How to Improve Air Cannon Performance in Cement Plants

Poor Air Cannon performance can cause blockages and build-up issues in cement plants. The improper operation of air cannons leads to $Millions in loss of production and efficiency costs.

Air cannons when applied properly will eliminate blockage and buildup issues within coolers, feed shelves, riser ducts, cyclones, and other applications in the preheater towers as well as silos.

What contributes to air cannon blast effectiveness?

The effectiveness of a blast from an air cannon is determined by many factors. Location, orientation, and type of nozzle applied to the cannon are instrumental in the success of an air cannon installation. The type of blast from the cannon also affects its ability to effectively remove any buildup, blockage,and clinker.

There are two main types of air cannon blasts or discharges, a Pusher, and a Blaster. Both are effective in the correct application, but the key to success is applying the correct blast style to the type of material being moved and the desired results.

What does a Traditional Air Cannon Consist of?

Traditional air cannons from all manufacturers consist of a single air receiver tank with a firing/piston assembly to control the blast of compressed air. The firing assembly may be externally attached to the tank or, more recently, internal to the tank. Either way, the air cannon has always been mounted to a nozzle or pipe which had been installed in the location where material buildup needed to be removed.

What is the Problem with Traditional Air Cannons?

Traditional air cannons requiring to be mounted directly to the blast nozzle have always presented numerous problems for the plant, including:

- The industrial air cannon is mounted very close to the process resulting in extreme heat and material from the process impacting the cannon. These are the major contributors to any company’s air cannons failing.

- Mounting the air cannon this close to extreme heat makes it very difficult, at times impossible, to perform any maintenance duties to keep the cannon operating.

- Oftentimes, the nozzles and cannons are mounted very high on a silo or structure. Performing maintenance on these cannons requires expensive scaffolding. Quite often no work is done to keep these cannons working. It is also very difficult for the plant to determine if these cannons are even functioning.

- Many applications require mounting numerous air cannons close together, one for each nozzle. This restricts or prohibits the ability of plant personnel to perform other required duties in this area. If more cannons are needed in the future, it is very difficult to add any in these situations.

What is the Solution to Achieve Improved Air Cannon Performance?

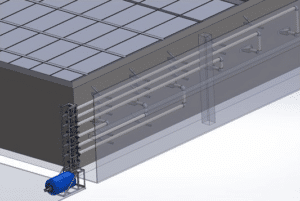

The new IGS Multiplier minimizes or eliminates these “Standard Air Cannon” drawbacks. IGS applies one single air cannon to a Multiplier system that replaces multiple single traditional air cannons offering many benefits over traditional air cannon installation.

The Super Cannon can deliver greater cleaning energy than the standard air cannon. This increased energy leads to improved cleaning with the following benefits:

- The system is mounted remotely from the blast nozzles to allow easy access for maintenance. This is very important to ensure the proper and ongoing operation of the cannon.

- Remote mounting is safer for plant personnel to perform maintenance work. It is also much cheaper because no scaffolding is required if the nozzles are mounted very high.

- The ports on the Super Cannon keep the cannon’s internal firing assembly protected from the heat and material of the process greatly adding to the life of the air cannon.

- There is only 1 cannon to maintain no matter how many blast ports there are on the system. This is a big saving in maintenance dollars.

- The Super Cannon allows for the easy addition of more blast ports if they are needed in the future. This is much cheaper than purchasing additional traditional cannons.

- Access for plant personnel to conduct other required activities in the area is much greater without multiple standard air cannons mounted in close proximity.

Live and On-demand Webinar

To find out more about air cannon performance in the cement industry, you can register for our latest webinar to watch live or on-demand.

“5 Reasons Air Cannons Fail in Cement Applications”

Jeff Shelton, an air cannon expert with more than 40 years’ experience maintaining, retrofitting, installing, and designing air cannons and their components will dive into 5 main reasons why air cannons fail in cement applications, including:

Poor Reliability

- Not protecting the air cannon from the environment

- Installing air cannons in inaccessible locations

- Air problems, not being able to get replacement parts Poor Cleaning

- Poor cleaning due to the wrong nozzle, and often not enough cleaning energy

- Poor cleaning due to the wrong location

Register, here: 5 Reasons Air Cannons Fail in Cement Applications