Syngas reformer with the next turnaround planned in three years’ time discovered a 3 x 1.5m hot spot causing a structural integrity concern. Steam quenching/steam sparging cannot be a sustainable solution with a hot spot that large. Our Hot-tek Hot Refractory Repair on the live furnace saved this plant more than 5M US Dollars.

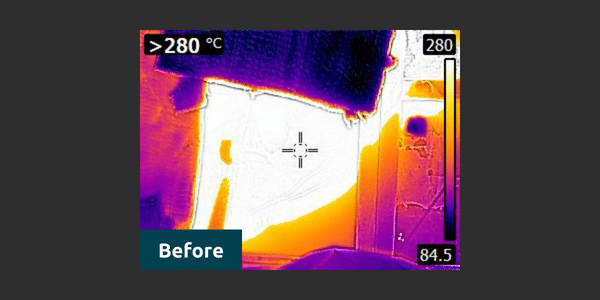

The Plant’s ammonia reformer had a hot spot over a large area (3 x 1.5m). The surface integrity of the shell had deteriorated over a period of approximately 18 months due to long-term exposure to high temperatures, leading to steel deformation. Despite the use of steam quenching, the temperatures were rising progressively threatening the integrity of the shell. The next planned turnaround was in three years’ time. Shutting down the unit for an emergency repair would have had a major cost impact due to loss of production.

Steam quenching or steam sparging means cooling of the overheated heater shell by steam. This allows to keep the shell from failing completely until repair is possible.

As steam quenching can’t be considered a sustainable solution, the plant approached IGS to perform Hot Refractory Repair, a proprietary patented IGS Hot-tek solution to address hot spots on a live furnace during its normal operation.

Performing the hot spot repair during the units normal operation saved the plant over $5 million by avoiding an emergency shutdown. A conventional repair would have required the unit to be shutdown for at least three days.

CATEGORIES: