Offshore Slug Catcher Corrosion Mitigation Saves $7.78M

Mitigating Slug Catcher Corrosion – Process Overview

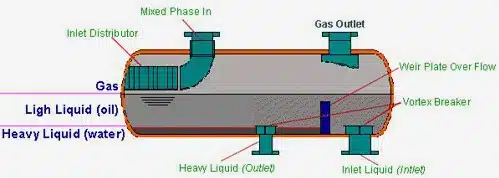

Pipelines that transport both gas and liquids together, known as two-phase flow, can operate in a flow regime known as slugging flow or slug flow. A slug catcher is a vessel with sufficient buffer volume to store the largest slugs expected from the upstream system. The slug catcher is located between the outlet of the pipeline and the processing equipment. The vessel is also used to separate out water from a production line.

Integrity Limiting Corrosion of Slug Catcher

A high pressure vessel taking feed directly from a production pipeline is employed to separate gas, oil and produced water. In order to provide corrosion resistance, the heavy wall slug catcher was strip weld overlayed with a 316SS alloy as originally manufactured. This overlay began to exhibit pitting corrosion. In order to protect the carbon steel from aggressive corrosion, it was necessary to prevent any further degradation.

Previous Mitigation Strategies for Slug Catcher Corrosion

The initial vessel fabrication required a 50-70mm thick carbon steel shell, lined with a strip welded 6mm 316SS weld overlay in the initial fabrication. As this material began to exhibit mild pitting, a permanent repair solution was sought. Localized applications of high temperature epoxy systems were not effective.

High Velocity Thermal Spray (HVTS) – New Application Technology

An offshore production platform contained two slug catchers that took oil/water/gas feed directly from the well. Having only seen several years of service, it was noted that shell pitting had occurred on the as-manufactured 316SS strip clad weld overlayed surface. The temperature and pressure service conditions precluded the use of any polymeric coating system.

The initial repair method considered was to weld overlay the shell with a second overlay cladding with a NiCrMo alloy. As an alternative, a high velocity thermal spray coating was also considered with a similar alloy. The thermal sprayed coating system was evaluated under similar process conditions and specified as an acceptable alternative

Turnaround Decision Process – Risk Mitigation

Due to the tremendous cost associated with the replacement of two large vessels in the middle of a platform, two viable cladding solutions for this application were considered. The initial intent to weld-overlay the internal surface with an automated weld overlay procedure was not viewed favorably due to a required working window of 30 days in a field shutdown to effect the repair.

Thermal Spray was considered and after favorable test results a decision was made to coat the internal surface of the vessel with a High Velocity process as this only required 10 days of access which was within the original turnaround schedule. Due to the difficulty of satisfactory access of the thermal spray process to small bore nozzles, all nozzles 8” and lower were weld overlayed with an automated bore welding procedure. The welding process took place simultaneously to the internal coating.

Sour service conditions typically required post weld heat treatment per ISO15156, however, the procedure developed for the nozzle welding limited heat input through the existing 316SS to the carbon steel to maintain a low enough hardness and preclude any PWHT need. As the pitting was shallow, very little grinding was required to prepare the surface. Each vessel was shutdown serially, requiring careful work procedures associated with a live platform.

Inspection of Slug Catcher Corrosion / Integrity Assessment

Due to the non-magnetic substrate associate with the existing internal cladding, additional process controls were required to ensure even surface coverage. Welding procedures for the nozzles were required in all positions due to horizontal, inclined and vertically oriented positing. The largest nozzles welded were 8” and the smallest 1.6” internal diameter. Manways and flange faces were also protected with HVTS, and special masking was employed to protect the ring joint gasket faces.

