Ethylene Quench Towers

Prevent Ethylene Quench Tower Corrosion with On-Site HVTS® Cladding

Ethylene quench towers experience some of the highest failure rates in fractional distillation. These towers consolidate numerous distillation challenges into a single vessel, including high temperatures, solids, fouling, oxygenates, polymerization potential, and a mixture of hydrogen, steam, and C1 to C20 hydrocarbons.

Ethylene Quench Tower Corrosion

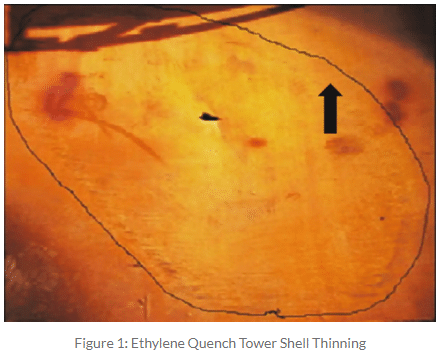

The primary role of the water quench column is to cool the cracker effluent to a temperature suitable for compression. Following their exit from the secondary transfer line heat exchangers, the high-temperature cracked gases are cooled to their adiabatic saturation point by vaporizing circulating bottom quench water. Here, most tar, coke, and heavy hydrocarbons condense. Inside the quench tower, the falling water droplets encounter the upward-flowing gas stream, leading to continuous particle bombardment. This process gradually thins, cracks, and erodes the quench column shell, often resulting in erosion-corrosion failure (1).

(1) A. Goswamia, S. Kumarb. Failure of water quench tower in an ethylene cracking plant

Water Stripper Pitting in your Quench Tower

In the water stripper, pitting corrosion and steam erosion contribute to reduced shell and cone thickness. This general acidic attack indicates that condensate forms below it, with acid gases like H2S and CO2 create aqueous phase acids on the substrate surface.

How can IGS help?

IGS is a global company specializing on in-situ corrosion prevention. Every year we protect hundreds of vessels with impermeable high-alloy cladding. We provide turn-key project execution, encompassing surface preparation, cladding application, and stringent quality control.

On-Site Corrosion Prevention in Quench Towers

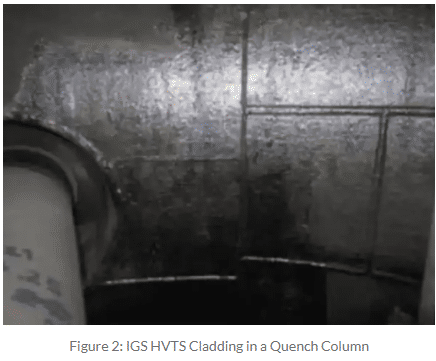

Integrated Global Services (IGS) addresses quench tower corrosion with an on-site alloy upgrade.

Our bespoke High Velocity Thermal Spray (HVTS®) cladding technology and material do not heat the surface above 120 °C during application, preventing distortion and eliminating the need for post-weld heat treatment. Boasting higher erosion and corrosion resistance than the base metal, our cladding provides a highly erosion-resistant sacrificial barrier.

While erosion as a process cannot be entirely halted, IGS cladding effectively protects the substrate from the erosive environment and prevents erosion from progressing to pressure boundary wastage or failure in ethylene quench towers.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.