Midstream Amine Still Corrosion Permanent Repair

During a turnaround inspection at one of P66 gas treating facilities in Giddings, TX, severe corrosion damage was discovered in the main amine still tower between trays 13 and 18. The damage was caused by amine attack on the carbon steel shell.

Previous Mitigation Attempts

In the past, P66 had relied on weld buildup on an as-needed basis to address the corrosion and maintain minimum thickness requirements. They also applied organic coatings on a 5-year turnaround cycle. However, the organic coating was failing prematurely, and the recurring repairs were proving to be ineffective and costly.

Evaluation of Alternatives

Several coating options were explored but none provided guaranteed protection to the vessel. They were either good for the amine exposure or the temperature but not both. Following a consultation with the refining side of the business, IGS HVTS high alloy cladding was proposed as a solution due to its excellent performance in the amine units across P66 refineries and additional global references from similar facilities.

HVTS Solution

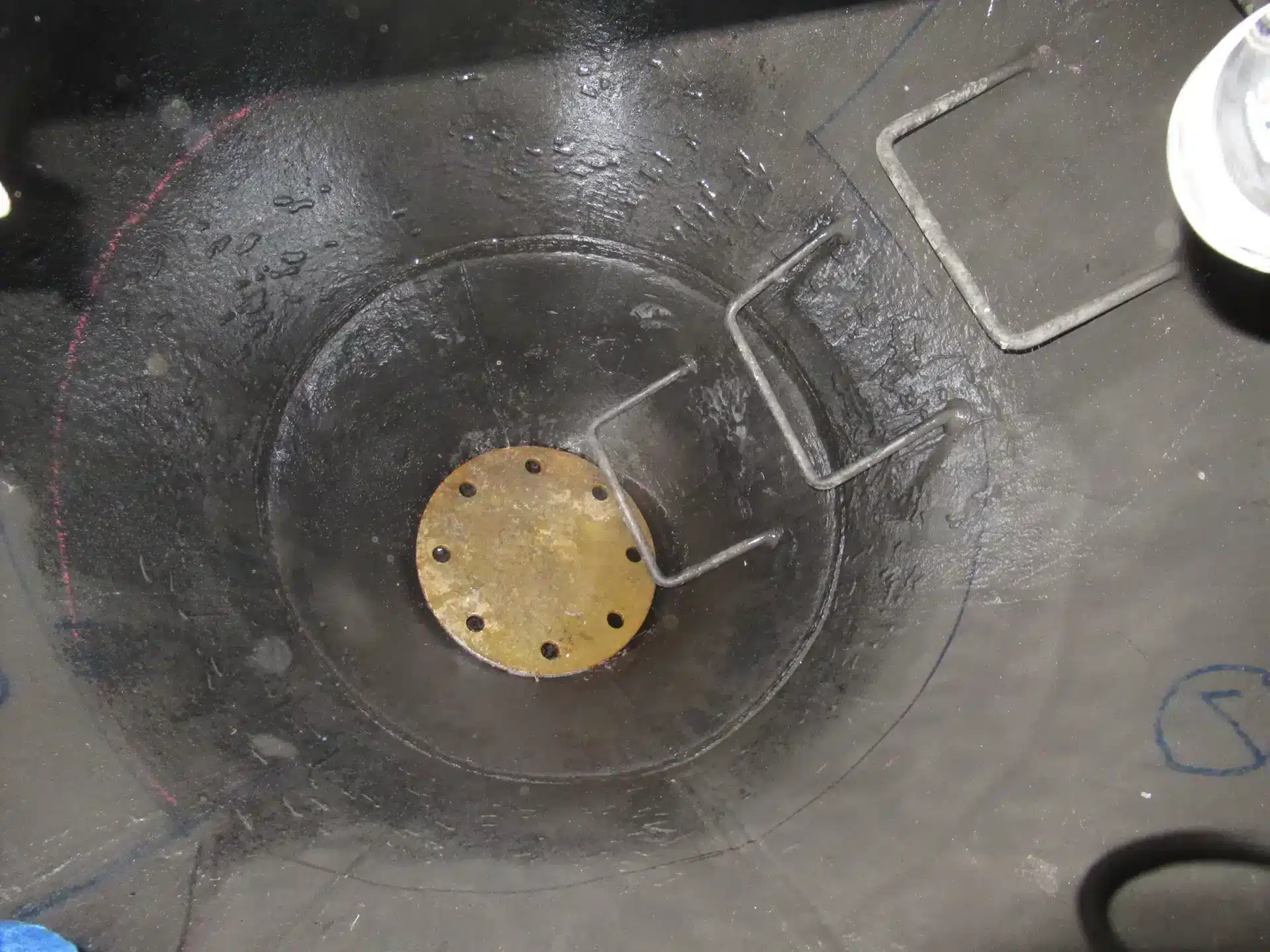

Seeking a permanent repair solution, P66 reached out to Integrated Global Services (IGS) for their High Velocity Thermal Spray (HVTS) technology. IGS responded quickly, sending a site superintendent to assist with surface preparation, scaffolding requirements, and site support items just two days after the initial call.

The HVTS application covered 277 square feet and was completed in 5 shifts. The process does not introduce any heat-affected zones and as a result does not require post-weld heat treatment, minimizing downtime and maximizing efficiency.

Key Benefits of the IGS HVTS Cladding Solution

- High-Temperature Resistance: With its ability to withstand high temperatures, the HVTS cladding proved to be an ideal solution for the harsh operating conditions of the amine still.

- Comprehensive Coverage: By cladding the entire damaged surface area of the still, IGS ensured comprehensive protection against corrosion, eliminating the need for spot welding or reapplying organic coatings that were prone to failure.

- Efficient Turnaround Execution: IGS’s prompt mobilization and efficient project execution ensured that the scope was completed within the planned TAR window, minimizing downtime and associated costs.

Results

By choosing HVTS over traditional weld overlay and organics, P66 expects to eliminate the need for recurring repairs in this problem area for the lifetime of the asset. The HVTS solution is a permanent repair, reducing the total cost of ownership and eliminating future maintenance requirements. The successful application of HVTS at the Giddings facility has demonstrated the technology’s effectiveness in amine service environments.

Conclusion

IGS’s rapid response and the successful implementation of HVTS technology has provided P66 with a long-term solution for their amine still corrosion issues. By investing in this advanced repair method, P66 has taken a proactive step in extending the life of their asset, reducing maintenance costs, and minimizing future downtime.

Next Inspection

IGS will physically enter the vessel during their next shutdown in 5 years and perform visual inspection, as well as take thickness readings to compare to the as-applied thickness map to ensure cladding integrity.

HVTS™ Technology Advantages

- Proprietary Superalloy Cladding: IGS’s patented HVTS™ material was specifically designed for high-temperature environments and validated through multi-year testing in collaboration with OEMs.

- High Velocity Thermal Spray (HVTS): The technology ensures dense, impermeable cladding with minimal stress on the substrate material.

- Custom Protective Isolation Tooling: Designed to shield areas not being treated and maintain critical tolerances during application.

Related Case Studies:

- Ethylene Quench Tower Corrosion Mitigation Saves $1.8Mil

- Cracker Quench Column Corrosion Stopped with IGS HVTS Cladding

- A Short-term Saving has a Long-term Cost!

- Column Shell Corrosion Protection Verified

HVTS Prevents Corrosion Attack in a Regenerator Column at LNG Plant

Severe Amine Column Corrosion Permanently Frozen

Related Article:

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.