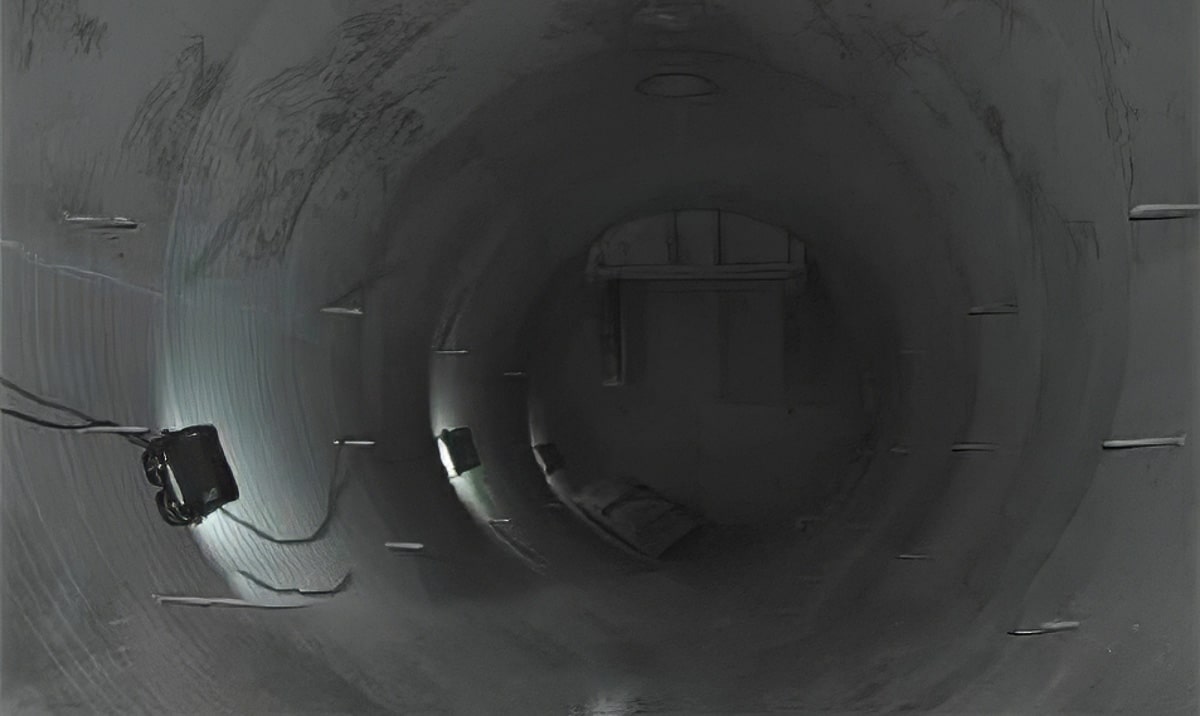

After two and four year operational intervals, all thermal sprayed surfaces were carefully visually inspected for signs of corrosion in blisters or delamination. A visual inspection of nozzles was conducted with a borescope. No failure indications were identified.

High-performance HVTS cladding delivered in tandem with precision bore welds

Large heavy walled vessels on offshore production facilities are very difficult to replace or effectively repair over large surface areas.

IGS mobilized a multi-discipline project team to execute the repair. All internal surfaces of the slug catchers were clad using IGS HVTS technology. Simultaneously, small-bore nozzles (8” and below) were protected using automated bore welding techniques due to access limitations for thermal spray.

To ensure full compliance with offshore safety and metallurgy standards:

• Weld procedures were optimized to avoid heat input through the 316SS-tocarbon steel transition, eliminating the need for PWHT.

• Special masking was applied to flange faces and gasket contact points to protect sealing surfaces during application.

• All activities were executed with the platform live and under strict work permit controls.

Each vessel was completed within the scheduled turnaround, without extension, and with minimal disruption to surrounding operations.

Follow-on success and future offshore applications

Following the success of this dual-vessel project, IGS has been re-engaged by the client for similar offshore asset applications. The reliability of the solution and its fit-for-purpose execution in a live offshore environment have positioned IGS as a trusted long-term partner for critical asset protection offshore.

Related Case Studies:

- Rectifying Failed Thermal Spray Corrosion Protection

- Prevent Corrosion due to a Change in Operating Process in a Fractionation Column

- A Short-term Saving has a Long-term Cost!

- IGS ClearStream Chromium-6 Filtration for Safe HVTS Application

- Caustic Vessel Protected After Repeated Failure

- H2S Corrosion in an Upstream Separator Vessel Permanently Stopped

- Emergency Response: Localized Corrosion in a Fractionation Column

- Severe Amine Column Corrosion Permanently Frozen

- HVTS Stops Sour Water Stripper Corrosion

On-site Thermal Spray Coating Services from IGS:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.