With over 25 years of applications around the world in Pulverized Coal (PC) Fired boilers, IGS has developed proven solutions to extend the life of boiler tubes providing a reliable, long-term solution with significant cost and time savings to its customers. The IGS HVTS cladding has been recognized as the gold standard to resist fireside corrosion in high-temperature sulfidation environments. As only one example, IGS HVTS was proven the best product in some of the most intense conditions in a 39,000 hour test in a 1,300 MW supercritical boiler by EPRI, Electric Power Research Institute.

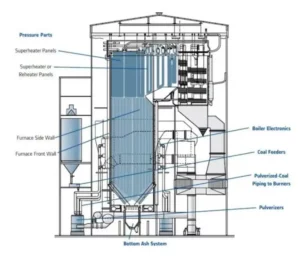

PC-Fired Boilers generate thermal energy by burning pulverized coal that is blown by a combustion air stream to the burners in the firebox. These coal burners are typically located on the front and rear walls or in each of the corners to be known as wall fired or corner fired burners, respectively. There are various types of coal, from anthracite with its high carbon content to bituminous coal, subbituminous coal and lignite (brown coal) and each of these coal types have varying characteristics.

The two primary characteristics that affect PC-Fired boilers, are the thermal efficiency (BTU/lb) of the coal and the sulfur content. As the combustion takes place, Sulfur and other compounds from the coal react with the surrounding water walls iron-based materials. This reaction causes fireside corrosion. This metal wastage typically occurs in the lower furnace all the way up to the mix zone.

In the past decade, there has been a heavy focus on reducing environmental emissions. In order to reduce the production of NOx during the combustion, low-NOx retrofit burners are used in the boiler. These burners reduce the production of NOx by slowing down the combustion, lowering in this way the temperature of the combustion and taking the combustion away from the burners higher up into the furnace. This is achieved by reducing the amount of oxygen in the area where the burners are (lower portion of the furnace) and injecting that oxygen higher up in the furnace using over-fire air ports. Low-NOx retrofit causes areas lower in the furnace to be oxygen starved or under reducing conditions (or in most severe cases, cycling between both).

Although the whole corrosion process is far more complex, it can be summarized as follows: in normal combustion with the presence of correct amount of oxygen (before low-NOx burners), the sulfur present in the fuel will combine with oxygen and remain in gaseous condition and exit the stack. In a combustion under reducing conditions (low oxygen), the sulfur will combine with hydrogen and deposit on the tube surface reacting with the iron of the tube material to form a scale of FeS, and repeat the cycle as more H2S deposits on the walls, causing significant tube thinning.

IGS addresses this and other problems specific to coal fired furnaces, such as the build-up of ash or slag on the furnace walls leading to changes in temperature and emissivity, which ultimately affect the performance of the furnace. Most of this build up occurs in the superheat section and on the waterwalls.

Boiler corrosion, erosion or metal loss can be prevented by changing the boiler’s operating conditions and protecting the tube surface from the combustion environment. IGS’ High Velocity Thermal Spray (HVTS) cladding can serve as a protective barrier eliminating further wastage.

For PC-Fired Boilers, IGS applies high alloy materials to produce a homogenous (particles typically <50um) coating. The coating displays ultra low permeability to corrosive media that optimizes its performance in Coal Boilers.

IGS High Velocity Thermal Sprayed (HVTS) cladding is ideal for long-term, reliable protection from the above described typical wastage mechanisms. We designed the cladding composition in the mid-2000’s specifically for high temperature sulfidation environments with the understanding that permeation and oxide content should be below critical specified levels for long term cladding performance.

Our HVTS is a High Velocity, low stress state, thermal sprayed Metalspray® specifically suited for boiler tube protection in combustion environments with aggressive sulfidation conditions up to 1800°F (980°C). It is highly protective against under deposit corrosion, when Sulfur together with Sodium, Potassium and Vanadium Oxides form low melting temperature pyro-eutectic salts. The high Chromium content, together with performance enhancing elements provide a dense stable coating, with high bond strength due to micro-fusion sites on the substrate. A thermal expansion coefficient at the midpoint between carbon and stainless steels makes it well suited to both as substrate materials. The material also has good erosion resistance due to effective hard-phase integration.

IGS HVTS was also tested by world renowned EPRI, Electric Power Research Institute, in a 1,300MW high sulfur coal, Supercritical boiler. Several other competitor’s materials were also tested, and IGS HVTS was the ONLY material to fully protect the substrate from corrosion during the 39,000 hour testing period.

We exclusively utilize true High Velocity application process, where atomization of the material occurs before or in a super-sonic gas stream. It is the only way in which to achieve such optimal cladding properties needed for reliable and predictable long-term cladding performance. We offer our customers the following advantages over other thermal spray and cladding solutions:

Fill the form below or contact one of our global locations to prevent expensive mechanical repair of your boiler.

IGS is here to provide information, answer questions and create an effective solution for your needs.