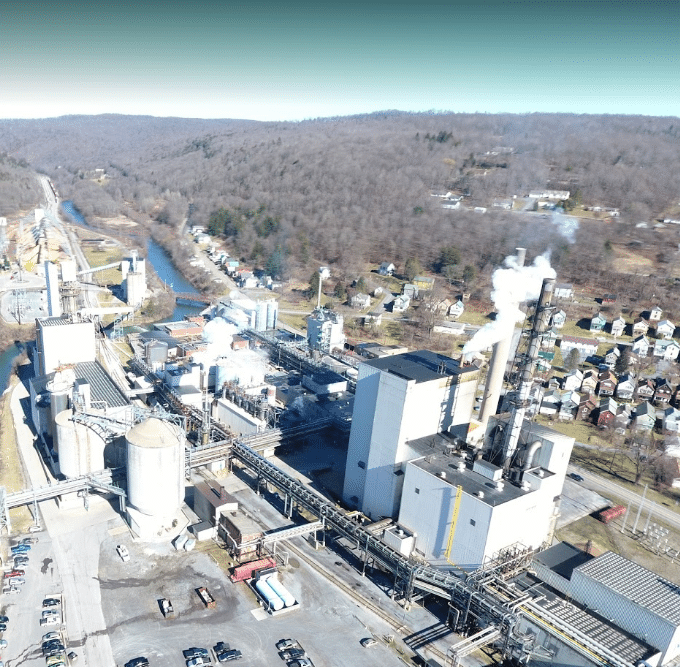

Recognized as one of the most technologically advanced paper mills globally, this Pennsylvania, US, mill boasts a long and rich history of papermaking since 1888.

After changing the way they operated the boiler, the mill started to see corrosion within a 2 to 3 ft band area just above the lower furnace’s composite tubes. The mill has been scaffolding to repair thickness loss with W/O pad welds with 18-month outage cycles. Exact wastage was typically 8 to 14 mils per year.

The mill was looking for a lasting solution, and they got it. IGS SMARTGard® solution uses HVTS alloy cladding offering 2-3 times longer service than typical thermal spray coatings due to its low porosity and the absence of oxides.

Inspection at every shutdown verified IGS HVTS cladding integrity. Where necessary, small remedial work was performed to maintain corrosion protection. Pad welding was no longer required, and IGS HVTS caldding has been applied to additional areas suffering corrosion damage.

CATEGORIES: