Pitting corrosion identified inside a process column in an area below the stainless steel cladding.

IGS HVTS alloy cladding was applied to protect the damaged area from further metal wastage.

Asset owner’s external inspection after 2 years in service suggested further internal metal wastage.

IGS proprietary external inspection confirmed the integrity of the internal HVTS corrosion barrier, avoiding an unplanned forced shutdown.

IGS began servicing this middle eastern oil and gas giant’s mission critical equipment in 2013 with an HVTS alloy cladding application on a large de-ethanizer column.

Soon after, came the first applications for this asset owner’s gas plants, where stripper columns (also known as the regenerators) have been protected from aggressive internal pitting corrosion. In 2015, applications at three more gas plants were performed.

Pitting corrosion within these vessels typically appears in similar locations, e.g. below the original stainless steel cladding protection.

Condensation typically occurs only above the trays in the top dome, however, operating conditions can lead to corrosion coming down the column. This leads to metal wastage problems below the clad section, or where the feed comes in from the reboiler.

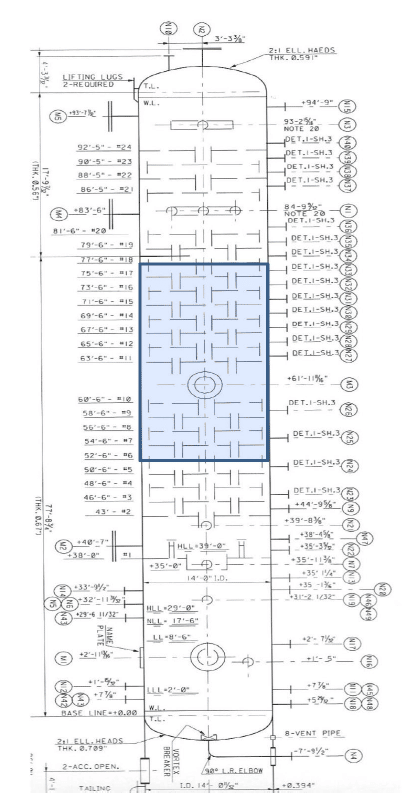

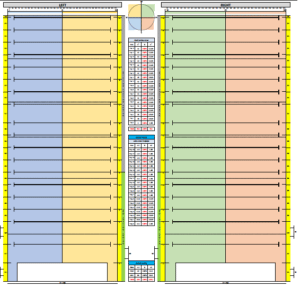

This case study focuses on the HVTS alloy cladding application performed on one of the two trains at this asset owner’s gas plant in 2016. Corrosion in that train (Train 2) was more aggressive than in its companion (Train 1) where the same scope was completed a year before. IGS HVTS was applied on a 140m2 area between trays 6 and 18.

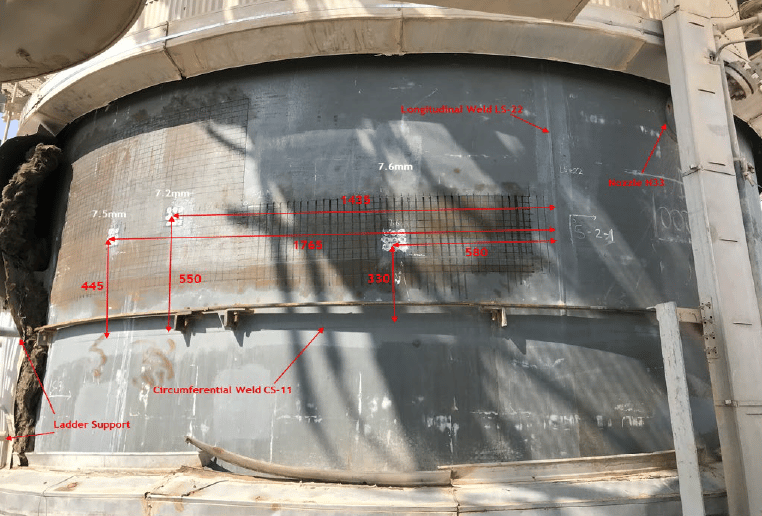

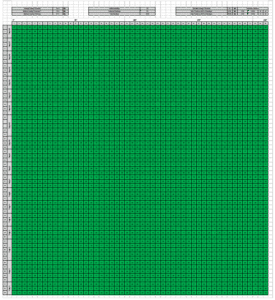

The plant operator continued to perform regular external NDT/UT inspections to monitor the column shell thickness. In 2018, two years after the HVTS application and two years before the next scheduled shutdown in 2020, they started recording readings between trays 15 and 17 that seemed to indicate a loss of shell thickness. An emergency forced shutdown was being considered to allow for an internal inspection to verify the corrosion barrier’s (IGS HVTS cladding) integrity.

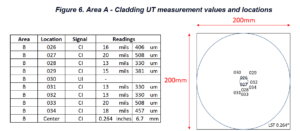

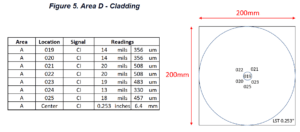

The IGS senior inspection specialist together with the senior materials & corrosion engineer of the asset owner and the gas plant inspector, assessed the HVTS cladding condition using a proprietary inspection technique developed by IGS. This external inspection technique uses a device that has been specifically calibrated so that the inspector can identify not only the shell thickness but also the integrity of the IGS HVTS cladding on the internal vessel surface with advanced waveform analysis.

The plant inspection results were concerning as some wall thickness readings were lower than the recorded minimum thickness’ in 2016. The IGS external inspection confirmed the integrity of the internal HVTS cladding, demonstrating that the lower wall thickness existed prior to the application in 2016 and that no further internal metal wastage had indeed occurred. The shell was still protected.

The internal IGS HVTS cladding integrity was accepted by the asset owner, who cancelled the emergency shutdown, keeping the train in operation. A forced shutdown would have cost millions of dollars, halting production for several days, if not weeks. The column was ultimately opened during a planned shutdown in 2020. The internal inspection results confirmed the findings of the external IGS inspection. The IGS HVTS alloy cladding applied in 2016 has not corroded or worn away, it is still protecting the column from aggressive operating conditions and no further internal metal wastage had occurred.

During the internal inspection of the column it was discovered that the area below Tray 6, which did not have any existing internal protection, was found to be severely corroded requiring urgent mechanical repair to rebuild wall thickness.

After completing the weld repairs, IGS HVTS cladding was applied to the area to further protect the column from internal corrosion, stopping metal wastage in this critical process asset and avoiding future forced outages.

Related Case Studies:

Gas Turbine Corrosion Mitigated by HVTS and Hex Chrome Filtration System

HVTS Prevents Corrosion Attack in a Regenerator Column at LNG Plant

H2S Corrosion in an Upstream Separator Vessel Permanently Stopped

Severe Amine Column Corrosion Permanently Frozen

HVTS Stops Sour Water Stripper Corrosion

Caustic Vessel Protected After Repeated Failure

CATEGORIES:

IGS is here to provide information, answer questions and create an effective solution for your needs.