Green Bay Packaging was started in 1933. It has two pulp and paper mills, one

in Morrilton, Arkansas, and another in Green Bay, Wisconsin. A new paper mill was also built and started up in Green Bay in March 2021, taking the place of the 71-year-old mill nearby.

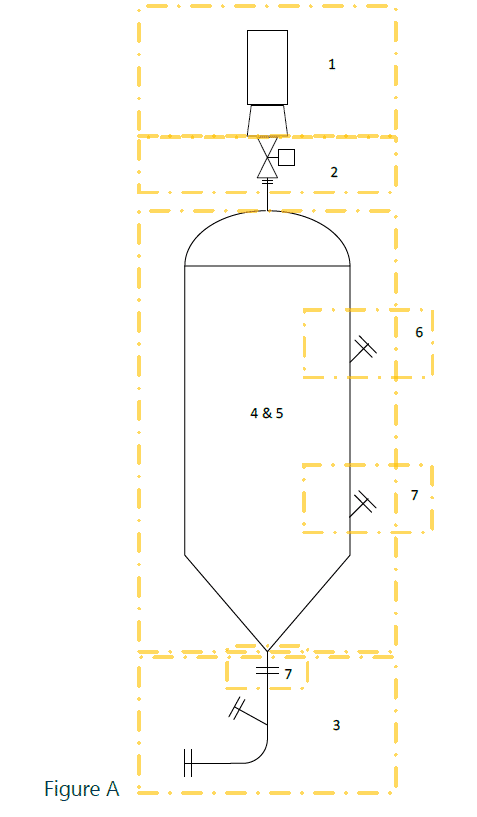

A combination of corrosion and erosion occurred in a batch digester environment. Corrosion is observed in the entirety of the vessel. The lower cone experiences additional erosion.

Integrated Global Services (IGS) has been working at the Green Bay Morrilton mill since 2010, first installing a sample coating patch in the recovery boiler and then in 2012 taking over protection of the five batch digesters at the mill.

The plant became dissatisfied with their previous thermal spray vendor due to their erratice price increases and their lack of transparency. After visiting IGS projects at other pulp mills, Green Bay invited IGS to take over their corrosion protection initiatives at the Morrilton Mill, establishing a successful partnership.

In addition to the coating applications on the ID of each batch digester, IGS has performed welding and grinding work to include nozzle replacements and bore weld overlay with Inconel 625 on the ID of nozzles. Also, as part of the scope requirement, IGS provides our own scaffolding on the ID of each batch digester.

The feedback on the performance of IGS has been excellent after every annual outage. No replacement of the dome, shell, and cone has been required.

DIGESTER PROTECTION

IGS’s High Velocity Thermal Spray (HVTS) and DiArc solutions upgrade existing metallurgy to higher alloys that provide a barrier to mitigate corrosion and / or erosion in mission critical equipment around the world. IGS has performed over 4,000 site projects and installed millions of square feet of reliable metal cladding surface protection.

Five (5) batch digesters are being protected

Application takes ~six (6) days per digester to complete

Each digester is inspected every 12 months

Annual reapplication takes ~30 days in all five (5) digesters

IGS is protecting Green Bay digesters for over a decade

No replacement of the dome, shell, and cone has been required

The Morrilton Mill takes one digester down at a time for IGS to work on, leaving the other four digesters in operation to support the mill production requirements.

This work is not done during the normal mill outage but it iscompleted during the first quarter each year while the mill is in operation.

Including the set up, tear down, and movement between digesters, IGS normally spends between 25 and 35 days on site, approximately 5-7 days per digester.

The feedback on the performance of IGS has been excellent after every annual outage.

CATEGORIES: