Amine Regenerator Pitting – On-Site Shell Alloy Upgrade Stopped Column Corrosion

HVTS Application to Amine Regeneration Pitting Issue Saves $20Mil

When faced with pitting corrosion in the Amine Regenerator Column, IGS HVTS provided an efficient, cost-effective, long-term solution for a Malaysian ammonia manufacturer.

This energy company in Malaysia operates various facilities across the country, including an ammonia plant, located on the East Coast of Malaysia.

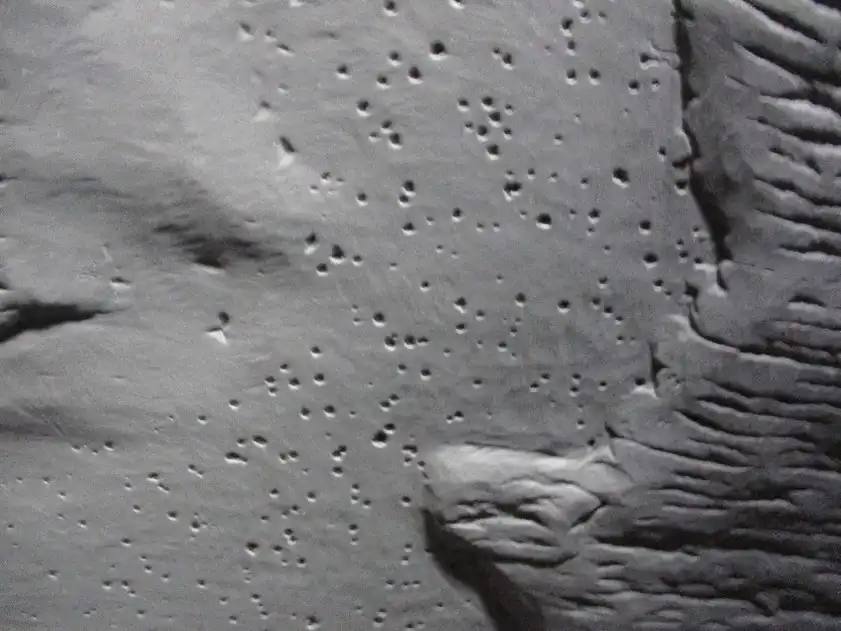

The Challenge: Pitting Corrosion in Amine Regenerator Column

The challenge faced by the ammonia plant involved their amine regenerator column, which experienced pitting corrosion in the unprotected carbon steel area. Despite previous patchwork with organic coatings, the corrosion persisted, prompting the need for a long-term solution.

Considered Solutions: Stainless Steel Cladding vs. Amine Regenerator Column Replacement

The plant explored two primary solutions for addressing pitting corrosion in the amine regenerator column: stainless steel cladding and complete column replacement. Both options were deemed expensive and time-consuming, causing additional two weeks+ of downtime, leading them to search for a more efficient and cost-effective alternative.

Selecting IGS HVTS as the Solution for Amine Regeneration Pitting

The decision-making process involved a meticulous evaluation, considering the plant’s HQ role as a technical authority overseeing various plants globally. After a year and a half of scrutiny and approval, the company selected IGS HVTS (High Velocity Thermal Spray) as the preferred solution.

Approval Process and Overcoming Concerns

Being a technical authority, the company scrutinized the system extensively, addressing concerns and ensuring compliance. This involved prequalification of the alloy, case studies globally and within the APAC region, material understanding, and collaboration with the local partner in Malaysia, Klay EnerSol.

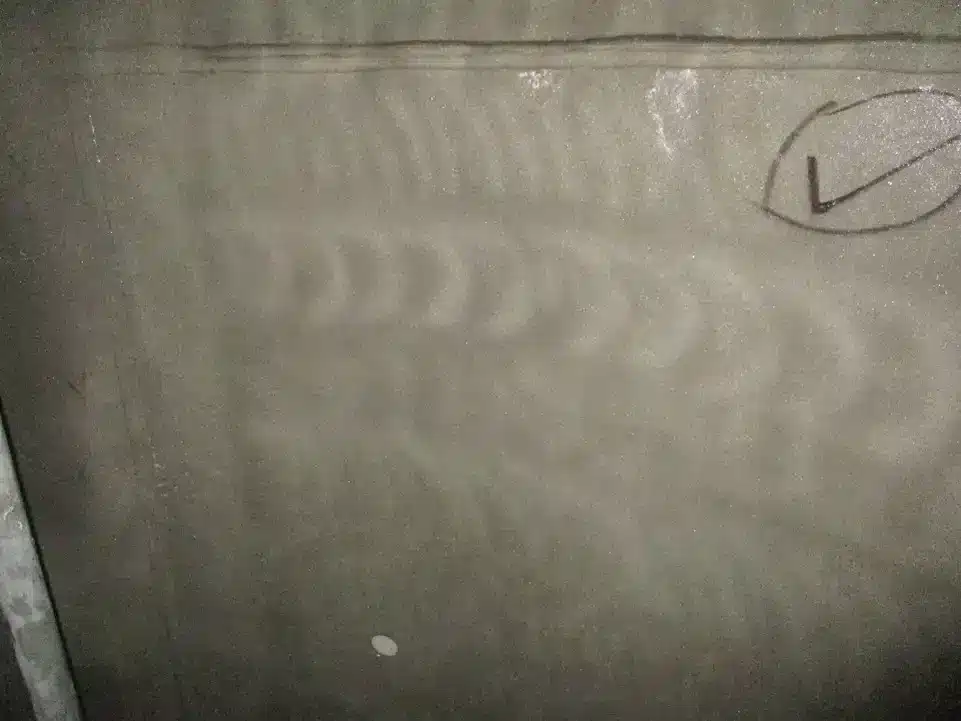

Amine Regenerator Column – HVTS Application Timeline

The IGS HVTS application commenced in September 2023. The application over a 76-square-meter area was executed efficiently, within only 4.5 days with IGS technicians working in nine half-day shifts.

Cost Savings and Benefits of HVTS for Corrosion in the Amine Regenerator Column

The key benefits for the chemical ammonia plant included the installation of a long-term corrosion barrier within a short timeframe, preventing further corrosion. Compared to alternatives like stainless steel cladding or column replacement, IGS High Velocity Thermal Spray saved the plant significant time and costs, potentially around $20 million.

Future Collaboration with IGS

The plant expressed satisfaction with the application, appreciating IGS’s unique technology. Since the successful project, the plant and its sister plants have shown interest in exploring IGS solutions for other equipment, showcasing a potential for future collaborations.

This case study demonstrates the effectiveness of IGS HVTS in providing innovative and efficient solutions for challenging corrosion issues in critical industrial equipment.

Related Case Studies:

- Severe Amine Column Corrosion Permanently Frozen

- CO2 Corrosion Mitigation in a Regenerator Column at LNG Plant

- A Short-term Saving has a Long-term Cost!

- H2S and CO2 Gas Vessels 10+ Years in Service

- HVTS Stops Sour Water Stripper Corrosion

- H2S Corrosion in an Upstream Separator Vessel Permanently Stopped

- Column Shell Corrosion Protection Verified

- Amine Regenerator Column Pitting – On-Site Shell Alloy Upgrade Stopped Column Corrosion

- Amine Regenerator H₂S Corrosion Protection

On-site Thermal Spray Coating Services from IGS:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.