TubeTech™ Restores Offshore Crude Oil Heaters

Introduction

The operator of one of the largest offshore projects in the North Sea required an effective heat transfer efficiency restoration solution for two of their crude oil heaters ready for inspection.

A significant difference in the level of fouling on both heaters meant the contractor had to be prepared for two very different projects.

Having worked with TubeTech™ in the past the operator felt we were the ideal choice for this project due to our innovative methodology, immediate response service, offshore-trained technicians, and first-class communication systems.

The Challenge

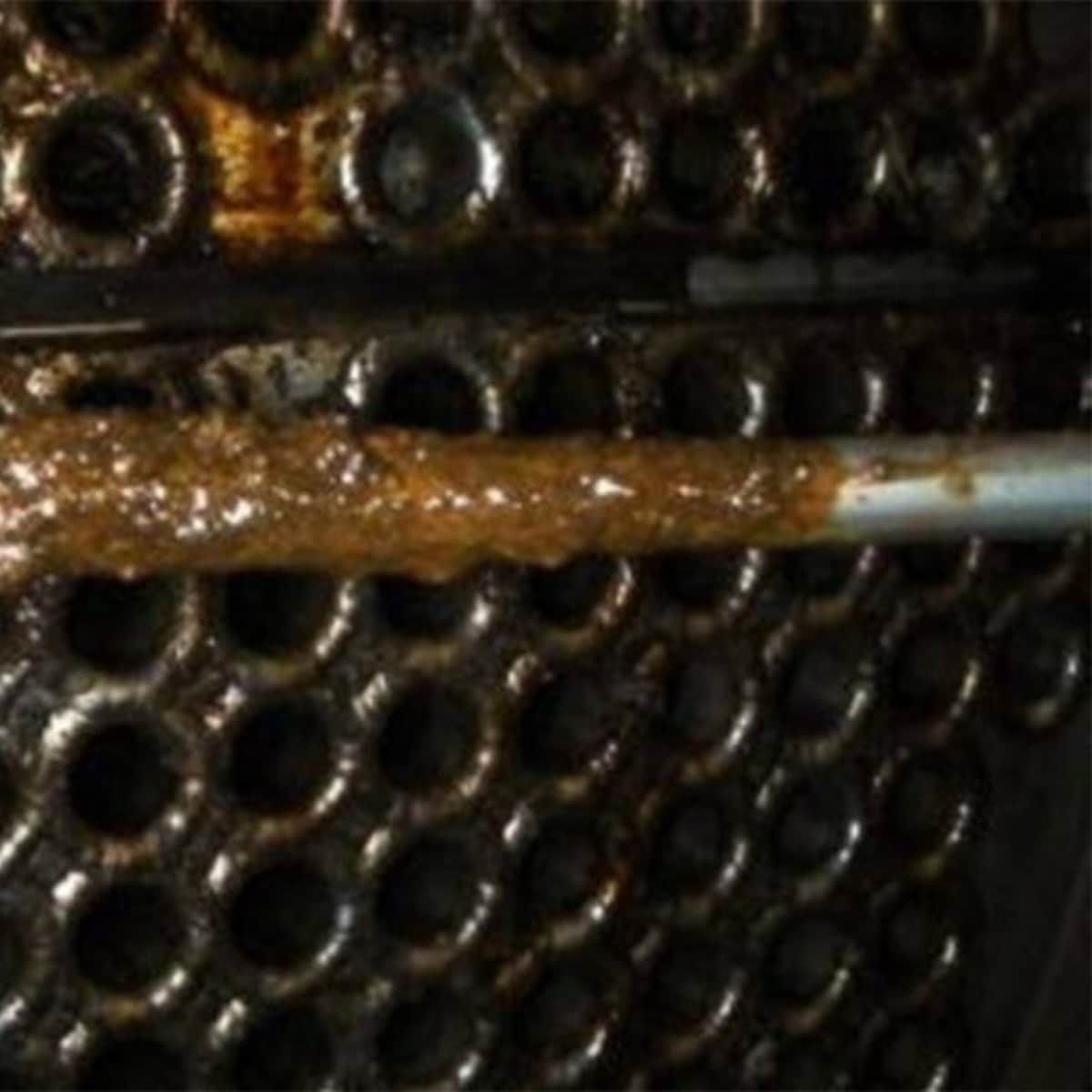

- Both crude oil heaters were fouled with a gooey consistency deposit believed to contain sand and other organic content.

- Crude Oil Heater ‘A’ was the least fouled. The deposit was believed to be no more than 0.2mm and the heater was running with no issues.

- Crude Oil Heater ‘B’ had shown a concerning rise in pressure drop across the unit, so it was deemed unserviceable and was forced offline. The fouling within this heater was expected to be significant.

- Both crude oil heaters had been cleaned using traditional water jetting techniques a few years previous, but due to the limitations of traditional methods, some scale had been left on the tubes.

- The platform operator had tried a chemical flush to improve the pressure drop on heater ‘B’, but this was unsuccessful, possibly due to severe blockages within the tubes.

