Newsroom - Oct 15, 2020

IGS Middle East Team Delivers Two Critical Projects During the Pandemic!

IGS executed two essential maintenance projects in the Middle East during September, amidst peak COVID-19 restrictions in the region.

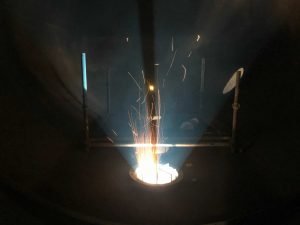

HVTS Cladding for Oilfield Equipment in Oman

In Oman, IGS executed the internal HVTS cladding of a flow-splitter: oilfield equipment critical for hydrocarbon production, and crucial for the economy. Through the Oil Company’s direct support, special permission was obtained for the entry of IGS crews into Oman for project execution. Standard governmental regulations only permitted Oman residents and Omani nationals to enter Oman during this period.

Once on site, IGS crews were faced with an outbreak of COVID-19 in the vicinity of the IGS project location. IGS crews followed strict COVID-19 safety protocols and completed the project safely and ahead of schedule to the client’s great satisfaction.

HVTS Project Executed in Qatar

Another project was flawlessly executed during the month of September in Qatar. The client, a major gas processing company in Qatar, arranged flights and exceptional visas, enabling entry into an international travel restricted country. The client also supported IGS with hotel arrangements, where IGS crews endured 14 days of quarantine before mobilization and execution of the project.

Dennis Snijders, Sr. Regional Director – Middle East, has commented: “Hats off to our clients in the Middle East, who made entry possible despite COVID-19 restrictions and, of course, hats off to our IGS crews who successfully and safely executed these projects! These two projects are a testimony of the collaborative relationship we have with our clients, the importance of the specialized services that IGS provides to asset owners, and the ability and commitment of IGS operations to the safe execution at the highest quality standards.”

Maintenance Project Execution in 2020

In 2020, IGS is set to complete at least 273 projects, keeping essential infrastructure going by preventing corrosion, erosion, and fouling within Coal Power/WtE & Biomass Plants, Refineries, Chemical Producers, Pulp & Paper, Mining/Metals, Cement Plants, and other facilities.

IGS Covid-19 Response

In these unprecedented times, delivering specialized services for mission-critical equipment in the energy sector is a challenge. To this, we say – Challenge Accepted! For IGS, it is essential to keep delivering the quality of services that our clients around the world expect from us so they, in turn, can continue to provide critically important services to the world.

IGS teams are stationed in multiple strategic locations around the world to enable the swift mobilization of our crews to any job site anywhere and at any time. From maintaining critical infrastructure in Poland to ensuring the reliability of petrochemical complexes in the Middle East, all while completing colossal projects in Japan, Indonesia, France, and the USA, IGS has never stopped delivering projects across the globe.

Every day, our dedicated local teams continue to perform safely and efficiently in these challenging conditions. IGS’s top priority remains the health and safety of our people and the customer’s personnel. All while ensuring the reliability of the most critical energy and chemical producers to facilitate the continuity of essential services in these challenging times.

Going Digital: Continuing Education and Information Sharing during the Pandemic

IGS continues sharing best practices, information, and general education through webinars, white papers, and videos, by collaborating with prominent industry associations, including NACE, Refining Community, Euro Petroleum Consultants, and AmmoniaKnowHow, among others.

For the latest news and updates, follow IGS on Linkedin.