Primary Reformer Hot Spot Repair

Refractory Issue in a Primary Reformer

A prominent fertilizer manufacturer based in Qatar has partnered with IGS to prevent an unplanned shutdown of one of their trains. The project focused on addressing the critical issue of reformer hot spot repair in the gas duct area of the third ammonia production train.

Fertilizer Plant Overview

Asset Owner: Leading fertilizer manufacturer in Qatar

Operations: Six trains in ammonia and urea production

Challenge: Hot spot identified in Ammonia train 3, necessitating urgent repair

Reformer Hot Spot Issue in Ammonia Train 3

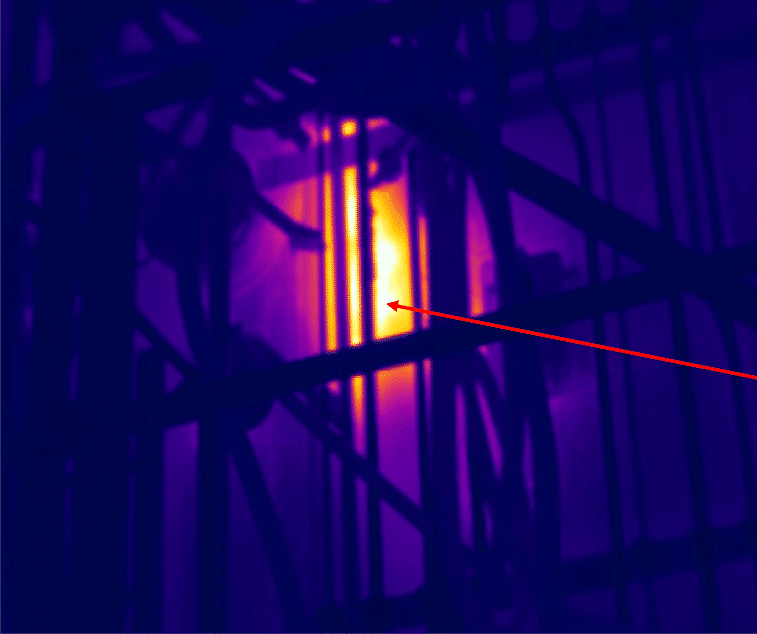

The hot spot in the reformer duct area of Ammonia train 3 posed a significant threat, potentially leading to an emergency shutdown if not addressed promptly. The reformer hot spot area started to crack. The initial attempt at repair involved welding a patch plate, but this proved insufficient, leading to further complications. After a few months, the weld between the original substrate and the new alloy plate also started to fail, causing more cracking.

Evaluation of Alternatives

The plant could repair the hot spot offline by isolating the train, but that option would prove costly. The plant would have faced a minimum two-week shutdown. The economic impact of avoiding such a shutdown is substantial. Another alternative would be to repair the hot spot on a live reformer during its normal operation. Such repair requires expertise and equipment not typically possessed by general contractors. As a result, the plant reached out to IGS, an efficiency and reliability solutions provider.

Reformer Hot Spot Repair Deployment and Mobilization

IGS, leveraging the Hot-Tek Hot Refractory Repair (HRR) technology, swiftly mobilized to address the hot spot. Notably, the foresighted decision to establish a workshop for equipment and materials in the region proved instrumental. The team executed the repair on a live reformer in nine shifts, ensuring no disruption to plant operations.

Extended Maintenance Window

Due to the effective reformer hot spot repair, the plant extended the maintenance window, deferring the shutdown for another year. This decision was influenced by the elimination of the hot spot and the observed superior performance of the newly installed refractory.

Plant Manager Feedback

“The entire plant management witnessed the installation process, appreciating the innovative approach that averted a potential shutdown. We even hosted a small celebration at the end of the project.”

Successful Reformer Hot Spot Repair Prevents a Shutdown

The collaboration between IGS and the fertilizer manufacturer exemplifies the effectiveness of the Hot-tek HRR technology in mitigating critical hot spot issues. The successful repair prevented a costly shutdown an demonstrated the long-term benefits of IGS solutions.

Hot-tek Services from IGS:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.