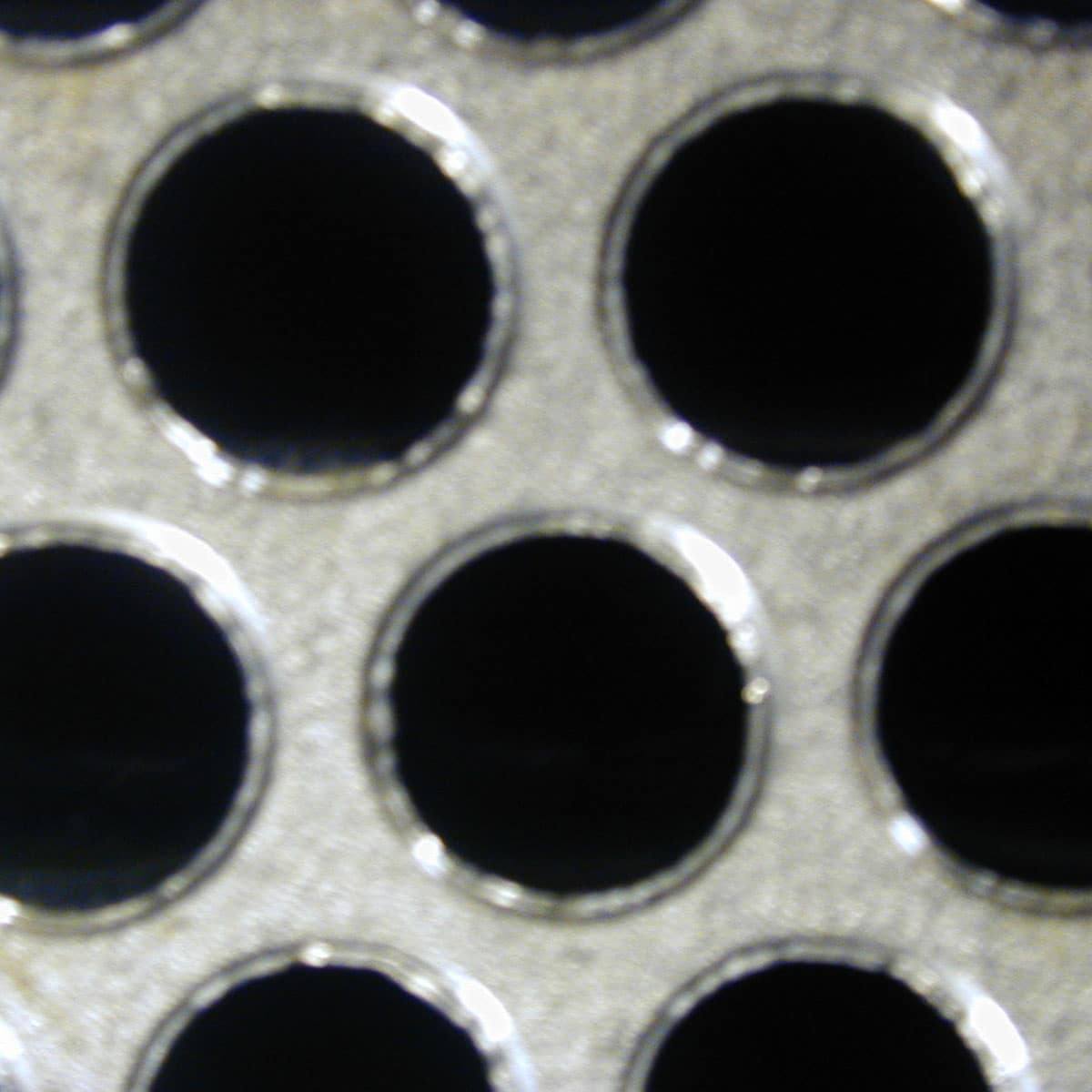

- Both units required inspection and restoration to a suitable IRIS standard.

The Solution

- As with all offshore contracts, effective preparation was paramount and with two different levels of fouling to deal with TubeTech™ arrived on the platform with a selection of innovative technologies to deal with a range of scenarios. A team of technicians were also deployed to work day and night shifts.

- TubeTech™ lined the entire bundle area with plastic and a waste collection divert was also erected in the bundle area.

- Crude oil heater ‘A’ was restored first as it had the least fouling and needed to have an IRIS inspection immediately after fouling had been removed.

- Super high-pressure water jetting using a combination of turbojet & polishing jets was used to restore heater ‘A’ quickly. After this, the IRIS inspection was completed successfully.

- Crude oil heater ‘B’ was initially restored using the same system as the ‘A’ unit, once all the blockages were removed (100% of the tubes) a thin hard scale was left even harder than originally thought.

- TubeTech™ converted its bespoke pumps to facilitate considerably higher pressures, attached a rotating wysper seal lance and was then able to achieve the desired standard suitable for IRIS inspection to prove that the tubes were still in good order and in suitable working condition.

Client comment:

“Very good safety culture and professional approach. Technicians always on time and very professional – a credit to TubeTech™.”

Reduce Downtime and Maximize Profitability

IGS is here to provide information, answer questions and create an effective solution for your needs.