Shell and Tube Heat Exchanger Fouling Removal

Reduce Downtime and Maximize Profitability with TubeTech™’s Heat Exchanger Cleaning Service

TubeTech™ guarantees the removal of fouling from both the shell and tube sides of heat exchangers. Our advanced technology is engineered to handle any fouling type or severity, restoring performance to IRIS inspection standards—even in blocked or hard-to-access exchangers.

We specialize in cleaning twisted tube heat exchangers, also spiral tube or helical tube heat exchangers. Our proprietary systems are designed to access and clean these complex geometries thoroughly, without causing damage to the exchanger.

TubeTech™ works with refineries, chemical plants, manufacturing, and processing facilities worldwide to reduce downtime, improve thermal efficiency, and lower fuel consumption and emissions. Our solutions help asset owners extend equipment life, avoid costly replacements, and maintain optimal performance.

I’m here to help

Scott Donson

IGS Subject Matter Expert

TubeTech™ Specializes in Cleaning:

Twisted Tube Heat Exchangers

TWISTED TUBE® Heat Exchangers by Koch Heat Transfer offer more efficient and reliable performance results than some traditional shell and tube heat exchangers. The unique twisted design provides an increase in heat transfer surface area and as such is favored for more challenging heat exchange processes like hot crude oil versus viscous hot vacuum residue, for example.

