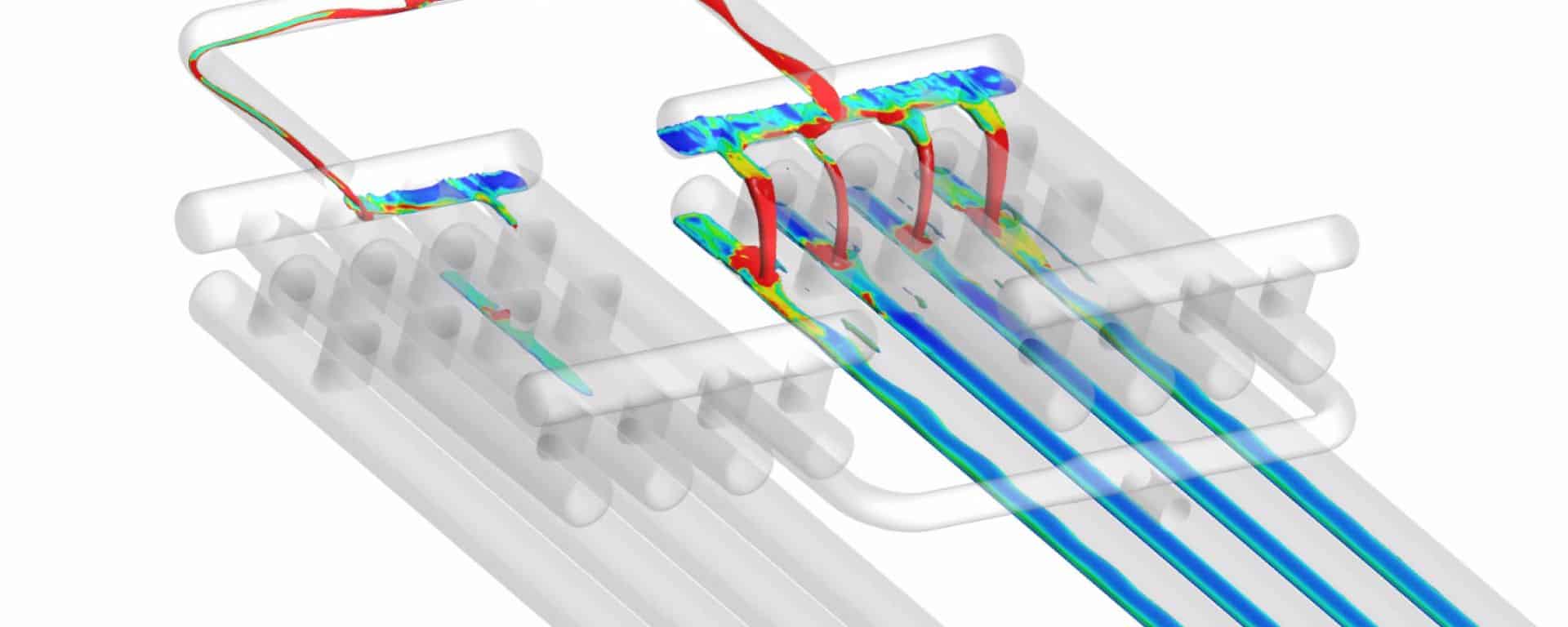

Transporting untreated wet gas from offshore facilities is often the only viable option for developing marginal fields or facilitating subsea completions. Despite being economically attractive, this process poses significant corrosion risks, particularly from H2S and CO2, to onshore infrastructure, especially finger slug catchers. Understanding and mitigating slug catcher corrosion is imperative for maintaining the equipment integrity and operational efficiency.

The presence of H2S and CO2 in wet gas systems can severely damage finger slug catchers and piping by corroding carbon steel surfaces. This results in leaks, loss of containment, and costly unplanned shutdowns. This section explores the chemistry behind H2S and CO2 corrosion, its impact on finger slug catchers, and why it’s a critical concern for the oil and gas industry’s offshore operations.

Corrosion attacks vulnerable areas, particularly the bottom sections of horizontal pipes, where CO2 and organic acids create corrosive solutions. H2S, especially at higher temperatures, reacts directly with steel, especially in the heat affected zones around welds, changes in metallurgy and micro-fissures metal, leading to formation of localized corrosion cell. Over time, pitting deepens, initiating corrosion fatigue cracks, causing leaks or ruptures.

The task of replacing damaged slug catchers represents a significant financial and logistical challenge. These components of the offshore transportation infrastructure are among the largest capital investments for upstream producers. With the long lead times for replacements, finding cost-effective and timely solutions for extending the life of these assets is a priority.

The quest for effective corrosion mitigation in slugcatchers often encounters limitations with traditional strategies such as chemical injection, protective coatings, and cathodic protection. These methods face challenges like the rapid washout of chemicals due to high fluid velocities and the failure of organic coatings over time, which also necessitate confined space entry for maintenance and repairs. The industry’s need for more reliable and sustainable corrosion prevention techniques has never been more pressing, prompting the exploration of advanced corrosion control methods that can withstand the harsh conditions of wet gas separation.

