Mitigating Chloride Stress Corrosion Cracking (CSCC) in Offshore Condensate Strippers

Offshore Corrosion Risks

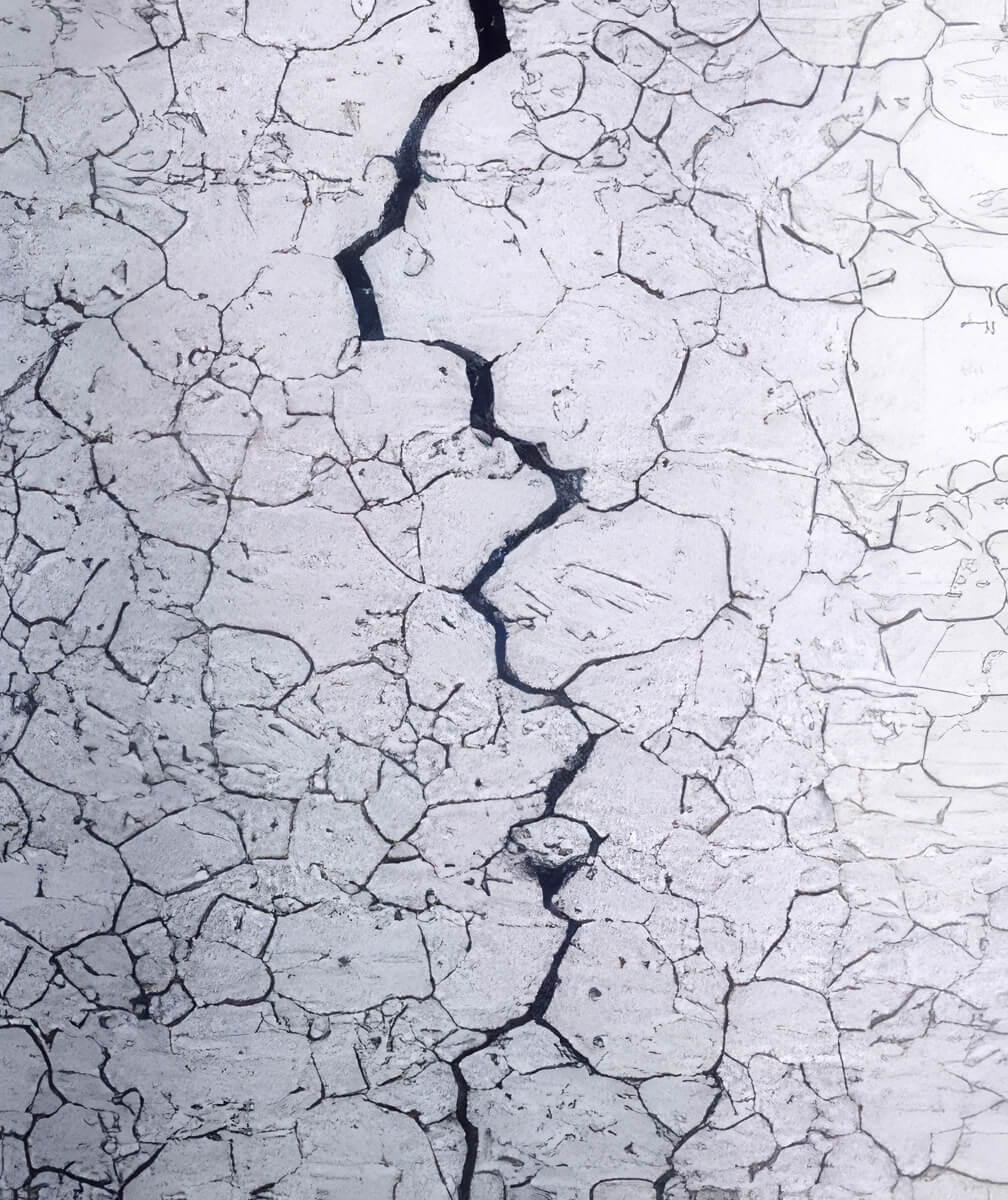

Chloride-induced Stress Corrosion Cracking (CSCC) is a critical challenge for operators working in high-chloride environments, particularly in offshore oil and gas facilities fabricated or clad with stainless steel.

