IGS has completed a large number of successful projects within Ammonia Reformers including hot refractory repair to address hot spots without emergency shut down, and applying high emissivity coatings to reduce emissions and generate fuel savings.

The following projects delivered significant benefits to the facility.

Primary Reformer Hot Spot Repair in Ammonia Production Train

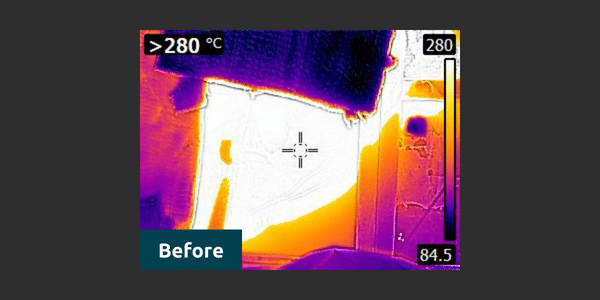

A prominent fertilizer manufacturer based in Qatar has partnered with IGS to prevent an unplanned shutdown of one of their trains. The project focused on addressing the critical issue of hot spots in the reformer duct area of the third ammonia production train.

IGS HVTS Mitigating CO2 Corrosion in Main Amine Column

A major Middle East refinery, in collaboration with Integrated Global Services (IGS), successfully tackled CO2 corrosion challenges in their Main Amine Column, showcasing the efficacy of the High Velocity Thermal Spray (HVTS) technology.

Hot Spot Repair on Ammonia Reformer Saves $Millions by Preventing Emergency Shutdown

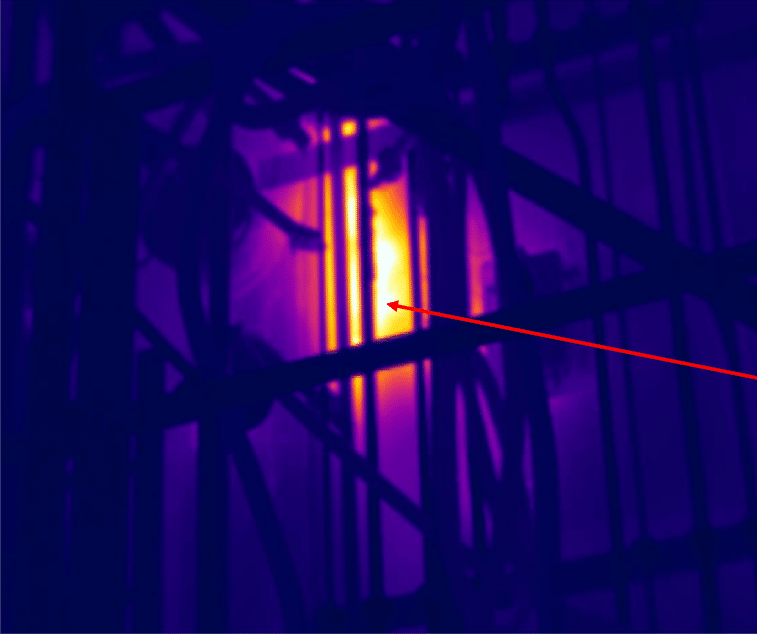

This case study examines an ammonia reformer with a turnaround next planned in three years’ time. A 3 X 1.5m hot spot caused a structural integrity concern. A Hot-tek Hot Refractory Repair on the live furnace saved this plant $5M+.

Ammonia Reformer Hot Spot Repair During Operation

A large U.S. fertilizer manufacturer that was experiencing a “hot spot” on the external steel shell where a manway used to exist. IGS (Integrated Global Services) applied a Hot-tek Hot Refractory Repair solution with no downtime or impact to production – avoiding the emergency shut down usually required to perform conventional repairs.

Primary Ammonia Reformer Excessive Fuel and Emissions

Primary ammonia reformer was consuming too much fuel and in need of reducing emissions. Left as is, the heater would have continued to waste fuel and purchase extra CO2 credits amounting to millions of dollars over two turnarounds.

IGS applied Cetek high emissivity coating improving the radiant heat transfer efficiency and decreasing fuel firing and bridgewall temperature.

Refractory Coating Achieves 4% Fuel Savings For An Ammonia Reformer

Cetek evaluated the ammonia reformer and projected fuel savings of 4% following the application of the ceramic refractory coating. Fuel savings of 360GJ/day (4%) were delivered as projected, while the bridgewall temperature was reduced by 50°C / 90°F.

Ammonia Reformer Hot Spot Repair During Operation

IGS (Integrated Global Services) applied a Hot-tek Hot Refractory Repair solution to a large U.S. fertilizer manufacturer that was experiencing a “hot spot” on the external steel shell where a manway used to exist.

We applied our solution with no downtime or impact to production, avoiding any emergency shut down usually needed to perform conventional repairs.