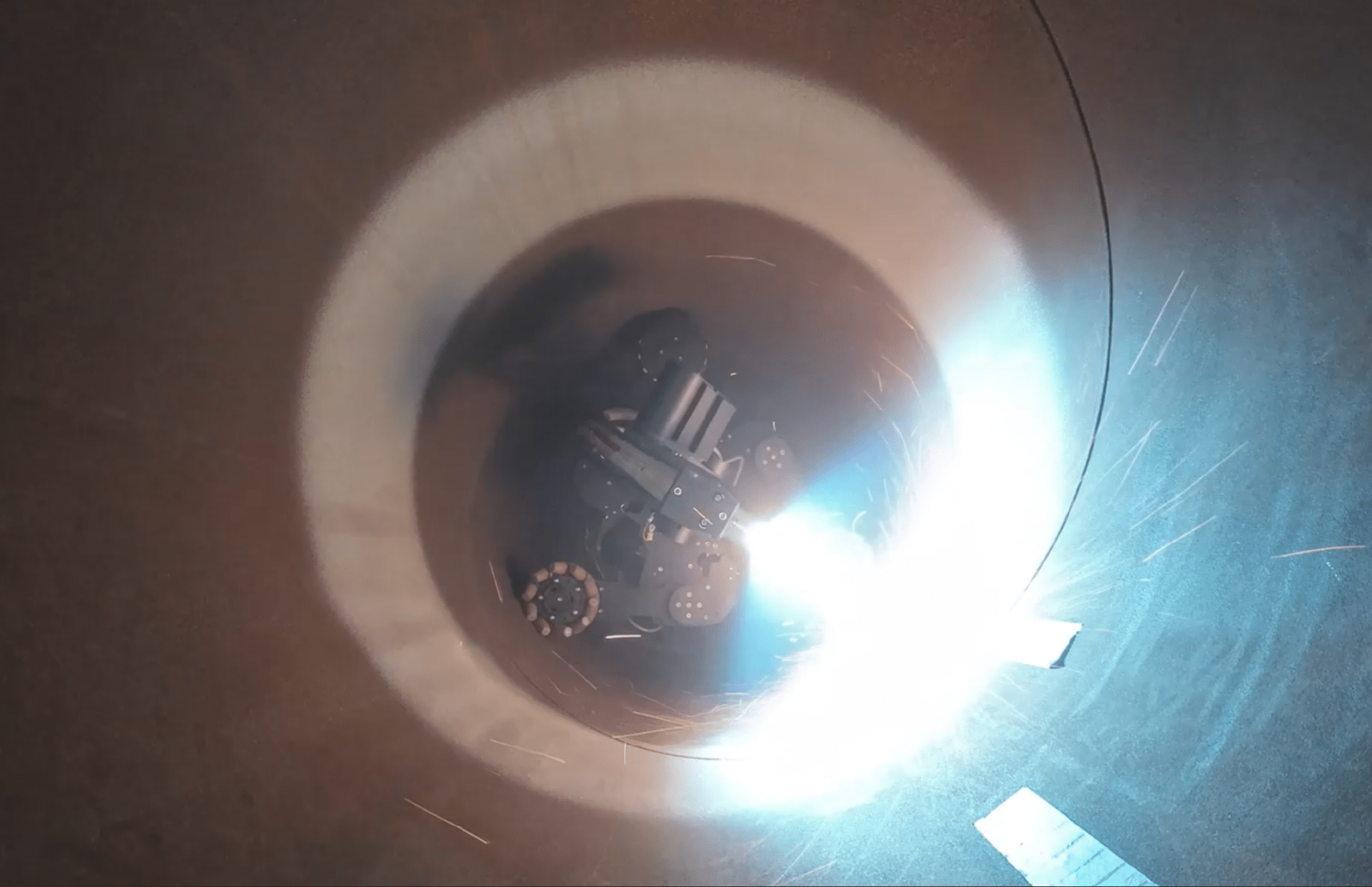

In response to the limitations of conventional corrosion control methods, the field-applied no-man-entry Metalspray technology presents a novel solution for enhancing the corrosion resistance of wet gas slug catchers and pipelines. The IGS Metalspray PipeID Rover is at the forefront of this innovation, offering comprehensive surface preparation, alloy upgrade, quality control, and debris removal services without the need for human entry.

This cutting-edge solution employs a self-propelled rover capable of navigating through pipelines to perform targeted alloy upgrades on areas susceptible to corrosion. Utilizing unique non-contact preparation tools, the system effectively removes corrosion products and inspects surfaces to ensure optimal metallurgical bonding and subsequent corrosion protection. Equipped with laser scanning and computer vision technology, the rover facilitates real-time integrity scans, ensuring thorough coverage and effectiveness of the corrosion protection cladding applied.

See how IGS can improve your slug catcher reliability