IGS has completed a large number of successful projects within Crude Oil Heaters including eliminating fouling for more efficient operation, and emergency tube support installation to prevent hot spots.

The following projects delivered significant benefits to the facility.

Increasing Furnace Efficiency With Hot Convection Cleaning

Crude Heater with significant process preheat was overfiring. Convection tubes were fouled leading to High Bridgewall and High Stack temperatures.

IGS performed Hot-Tek cleaning through existing access doors on an existing platform.

Emergency Tube Support Installation during Operation

An unusual maintenance application was performed on a crude oil unit, while it was still in operation, at a refinery in Sweden. This refinery is not only among the most modern and energy efficient ones in Sweden, but is also Scandinavia’s largest plant with the capacity to refine 11.4 million tonnes of crude oil per year.

With their Hot-Tek offering, Cetek has a lot of experience in different types of maintenance work on assets while they are still in operation.

A solution to this problem was developed in collaboration – the new support was designed and purchased prior to insertion.

Rapid Maintenance during Crude Heater Operation

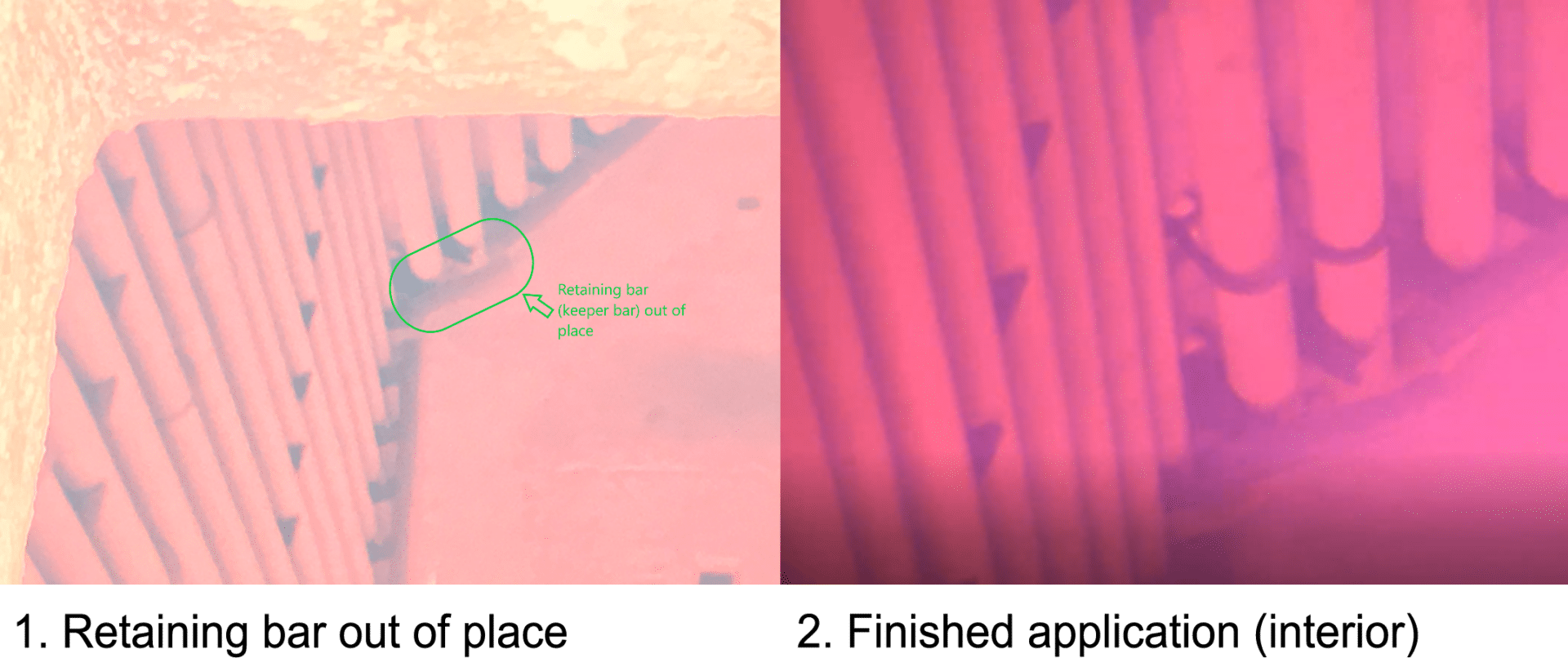

Two tubes in a crude heater have partially lost their tube support. The retaining bar fell out of place.

In order to prevent a potential unplanned shutdown in the future, IGS Hot-tek delivered a turnkey solution, installing tube stabilizers while the heater continued normal operation.

Tube Tech Restores Offshore Crude Oil Heaters

The operator of one of the largest offshore projects in the North Sea required an effective heat transfer efficiency restoration solution for two of their crude oil heaters ready for inspection.

A significant difference in the level of fouling on both heaters meant the contractor had to be prepared for two very different projects.

Having worked with Tube Tech in the past the operator felt we were the ideal choice for this project due to our innovative methodology, immediate response service, offshore-trained technicians, and first-class communication systems.