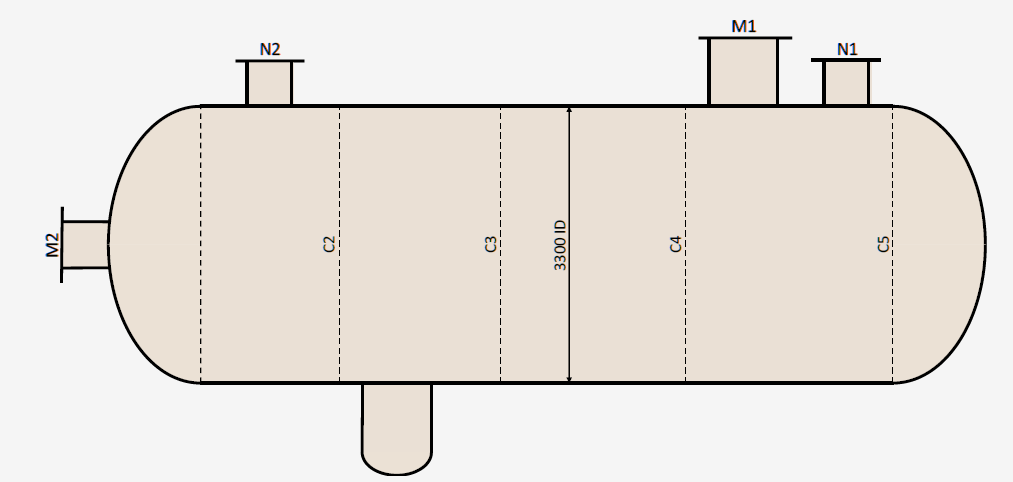

In 2013, IGS was contracted to provide an offshore corrosion protection solution for six process vessels in the Arabian Sea, four discharge drums and two condensate strippers. The condensate strippers were especially vulnerable due to their operating conditions and their essential role in the hydrocarbon processing chain.

Condensate Stripper Corrosion Challenges

Condensate strippers are vital to hydrocarbon processing, separating light components from condensate. These vessels face severe corrosion risks offshore, including:

-

Chloride-rich process fluids from formation water and additives

-

Frequent temperature fluctuations creating thermal stress

-

Pressure variations adding mechanical stress

-

Aggressive chemical environments that accelerate CSCC, particularly at welds and vapor-liquid interfaces

The Added Impact of H₂S in Offshore Environments

Hydrogen sulfide (H₂S), present in up to 30% of global natural gas reserves, further complicates condensate stripper corrosion. H₂S accelerates CSCC when combined with chlorides, while also contributing to:

-

Crevice corrosion in stagnant zones

-

Sulfide stress cracking in high-strength steels

-

Hydrogen embrittlement in critical assets

Together, these mechanisms compromise vessel integrity and increase the risk of unplanned shutdowns.

Why Stainless Steel in Offshore Vessels is Susceptible

Austenitic stainless steels, commonly used in condensate strippers, are particularly susceptible to CSCC under offshore conditions. The combination of chlorides, tensile stress, and elevated operating temperatures can rapidly initiate and propagate microcracks, especially in heat-affected zones (HAZ) and welded areas. Left unchecked, this leads to accelerated degradation and potential equipment failure.

HVTS® Cladding: Advanced Offshore Corrosion Protection

To mitigate these risks, IGS deployed HVTS® (High Velocity Thermal Spray) cladding in 2013 during a planned offshore turnaround. This engineered surface technology was applied to the most vulnerable areas, including:

-

Vapor-liquid interface zones

-

Welds and heat-affected areas

-

Nozzles and connections

-

Bottom sections exposed to concentrated fluids

HVTS® applies a dense, corrosion-resistant alloy with high bond strength, creating a long-term protective barrier between the steel substrate and aggressive process conditions.

Key Benefits of HVTS® Offshore Applications

-

3x faster application than welding

-

Compatible with existing weld overlays

-

No distortion or HAZ issues from welding heat input

-

Superior long-term corrosion and erosion resistance

-

15+ years of protection in offshore operations

Inspection Results: Proven Long-Term Performance

In 2016, three years post-installation, detailed inspections confirmed the reliability of the HVTS® system:

-

No new CSCC formation detected

-

Complete integrity of all applied cladding

-

Excellent protection at vapor-liquid interfaces

-

No degradation despite aggressive offshore service conditions

Conclusion: Extending Asset Life Offshore

The application of HVTS® cladding in condensate strippers has proven to be a robust, long-term solution for chloride stress corrosion cracking in offshore oil and gas assets. By delivering reliable asset integrity management, HVTS® has preserved vessel condition, extended equipment life, and ensured process safety in one of the most demanding environments.

Related Case Studies:

- Ethylene Quench Tower Corrosion Mitigation Saves $1.8Mil

- Cracker Quench Column Corrosion Stopped with IGS HVTS Cladding

- A Short-term Saving has a Long-term Cost!

- Column Shell Corrosion Protection Verified

- HVTS Prevents Corrosion Attack in a Regenerator Column at LNG Plant

- Severe Amine Column Corrosion Permanently Frozen

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.