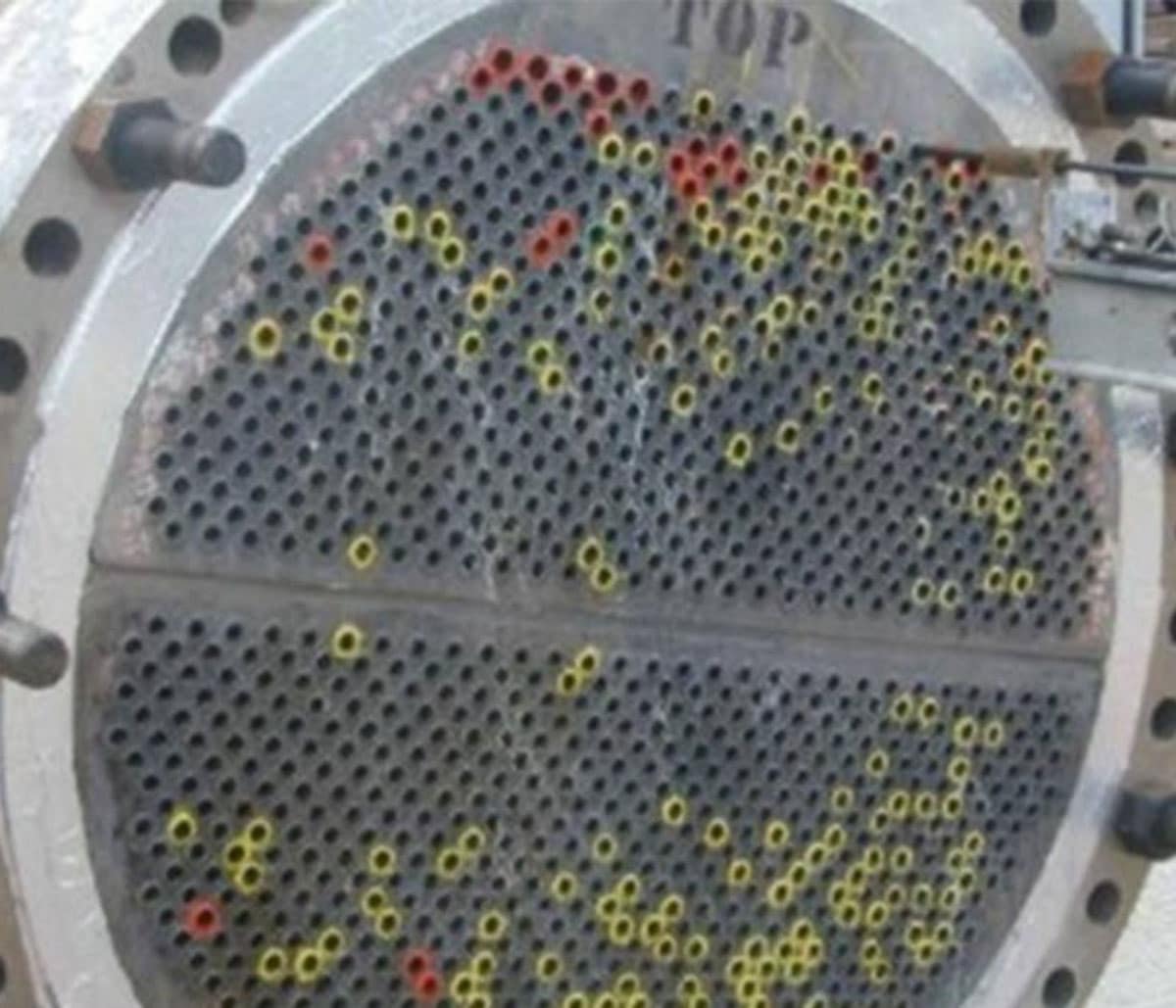

An Arabian gas liquefaction company had a problem with their titanium U-tube (hairpin) heat exchanger blocked by calcium carbonate and tenacious silicate deposits. IGS Tube Tech removed the hard deposits from within the fragile tubes and restored heat transfer efficiency.

“The hairpins were solidly blocked. This level of blockage and hardness factor has always previously meant a re-tube or full replacement. We had to take great care because the heat exchanger was titanium, perhaps the only one of its type that has been restored in this manner.”

Due to bespoke Intellectual Property being deployed, Tube Tech is happy to demonstrate and discuss the unique U-tube heat exchanger cleaning process if further information is required.

A spokesperson for the client said:

“We were very satisfied with the standard achieved. We had tried drilling, high-pressure jetting at 1,000BAR and various chemicals with no joy. Our objective was to unblock 5% of tubes to reach satisfactory performance.

Tube Tech achieved 7% in a short time and promised to attain 95%-plus if required. This avoided a full and expensive retube costing at least $250,000. We will have no hesitation in calling in Tube Tech again.”

CATEGORIES:

Contact our team today for expert advice and tailored solutions across a range of industries and applications.