Newsroom - Jul 15, 2022

Maximize your profits from Coal Boilers with Big Blue Air Cannons!

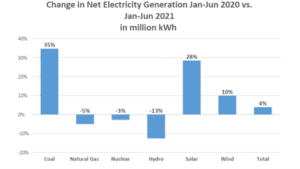

A long-standing trend has commonly been followed in the field of power generation. Many plants have focused on reducing the usage of coal in favor of natural gas. Two primary reasons have been the key factors for this trend for quite some time: natural gas is less expensive, and it offers a better environmental footprint than coal.

So why are plants now transitioning away from natural gas?

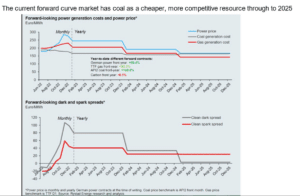

The recent increase in the price of natural gas, especially in the United States, is driving this movement back to coal and other power sources such as solar and wind. A source from Southern Company recently reported that the cost of burning natural gas in generation of power has risen by 200%, while the generation cost from coal has risen by only 40%.

This differential has made it more profitable for utility companies to make the shift to coal. In addition, reports indicate that power is selling at thirty times more than the cost of coal. Based on the hot summer and an increase in power requirements, this has led to tens of millions of dollars in profits for power plants.

It has become abundantly clear that the recent trend, due to higher gas prices and climate changes, is fixated on using coal to generate as much power as possible. This coal-powered approach does not exist without its own challenges, though. The coal supply and regulations on the environment present difficult barriers to overcome. Instead of being base-loaded, most coal-fired boilers have been forced to run at reduced loads. Running these boilers at decreased rates produces challenges for their SCRs to operate effectively and reduce NOx. Diminished loads often lead to fly ash fall-out in dust work and reduce the efficiency of the SCR. The current cleaning devices on the SCRs are not designed to eliminate the buildup caused by the decreased loads.

Tighter regulations leaves less margin for error

In the past, most SCRs could meet NOx emissions even with buildup. Recently, though, due to stronger regulations and increased buildup, this is likely no longer the case. To achieve as much NOx removal as possible, it is critical to keep the SCR clean and maximize the entire catalyst surface area. In general terms, if a mere 10% of the surface area is covered with ash, a loss of up to 10% NOx emission reduction can be expected.

The new environmental regulations allow for the acquisition of NOx credits. These credits are extremely valuable in high-demand situations where the plant may need to exceed NOx emission levels. The current regulation penalties can be stifling if the NOx limits are exceeded, but due to the huge increase in natural gas prices, plants can afford to pay the penalties and still generate profits. With NOx credits and the overall improvement in efficiency of the SCR, these profits can be even more lucrative. In most cases, the return on investment after the cost of installation is estimated to be less than one month.

Current predictions maintain that coal will be the most price-competitive solution to the generation of power through 2025.

It is imperative for plants to find methods to fine tune their SCRs and maximize the amount of power generated by these coal-fired boilers. A recent inspection that was conducted on a power plant’s SCR indicated massive buildup, costing the plant thousands of dollars to manually vacuum. The severity of the buildup forced the plant to take downtime during the recent high- demand time with record power prices. This forced outage has costed the plant millions of dollars in lost revenue. Downtime for a plant is difficult to manage at any time of the year, but it will be even worse if it extends into July or August.

What’s the Solution?

The problems encountered at this plant have proven solutions, though, and a return on investment is expected in as little as one week. The combined force of Cormetech and IGS is spearheading this solution. The key is keeping the catalyst surface area open so that NOx emission reduction can be made possible. The installation of the IGS Big Blue Air Cannon and CatFlow Screen will eliminate the fly ash buildup and allow greater NOx emissions, which has a direct link to power plants being able to generate greater profits.

Due to poor coal supply and environmental regulations, it is expected the load swings on coal- fired boilers will not be eliminated altogether. However, when the demand for power is at its greatest and the selling price is at its highest, plants must be able to take advantage of this. When power can be sold at thirty times the operation cost, the price of cleaning equipment becomes relatively miniscule in comparison in order for the plant to run efficiently and effectively.

Read More: IGS Environmental Cleaning Solutions