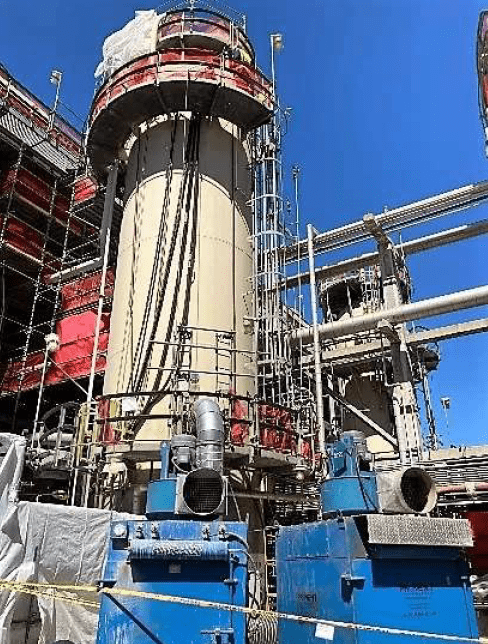

Low pressure separator with minimum corrosion allowance remaining was being prepared for renewable diesel conversion. The plant considered welding an internal cladding, but that option carried significant costs and would require 30 shifts to apply.

The plant selected HVTS, an IGS Solution, to upgrade the metallurgy of the separator to a higher nobility alloy able to prevent carbonic acid corrosion. References, operations excellence and the ability to inspect the separator in between turnarounds without shutting it down were the key drivers for the plant’s decision making.

A multinational Oil & Gas company is sharpening its focus on meeting the world’s growing energy needs while reducing their carbon emissions intensity. As a result, they are converting one of their refineries to a renewable fuels manufacturing and terminal facility that will be able to produce approximately 730 million gallons of renewable fuels per year.

New fuels come with new corrosion risk and the metallurgy of the LP Separator required an upgrade before commissioning.

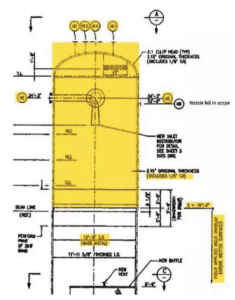

The Plant had weld overlay installed in the bottom of the separator already and were considering welding a higher nobility alloy above that area. Field welding is an expensive and time-consuming process and the plant elected to utilize HVTS alloy cladding that delivered numerous technological and commercial benefits.

IGS delivered an engineering package, including the project plan, method statement, inspection test plan, project safety analysis, risk mitigation plan and the job specific safety data sheets. The whole project was completed in 9 shifts as planned.

Field welding is significantly costlier compared to HVTS and requires 3X the time to apply the solution. This can be a problem if the asset is on the critical path.

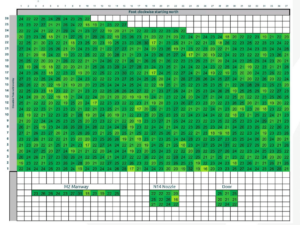

As the separator had a minimum corrosion allowance left, the plant engineers had to be certain that the HVTS will not fail in service. Multiple references and performance qualification performed in the IGS Technology Centre confirmed that HVTS delivers equivalent protection when compared with welding with added benefits:

IGS designed a method to verify HVTS integrity during assets normal operation. This approach offers an extra peace of mind as there is no need to wait until the next scheduled turnaround to ensure that the corrosion protection barrier is intact. The plant welcomed this addition to the service package.

CATEGORIES: