Primary Reformers

Steam Methane Reformers: Debottlenecking and Furnace Efficiency Improvement for Ammonia and Methanol Production

The enhanced efficiency of the furnace box can be utilized to alleviate excessive temperatures in the convection section, increase the capacity of the steam reformer or extend the lifetime of the catalyst tubes. Several other secondary benefits are obtained by sealing the refractory walls with the ceramic coating material. The coating has been utilized successfully in syngas reformers of different designs in ammonia, methanol and hydrogen production facilities.

Efficiency Gains for Ammonia and Methanol Plants

The enhanced radiant efficiency of the furnace box can be leveraged to:

-

Alleviate excessive temperatures in the convection section

-

Increase the reformer’s processing capacity

-

Extend the lifetime of catalyst tubes

Additional secondary benefits are achieved by sealing refractory surfaces with our ceramic coating material, such as reducing energy losses and improving uniform heat distribution. The coating has been successfully applied in syngas reformers of varying designs across ammonia, methanol, and hydrogen production facilities worldwide.

Watch the video Cetek High Emissivity Coating for Fired Heater Refractory

Thermal Efficiency of the Steam Methane Reformer Furnace

SMRs typically achieve thermal efficiencies in the range of 45–60%, with another 35–50% of the heat recovered from the flue gas in the reformer’s convection section. This recovered heat is then used to preheat reformer feed, process air, superheat steam, and preheat boiler feedwater or combustion air.

Thermal efficiency improvements are achieved through the use of high emissivity ceramic coatings that boost radiant heat transfer from furnace walls to catalyst tubes. However, actual gains depend on reformer design and real-world operating conditions.

Sidewall-fired and terrace-wall-fired reformers, commonly found in ammonia and methanol plants, show superior results due to their ability to utilize enhanced radiation from the furnace walls more effectively.

Reformer Surface Emissivity and Its Impact

High emissivity surfaces radiate energy across a broader wavelength spectrum, reducing interference from CO₂ and H₂O present in the flue gas. When flame radiation hits a high-emissivity surface, it is absorbed and re-emitted as “black body radiation” — enabling deeper penetration into the furnace atmosphere and more effective heating of the catalyst tubes.

In contrast, low-emissivity surfaces reflect untransformed radiation, which is more easily absorbed by the flue gas and lost to the stack — representing wasted energy.

Improved radiant heat transfer efficiency leads to a lower flue gas temperature, which impacts the convective heat transfer in the SMR’s convection section. Since the flue gas in this section is used to generate steam and preheat fluids, IGS carefully analyzes the heat transfer and absorbed duty balance to ensure optimal system performance.

The improvement in radiant heat transfer efficiency leads to a reduction in flue gas temperature. This has consequences in the convective heat transfer in the convection sections of the primary reformer. In the convection section, heat in the flue gas is used to produce steam and preheating of combustion air process fluids. We carefully examine the heat transfer/absorbed duty balance to ensure that the balance is not adversely affected.

Cetek’s Evaluation Process for Ammonia and Methanol Reformers

IGS Cetek’s high emissivity ceramic coatings have demonstrated measurable benefits across hydrogen, ammonia, and methanol reformer types. To maximize results, we conduct a detailed technical evaluation prior to application. This includes an assessment of the radiant section gains and their impact on the convection section.

Approved SMR applications — particularly in ammonia and methanol production facilities — typically yield productivity improvements ranging from 1.0% to 5.0%, whether through energy savings or increased throughput.

Emission Reduction in Steam Methane Reformers

The reduction in flue gas temperature leads to a significant reduction in thermal NOx emissions. The typical reduction in NOx emissions in steam methane reformers is 20% to 30%, irrespective of burner type. CO2 emissions are reduced proportionately with the productivity benefits – with gas consumption reduction.

Ceramic Fiber Refractory Dusting in SMRs

Cetek’s ceramic coatings (high emissivity or neutral emissivity) provide encapsulation of ceramic fiber (blanket, modules, or panel) insulation. When coated, there is no loss of friable fiber from radiant sections. Therefore, no fouling of radiant section tubes/catalyst tubes, convection section tubes, screens of SCR (Selective Catalytic Reduction) units or loss to the environment through the stack.

Benefits of High Emissivity Coatings for Reformer Efficiency

The expected benefits from coating have been realized in many fired heaters and reformers. The typical 1.0-5.0% capacity increase or energy savings provide a significant benefit. Combined with more uniform heat flux and heat transfer from re-radiating refractory surfaces, lower bridgewall temperature and emissions, this technology makes a meaningful contribution to the overall reformer performance.

Extend Reformer Tube Lifetime

The performance life of the coating system applied to a refractory surface of the Steam Methane Reformer is related to the furnace box temperature and exposure to localized flame impingement. The extended lifetime benefit is typically 6-8 years, after which we can reapply the coating to regain the maximum performance.

WATCH: Enhanced SMR Efficiency: Fuel & Emissions Reduction delivers a Sustainable Decade-long Benefit

Furnace Efficiency Specialist Larry Emch recalls an application where IGS reduced SMR fuel consumption by 2%, leading to lower CO2 and NOx emissions.

This sustainable decade-long benefit was achieved with the application of a Cetek refractory encapsulation coating within the SMR’s radiant section.

By closing the performance gap and increasing the efficiency of the SMR unit, IGS delivered:

- 2% fuel saving

- CO2 reduction

- 9% complimentary reduction in nox

- Reduced bridgewall temperature

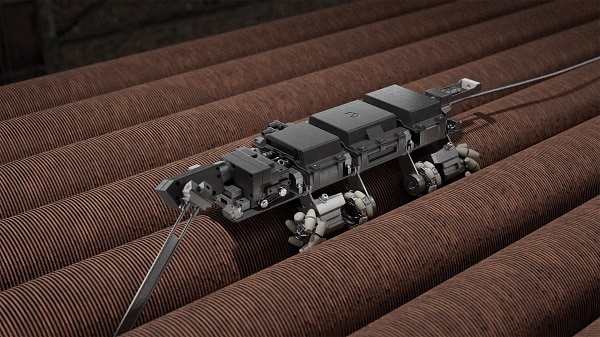

TubeTech™ Fouling Removal Services

Heat Exchanger Fouling Removal Services:

- Shell and Tube Heat Exchanger Fouling Removal

- Fired Heater Furnace Fouling Removal

- Twisted Tube Heat Exchanger Fouling Removal

- U-Tube (Hairpin) Heat Exchanger Fouling Removal

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.