Ammonia Reformer Hot Spot Repair During Operation

Fertilizer Plant Overview

This project took place at a major U.S. fertilizer manufacturer producing a diverse range of products including:

- Anhydrous ammonia

- Urea and urea blends

- Ammonium nitrate solution

- Phosphate and potash

- Ammonium polyphosphate

- Sulfur-based products

The Challenge – Preventing an Unplanned Shutdown of an Ammonia Reformer

The plant faced a critical maintenance challenge when a significant hot spot developed on their ammonia reformer’s external steel shell at a former manway location.

Refractory maintenance and repairs are typically undertaken during planned shutdowns. If this refractory failure resulted in an unplanned shutdown, it could have cost the plant more than $1m/day in lost production.

Other challenges included:

- Operating conditions included bridgewall temperatures of approximately 1850°F (1010oC)

- Complete failure of 7-inch refractory lining

- Visible steel distortion due to excessive temperatures

SMR Refractory Anchor Failure Mechanism

Refractory anchor failure often occurs due to corrosion of the welded joint between the anchor and the external steel shell of the fired heater. This failure mechanism typically involves:

- Hot flue gases penetrating through the refractory lining.

- Condensation of these gases upon reaching the cooler shell.

- Rapid oxidation or corrosion of the weakest point, which is usually the weld.

Once the anchor support is compromised, individual refractory components such as bricks or modules can fall away, exposing the metal shell. This creates a domino effect, leading to the failure of adjacent refractory lining.

Initial Hot Spot Repair Attempt

The plant personnel attempted to repair this area on their own by installing a steel box over the affected area and filling it with castable refractory.

This temporary solution failed within two weeks, highlighting the need for a more robust approach. Facing the prospect of an expensive emergency shutdown, plant management sought expertise from Integrated Global Services (IGS).

