In 2010, IGS installed an LPA screen system in each of the four 700MW boilers in a pulverized coal-fired power plant in southeast US to protect the newly installed SCR from LPA, commonly known as popcorn ash. If allowed to reach the SCR, LPA causes severe ash piling and catalyst damage, something personnel at the plant were concerned about.

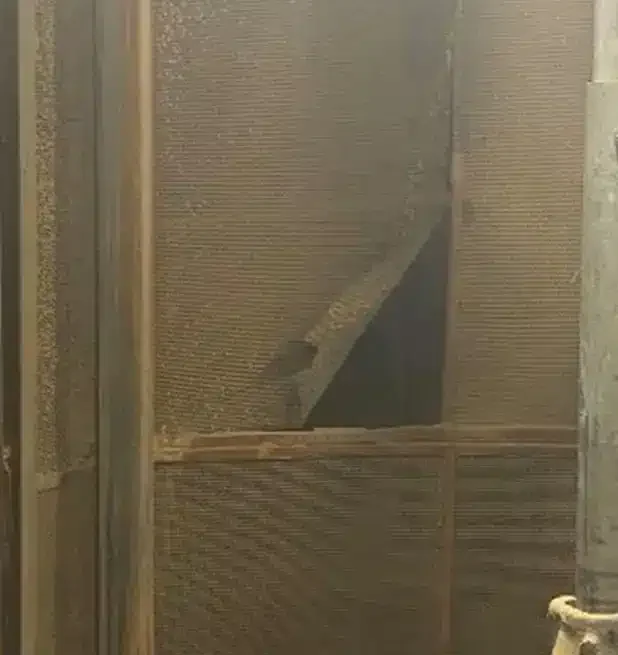

The facility chose to invest in a high-quality, long-lasting, and reliable NoNOx LPA screen system to protect the SCR. Other than regular inspections, very little maintenance was required for the first six years of operation. However, similar to high-performance brake pads on a heavy-duty truck, even the best LPA screens wear over time and eventually require routine maintenance and replacement. Screen breaches (as shown in the image) aren’t uncommon but can be costly.

Understanding the importance of keeping the SCR free from LPA, this plant adopted a proactive maintenance approach. This involved regular detailed inspections of the system and documentation of wear patterns found on the screen. If a screen panel was found to have significant erosion (shown in the image), it was replaced with spare panels held onsite prior to screen failure, eliminating the risk of LPA screen breaches between outages.

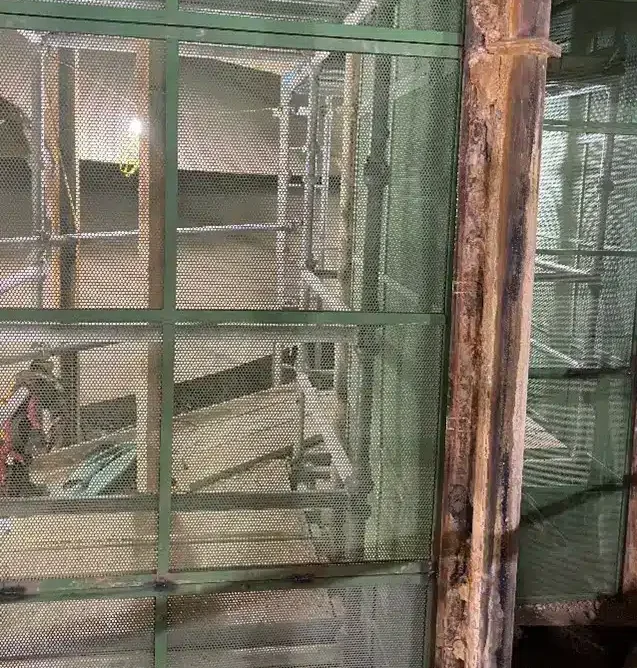

By 2022, the LPA screen system had reached the end of its expected service life. Although the panels were in relatively good shape for their age, the plant decided to fully replace the LPA screen panel array, to ensure reliable LPA filtration for years to come. The plant also decided to upgrade the system to the two-stage LPA screen coating, which offers better erosion protection and a green visual wear indicator. This visual wear indicator dramatically reduces inspection time while allow improving inspection accuracy.

The exceptional maintenance practices implemented by the plant resulted in hassle-free LPA screen operation and complete protection of the SCR from LPA and related ash build-up. By performing regular inspections and utilizing a proactive maintenance approach, this plant was able to prevent LPA screen breaches and minimize unplanned maintenance costs. Additionally, the two-stage coating upgrade will help them perform more efficient inspections and identify high-wear regions more accurately. Ultimately, this resulted in reliable and efficient SCR operation and accurate annual budgeting of operating costs, saving the plant from unforeseen operational and planning headaches.

Related Case Studies:

Related Questions:

CATEGORIES: