Newsroom - Sep 8, 2021

Boiler Cladding: Cutting Corners is no Longer the Norm!

When power boilers are experiencing erosion, corrosion or fouling, boiler operators rely on thermal spray and weld overlay companies to consistently solve these problems ensuring boiler’s lasting reliability.

How Can Tube Leaks be Avoided?

Tube leaks can cause the plant to drop 25% in its baseline profitability. Such losses are unacceptable to the operator. So how can tube leaks be avoided? Applying quality protection and continuously monitoring it is the only way to ensure reliability and anticipate future maintenance intervals and scope.

What about Quality Control?

Boiler operators are typically not permitted to enter the boiler while thermal spray or weld overlay work is taking place. Quality control can therefore only be performed after the protection is applied. In terms of thermal spray, accurate quality control is difficult to achieve as only the densifier may be visible, disguising the condition of the underlying cladding system.

Furthermore, visual inspection is not enough to predict wear rates over time. A comprehensive cladding map that can be verified and updated year on year is the only true indicator of the cladding performance. You can not manage what you can not measure!

Not All Thermal Spray Companies are Created Equal

Some vendors do not abide by these principles. As a result, market dominance over time has caused a decline in quality and accountability. Not all thermal spray companies, however, are created equal. Integrated Global Services (IGS Europe) recently had an opportunity to correct the subpar legacy left by a previous thermal spray vendor servicing two boilers in the Czech Republic.

Petr Duroska, IGS Boiler Reliability Expert, who oversaw two HVTS applications, said: “The operators of these two CFB Boilers became dissatisfied with their thermal spray vendor making claims they could not substantiate. This caused the plant management to contact IGS.”

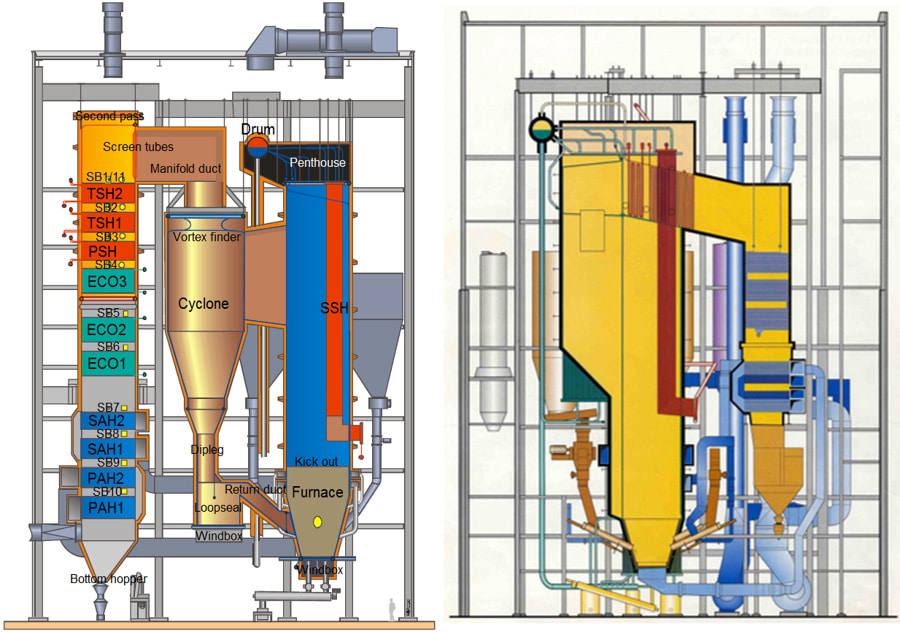

Two CFB Boilers

The boilers are circulating fluidized bed coal-fueled boilers manufactured by SHI Foster Wheeler and Valmet. With 141 and 90 megawatt thermal output respectively and the superheat temperature of 533°C, they burn lignite and hard coal.

Czech District Heating Power Plant Boiler

One of the boilers, within a Czech district heating power plant, was being serviced by a thermal spray vendor until 2015. Petr said: “They felt cheated. The vendor claimed to be measuring cladded areas but didn’t actually do so.”

During the next outage, IGS Europe selected three different alloys for testing within the boiler to determine the most optimum lasting protection, including SNCR openings and superheater elbows. IGS 8000 series alloy has ultimately been selected as most suitable and has since been applied both onto uncoated surfaces and over existing alloy deposited by the previous vendor. Year by year, IGS Europe were able to measure and monitor the performance of the cladding, extending the scope and replacing or refurbishing previously applied cladding.

Fertilizer Plant Boiler

Commissioned in 2015, this boiler was being serviced by the same commodity thermal spray vendor from the very beginning. Petr said: “Similar to the previous case study; the operator was not satisfied with their vendor as they never presented post job reports and measurements. In addition, the vendor only offered a 12-month warranty, then would come every year to maintain the cladding with little justification at a full cost.”

Free Consultation with IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.

IGS Solution

Application Complication

The densifier can work as a wear indicator and prevent some slagging where necessary, but it is not a substitute for an alloy cladding.

Image: Cladding thickness reading after densifier removal.

Spalling, Chipping and Cracking

Petr said: “When we started to blast it, we removed the densifier and what we found underneath was just a very thin layer of the original cladding. And what was even worse, it was spalling, chipping and cracking. We had to remove the majority of it completely. Luckily, it didn’t cause any delay during the shutdown. Our team had to work harder and managed to restore the cladding around the kickout area.”

CFB Best Practices

Another subpar legacy left by the previous vendor was the fact that the cladding was not applied in accordance with established best practices for CFB environments. “They were literally cutting corners there.”, added Petr.

Lessons Learned

The lesson learned from these case studies is that you cannot manage what you cannot measure. Large companies with a seemingly good reputation can seem honest and professional, but the quality may vary project by project. Companies that specialize in a variety of workshop and field work may be tempted to recruit subcontractors without spending time on due diligence and quality control. This practice of cutting corners, which ultimately harms boiler operators, should not continue. There needs to be greater awareness of reasonable expectations from the thermal spray vendors, and IGS is determined to bring transparency to the process, ensuring boiler reliability, increased uptimes, and ultimately, enhanced power plant profitability.