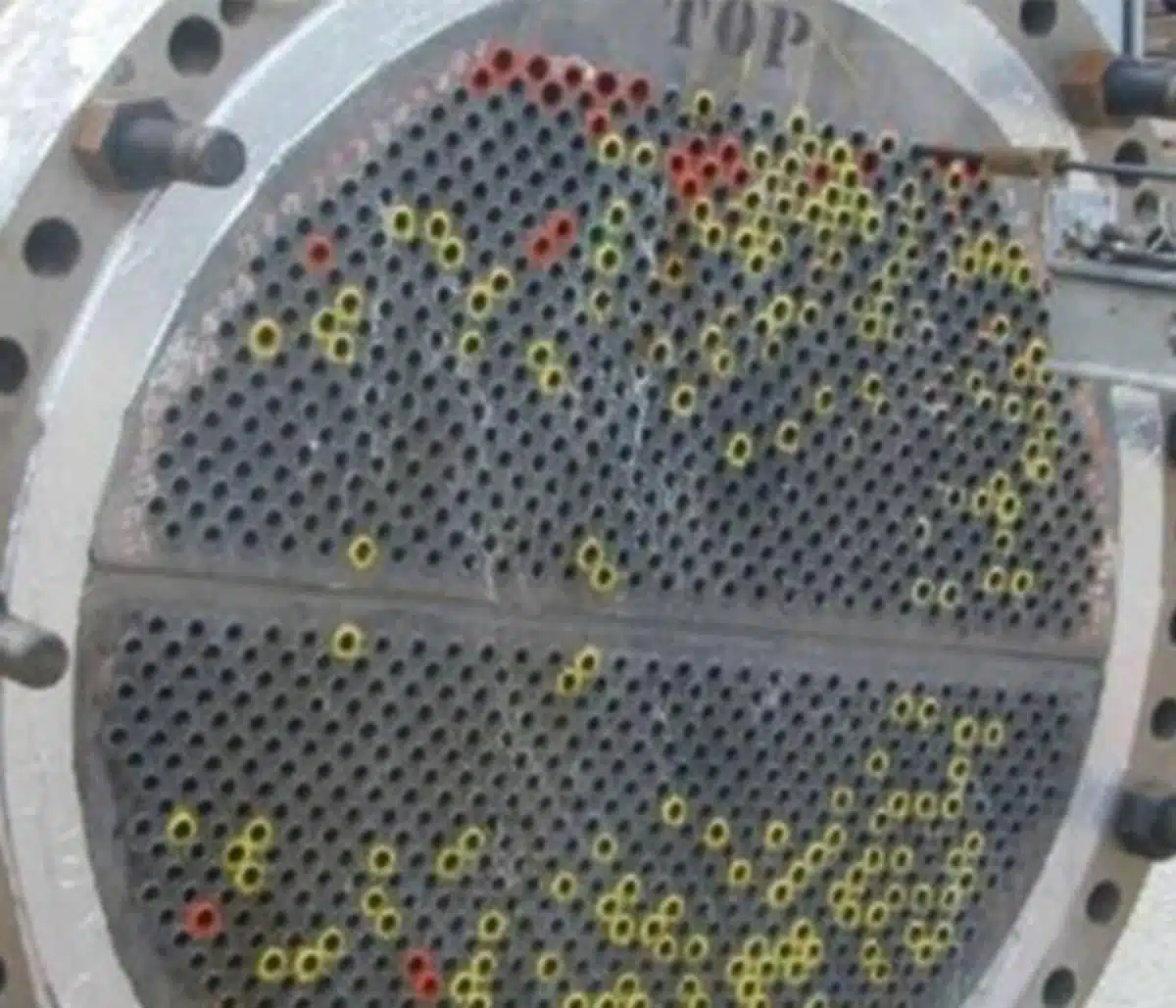

The Challenge – Heat Exchanger Fouling

Whilst TWISTED TUBE® Heat Exchangers typically have a 40% higher heat transfer coefficient, fouling can still accumulate in ‘cleaning lanes’ on the shell side. If fouling builds up, the exchanger can become very difficult to clean.

The Solution – Shell and Tube Heat Exchanger Cleaning

TubeTech™ has developed a technology specifically to clean TWISTED TUBE® Heat Exchangers. It works by cleaning the full length of the cleaning channels and penetrating precisely to remove any scale or blockages no matter where they are within the bundle.

U-Tube (Hairpin) Heat Exchangers

One of the most common heat exchangers in refineries and processing facilities is the straight or U-Tube hairpin shell and tube exchanger. These types of exchangers are popular as they maximize tube surface and heat exchange in a confined space and the bundle is easily removed for cleaning.

The Problem – Blocked Heat Exchanger

This type of heat exchanger commonly suffers from fouling build-up. Taking several exchangers offline can cost your facility hundreds of thousands of dollars in production downtime and traditional methods often fail to remove tenacious fouling.

How Can We Help?

TubeTech™’s engineered heat exchanger cleaning service gets your facility back up and running quickly with minimal disruption to processes. Our smart technology penetrates deep between tube rows to guarantee 90%+ clean, regardless of the type or severity of fouling.

TubeTech™ Shell & Tube Heat Exchanger Fouling Removal Case Studies

Heat Exchangers (Crude Train) Restored to Design Parameters at a Refinery

An Arabian gas liquefaction company shipped a titanium U-tube (hairpin) heat exchanger to TubeTech™’s UK research and development facility so that our dedicated team could remove calcium carbonate and tenacious silicate deposits from within the fragile tubes to restore heat transfer efficiency.

“TubeTech™ achieved 7% and promised to attain 95%-plus if required. This avoided a full and expensive retube costing at least $250,000.”

TubeTech™ Restores Offshore Crude Oil Heaters

The operator of one of the largest offshore projects in the North Sea required an effective heat transfer efficiency restoration solution for two of their crude oil heaters ready for inspection.

- Both crude oil heaters were fouled with a gooey consistency deposit believed to contain sand and other organic content.

- Both units required inspection and restoration to a suitable IRIS standard.

“Very good safety culture and professional approach. Technicians always on time and very professional – a credit to TubeTech™.”

Rapid Mobilisation and specialist technology succeeds where previous contractors failed

A facility located in South Africa had tried to remove fouling from its TWISTED TUBE Heat Exchangers by Koch Heat Transfer several times with limited success.

- 4x Twisted Tube Heat Exchanger by Koch Heat Transfer bundles each with 960 triangular pitch horizontal tubes.

- Client requested a 90% production standard of fouling removal to the internal and external surfaces.

- This critical path project was successfully completed within the timeframe specified by the client.

“We were really impressed with TubeTech™’s performance and how clean the bundles are – the cleanest we have seen them since installation in 2008!”

What do our customers say?

“We were really impressed with TubeTech™’s performance and how clean the bundles are – the cleanest we have seen them since installation in 2008!”

Process Engineer

Contact a Shell and Tube Heat Exchanger Cleaning Expert Today

90%+ Clean Guarantee, IRIS Inspection Standard, Exceptional Safety Standards, Up to 5x Faster Cleaning.