HVTS® Mitigates Fireside Corrosion and Preserves Steam Reliability at a Regional Power Facility

Plant and Challenge Description

A power facility plays a critical role in delivering both power and process steam to industrial consumers, including a large corn processing operation. One of its 200MW pulverized coal-fired units had long been reliable, but the installation of Low NOx burners introduced an unintended consequence of accelerated fireside corrosion near the sootblower openings. This led to localized thinning of the tube wall, jeopardizing uptime and equipment longevity.

Historically, the team relied on pad welding to manage boiler tube thinning, but repeat maintenance and growing asset risk prompted the plant’s engineering leaders to seek a longer-lasting solution. Their primary objective was to extend waterwall life, avoid unscheduled outages, and reduce repetitive repair cycles.

Challenge – Pad Welding Unsuitable for Oxygen-Reduced Atmosphere

The facility’s engineers considered several options, including full boiler tube replacement and widespread weld overlay. Both approaches posed significant capital expense and schedule risk, particularly in a constrained outage window. HVTS® (High Velocity Thermal Spray) cladding emerged as a faster, more targeted solution, with a strong performance track record in high-temperature, high-corrosion environments.

Solution – IGS HVTS® Cladding

IGS proposed High Velocity Thermal Spray (HVTS) cladding — a fast, targeted solution proven in high-temperature, high-corrosion conditions.

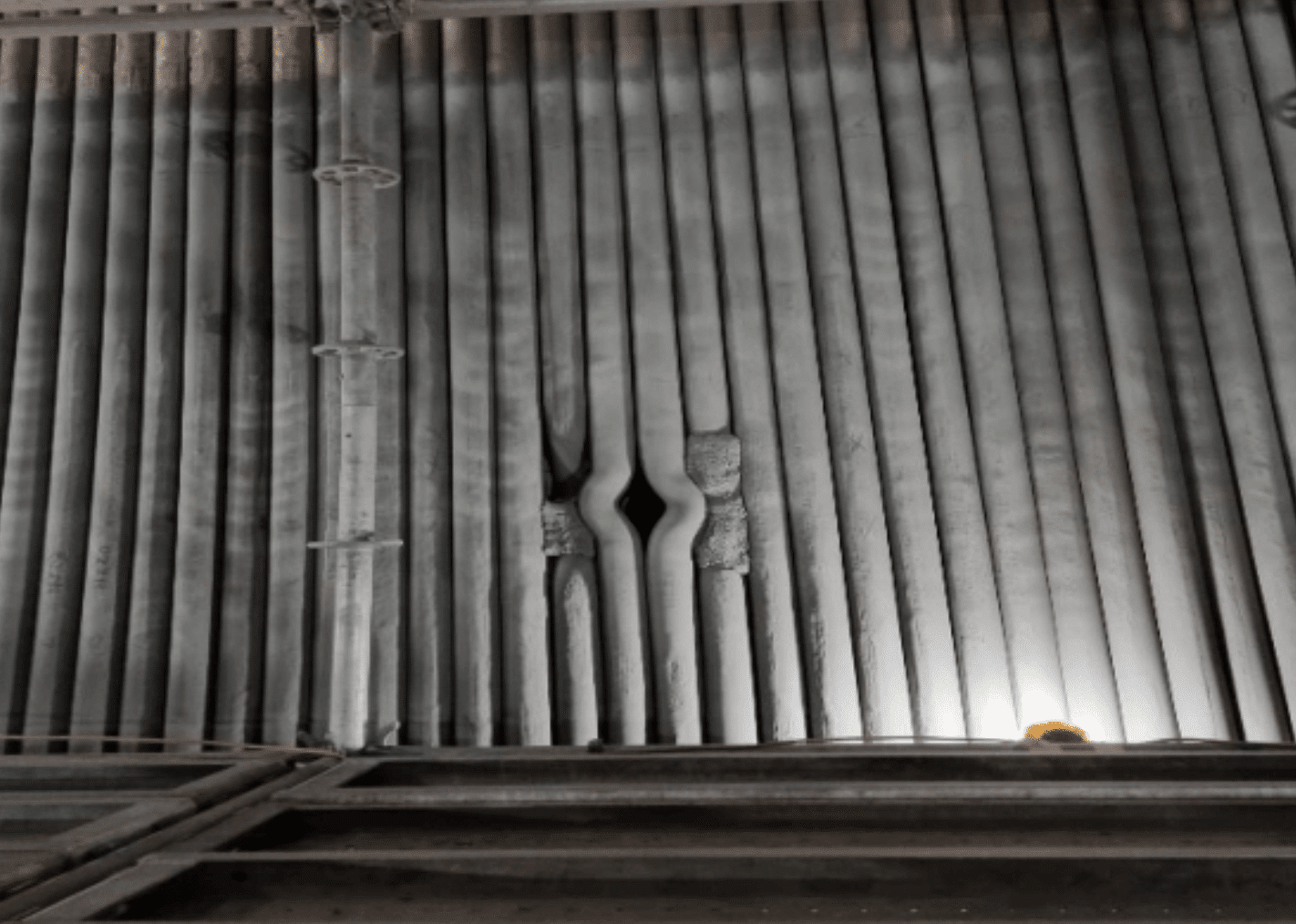

The first phase included two 7-foot HVTS cladding bands around each sootblower row, focusing on areas most affected by erosion and sulfidation. This approach optimized cost, coverage, and schedule without extending the outage.

HVTS Cladding Installed Within Spec and Ahead of Schedule

IGS mobilized during a planned outage and applied HVTS with a topcoat for enhanced corrosion resistance.

Despite limited surface prep time and previous weld repairs, the project was completed ahead of schedule, covering 1,643 sq ft across four boiler walls.

All quality benchmarks and safety standards were met, confirmed by Magnetic Lift Off (MLO) thickness data.

Life Extension Achieved in Critical Wear Zones

-

Corrosion and erosion halted in treated areas.

-

Integrity confirmed during inspection 2.5 years later.

-

Plans were initiated to extend the HVTS bands by 3.5 feet above and below each sootblower for continuous protection.

-

The project opened new opportunities for future IGS applications across sister sites.

IGS HVTS cladding stopped high-risk erosion and positioned the facility for sustained boiler reliability.

That’s Asset Vitality.

Client Quote

“This project was about more than just mitigating corrosion; it was about helping the plant maintain the reliability of their steam supply to support critical operations.”

— Dave Simcox, Business Development Manager, IGS

Related Questions:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.