A Successful Revamp of a 40-year-old Steam-Methane Reformer Furnace

This case study examines a successful application of Cetek high emissivity coating to the radiant section of an SMR reformer which was experiencing excessive fuel firing.

The Asset: An SMR reformer at Valero Benicia Refinery

The Valero Benicia Refinery is located northeast of San Francisco which processes sour crude oils into gasoline, diesel, jet fuel and asphalt.

The Problem: Excessive Fuel Firing in the Radiant Section of F-301 and F-351

Excessive fuel firing in the radiant section of F-301 and F-351. Since the heaters were fiber lined, debris would migrate into the convection section and foul the tubes.

Convection section needed to be cleaned at every turnaround.

The Solution: Cetek High Emissivity Coating

IGS applied Cetek high emissivity coating improving the radiant heat transfer efficiency and resulting in a ~9% fuel savings and 16% NOx reduction.

Refractory Coating Benefits

The application of ceramic coatings onto refractory surfaces delivers a range of benefits, including:

- Increased production rate and/or fuel savings

- Minimized fouling of the convection section and the SCR catalysts

- Lower stack and bridgewall temperature, reduced NOx emissions

- Cetek’s ceramic coating also effectively encapsulates the refractory surfaces in the radiant chambers thereby minimizing and /or eliminating fouling of the convection section and the SCR catalysts with highly insulating fibers.

Revamping 40-year-old Reformer Furnaces

The Valero refinery, located in Benicia California, was built in 1968 and has been revamped several times since then.

The refinery operates two steam methane reformers, designated F-301 and F-351. The configuration of each reformer furnace consists of two radiant chambers with a common convection section. Each radiant chamber is sidewall fired, using Low NOx burners. There is a single row of catalyst tubes in the center of each radiant chamber.

Dealing with Excessive Fuel Firing in the Radiant Section

The radiant sections of F-301 and F-351 are both lined with ceramic fiber refractory. During operation, unencapsulated ceramic fiber deteriorates as surface fibers crystallize and become friable. Abrasion from hot flue gases cause debris to migrate into the convection section and foul the tubes.

The convection sections needed to be cleaned at every turnaround, which meant continued annual maintenance costs.

Left as-is the ceramic fiber will continue to deteriorate, continuously fouling the convection section and eventually requiring a re-lining. At the same time, excess fuel firing would be needed to account for the significant fouling in the convection section preventing steam generation and process preheat.

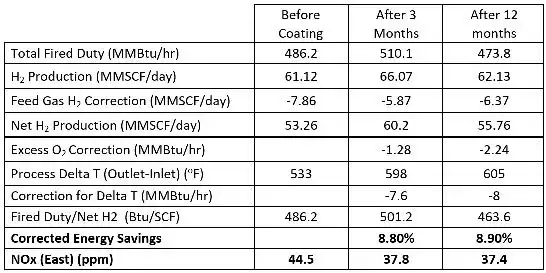

Summary Calculation Showing Energy Savings from Cetek High Emissivity Coating Application to Radiant Section Refractory Surfaces in F-301. *Radiant benefit does not account for some convection steam loss.

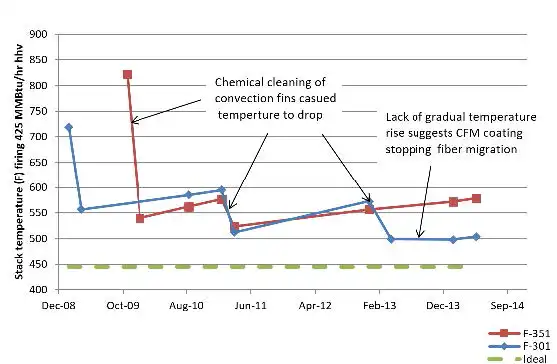

Effectiveness of Cleaning Convection Section Tubes and Encapsulating Radiant Section Ceramic Fiber Modules with Cetek Ceramic Coatings

