IGS HVTS cladding on this plant’s quench towers delivered improved reliability together with a sustainable, cost-effective solution, making a significant positive impact on the plant’s operations and showcasing the benefit of utilizing a superior technology, coupled with meticulous planning and quality project execution.

Related Case Studies:

Ethylene Quench Tower Corrosion Mitigation Saves $1.8Mil

Cracker Quench Column Corrosion Stopped with IGS HVTS Cladding

A Short-term Saving has a Long-term Cost!

Column Shell Corrosion Protection Verified

HVTS Prevents Corrosion Attack in a Regenerator Column at LNG Plant

Severe Amine Column Corrosion Permanently Frozen

CATEGORIES: