Newsroom - Oct 31, 2024

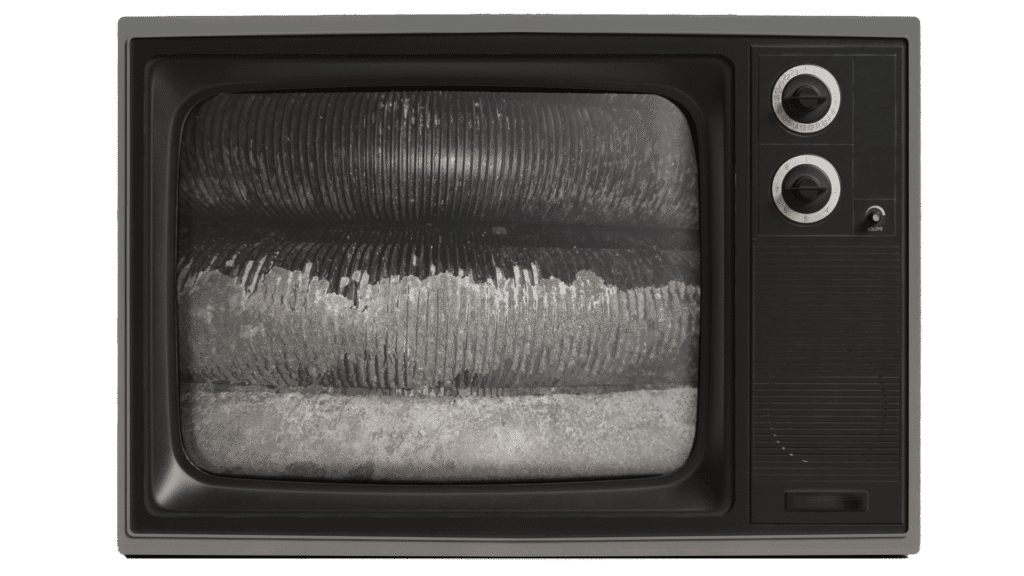

The Scariest Outcomes of Convection Section Fouling

Convection section fouling in fired heaters and furnaces can lead to significant operational challenges. Here are the four key scary outcomes associated with convection section fouling.

1. Decreased Efficiency

Fouling in the convection section reduces heat transfer efficiency. As deposits accumulate, they insulate heat transfer surfaces, forcing your system to work harder to maintain temperatures. This inefficiency can lead to increased energy costs or reduced capacity.

2. Increased Risk of Tube Failure

The buildup of deposits can create thermal stress and overheating in critical components, leading to premature tube failure.

3. Safety Hazards

Fouling can create safety risks, such as blocked airflow and overheating. These conditions can compromise the safety of your operations and personnel.

4. Higher Emissions

Increased energy use leads to greater emissions from your system. This not only affects environmental compliance but can also result in fines and damage to your facility’s reputation.

The Solution: IGS’s Convection Section Cleaning Rover

IGS offers a solution to these challenges with our Convection Section Cleaning Rover. This advanced technology effectively removes over 90% of fouling deposits without extensive downtime or manual intervention. The next-generation Mark 7 rover features a patented wheel system and a baffle and traverse system that allow it to crawl over intermediate tube support plates and across tubes, requiring fewer access points and enhancing its ability to access hard-to-reach areas. The rover also employs lidar technology for distance sensing and provides live HD footage for real-time feedback on the condition of the convection bank.

Case Study

See how Borealis, an ethylene plant, achieved great efficiency with the IGS Tube Tech rover. Read the case study.