Cetek Application Results

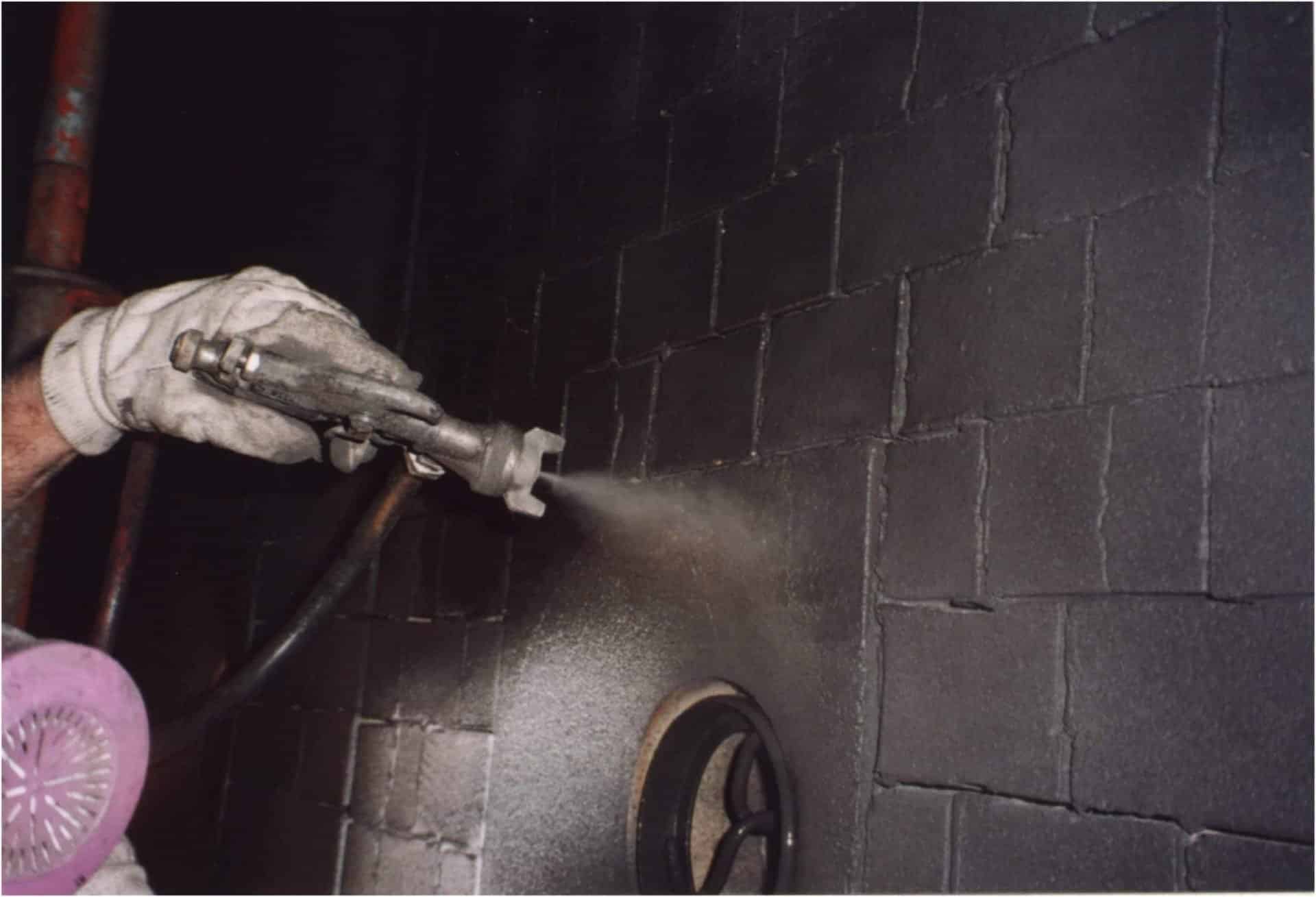

IGS Cetek team was invited to install the high emissivity ceramic coating system to the refractory surfaces in the radiant chambers of one of these reformers, F-301, to improve the radiant heat transfer efficiency and encapsulate the refractory lining & to reduce or eliminate the deterioration of the same.

The results of the application were exceptionally good.

- Energy saving: calculated after 3 months in service (8.8%) and again after 12 months (8.9%).

- A 16% reduction in NOx emissions, resulting from the radiant efficiency increase and lower flue gas temperature.

In addition to the energy savings, a secondary benefit was expected. As a result of the Cetek ceramic coating, the radiant ceramic fiber refractory should be essentially “encapsulated”.

In fact, the carryover of fiber particles into the convection section and fouling of heat transfer surfaces appears to have been reduced, as indicated by the fact that the previously higher stack temperature remained stable for a longer period of time.

Cetek Ceramic Coating Technology

Cetek pioneered the use of high emissivity ceramic coatings applied to the refractory surfaces in radiant sections of fired heaters and tubular reformers.

The emissivity coatings have superior longevity and Cetek’s experienced technicians apply it on-site to the refractory linings of process heaters/furnaces.

Book a meeting

IGS is here to provide information, answer questions and create an effective solution for your needs.