Hot Convection Cleaning

Removing Convection Section Fouling & Scale During Furnace Operation

Is the convection section in your fired heater experiencing reduced performance and declining efficiency? Symptoms such as low steam production, inadequate process pre-heat, and elevated stack temperatures are often clear indicators of fouled or scaled convection section tubes. Over time, accumulated deposits restrict heat transfer, increase fuel consumption, and negatively impact overall heater performance.

Hot-tek™ Hot Convection Cleaning is an online cleaning solution designed to remove years of fouling and scale from convection section tubes while the heater remains in service. Executed safely under full-load operating conditions, this process restores heat transfer efficiency without requiring a shutdown or interruption to production.

Hot Convection Cleaning Process

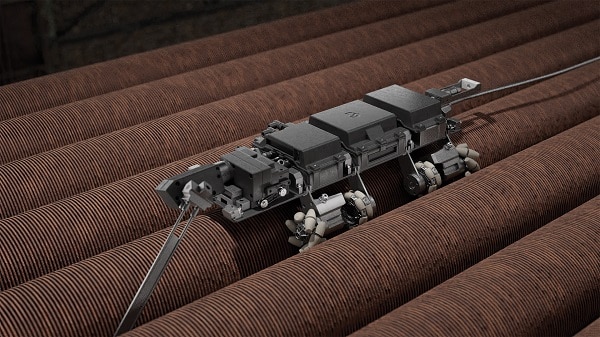

The Hot Convection Cleaning process uses high-velocity, consumable abrasive media projected through specially engineered application lances to effectively blast away stubborn deposits from tube surfaces. This proven method safely removes buildup from finned and bare tubes without damaging the tube metallurgy, allowing operators to recover lost performance and extend run length.

Hot-tek online convection tube cleaning is an efficient, environmentally responsible, and safe solution that delivers measurable results, often within hours, while the heater stays fully operational. By removing years of fouling and scale without production loss, this patented process helps restore productivity, improve asset reliability, and reduce operating costs.

Typical Results of the Hot Convection Cleaning Process

Facilities utilizing Hot-tek Hot Convection Cleaning commonly experience the following benefits:

- Increased heat transfer efficiency in the convection section

- Increased steam production

- Improved process pre-heat and heat recovery

- Lower stack temperatures and improved thermal efficiency

Before Hot-tek Hot Convection Cleaning

After Hot-tek Hot Convection Cleaning

Hot-tek’s Lancescope™

For applications involving limited access or complex convection section geometry, Hot-tek’s Lancescope™ system can be integrated to provide real-time visibility and targeted cleaning of hard-to-reach areas. In addition, Hot-tek has the capability to safely design and install engineered access ports, facilitating both the current hot convection cleaning operation and future maintenance activities

WATCH VIDEO: How Long Does Hot Convection Cleaning Take?

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.