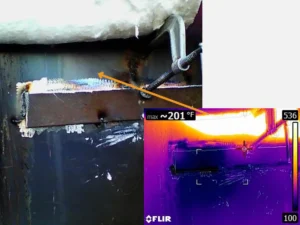

Steel distortion due to high temperatures

Live SMR Repair Solution Implementation

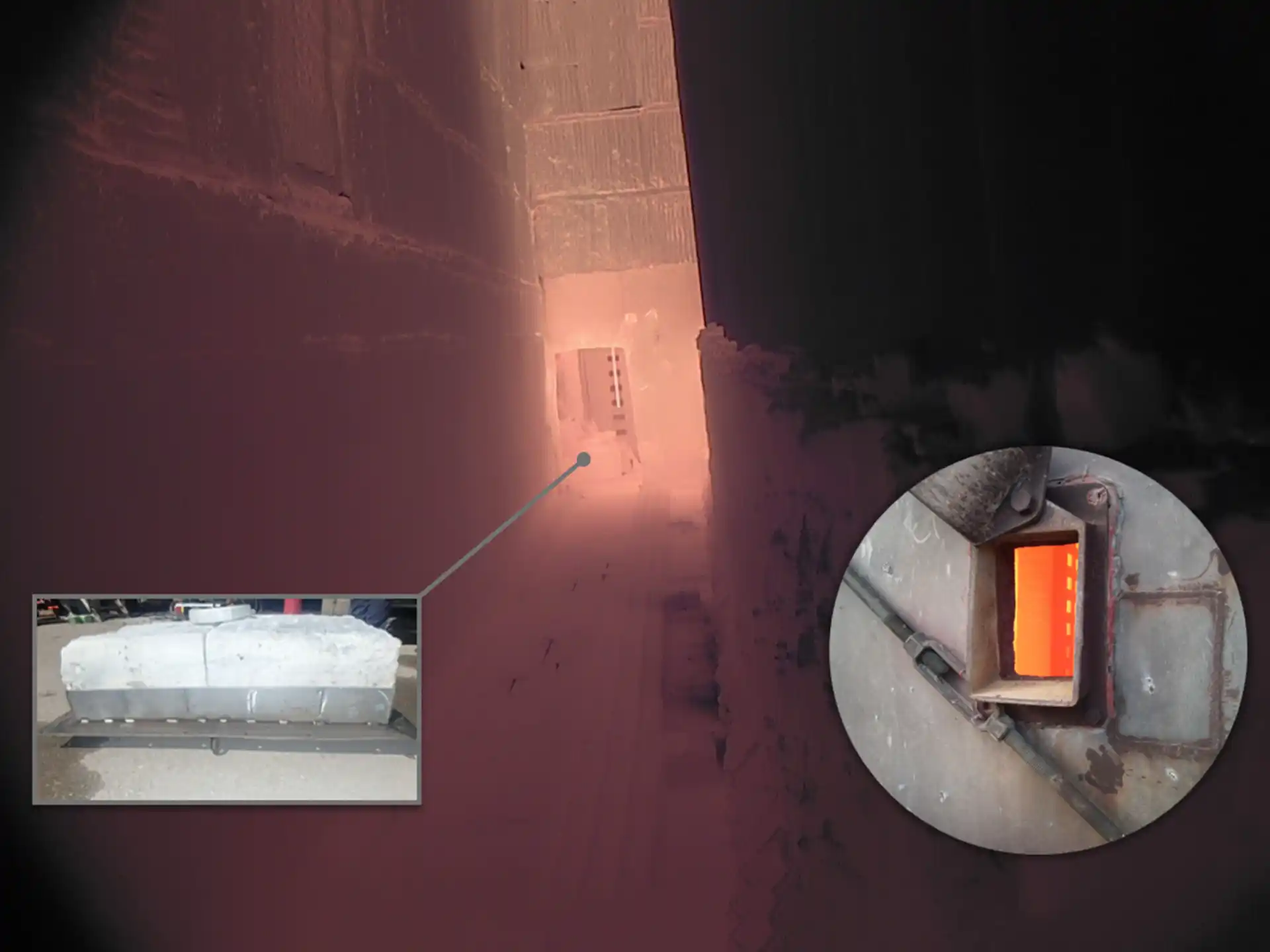

IGS deployed its proprietary Hot-tek Hot Refractory Repair (HRR) service, which enabled repairs during normal operations. The repair process involved several steps:

- Creation of access points under negative pressure

- Installation of protective refractory to shield workers from radiant heat

- Installation of hot refractory baskets flush with existing refractory

- Management of structural hazards, including careful handling of an exposed structural beam

Access creation under negative pressure

Hot refractory baskets installed

Key Technical Achievements

The project was successfully completed in three days, maintaining full operational capacity throughout the repair.

The solution resulted in reduced temperature in the primary repair area from over 536°F (280oC) to under 100°F (37oC).

IGS successfully addressed a second identified hot spot, bringing temperatures down from over 500°F (260oC) to 70°F (21oC).

Repaired area is altered from over 536°F (280oC) to under 100°F (37oC)

Economic Impact

- The solution provided significant cost savings by:

- Avoiding production losses from emergency shutdown

- Maintaining full operational capacity

- Extending equipment lifespan

- Reducing energy waste from heat loss

Plant Management Response

The plant manager extremely pleased with the results, particularly noting the elimination of an emergency shutdown risk and the maintenance of production continuity.

Fast Solutions to Hot Problems

Hot spots resulting from damaged refractory, scaled or misaligned process tubes, plugged SCR catalyst banks, and fouled convection sections can all affect the performance, reliability and safe operation and ultimately the operating capacity of the fired heater.

If a planned shutdown is still years away, maintenance managers are faced with a dilemma. To accept the risks and inferior performance or attempt temporary repairs, potentially still risking an unplanned shutdown if the solution is not fit-for-purpose.

Refineries, Petrochemical and Agrochemical Plants rely on the Hot-tek service, delivered by Integrated Global Services (IGS) to effectively address fired heater maintenance challenges in between turnarounds, without the need to shut down or power down their fired heaters.

Each service has been designed and perfected in collaboration with major oil and gas refineries to ensure that the safety, performance, and the output of the fired heater is not compromised.