IRIS inspection and fouling removal for gas coolers at an offshore platform in Nigeria

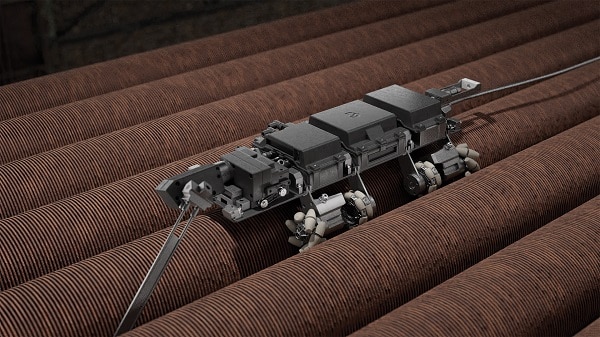

This project marked the first full IRIS integrity assessment and fouling removal campaign since the unit was commissioned three years earlier. TubeTech™ was awarded the contract based on its proven ability to remove fouling from offshore heat exchangers and specialist small-bore tubes, delivering inspection-ready results for FPSO operations.

TubeTech restored and enabled IRIS inspection across multiple gas coolers, including Koch/Brown fin tube units, onboard one of the largest Floating Production Storage and Offloading (FPSO) vessels operating offshore Nigeria. The work was executed within a tightly constrained turnaround (TAR) window and under challenging offshore environmental conditions.

Access, safety, and coordination challenges in a complex offshore TAR environment

The project presented a range of logistical and technical challenges that demanded precise planning and execution:

-

A very tight timeline to transport both cleaning equipment and crew offshore to the FPSO.

-

A 120-meter setup distance between the diesel-driven equipment and the workface, requiring hose routes to be carefully routed around live plant trains to mitigate operational risk.

-

Cleaning of micro-bore offshore exchanger tubes with small internal diameters.

-

Gas cooler restoration and inspection conducted directly beneath the FPSO flare stack, where elevated temperatures created safety and personnel risk.

-

Severely limited working area due to other TAR operations, requiring continuous coordination with scaffold teams, riggers, and fitters to maintain schedule adherence and avoid disruption.

These conditions eliminated many conventional cleaning methods and required a partner with proven offshore turnaround (TAR) expertise in constrained-access fouling removal and multi-disciplinary coordination.

Precision fouling removal and successful IRIS inspection without rigid tooling or high pressure

TubeTech deployed engineered unblocking techniques and specialized polishing heads to safely remove coke and fouling deposits from internal surfaces of the gas cooler and Twisted Tube exchangers. These advanced methods enabled thorough cleaning without excessive pressure or rigid semi-automated tooling, minimizing risk to delicate tubes.

Cleaning finished on schedule with no rework. IRIS standards were achieved on the first attempt, confirming both cleaning quality and tube integrity. The results validated TubeTech’s reliability in restoring offshore gas coolers and heat exchangers to inspection readiness under challenging FPSO TAR conditions.

Two offshore assets restored to inspection standard with zero safety incidents

The project delivered on all critical objectives:

-

Inspection readiness restored for both gas coolers.

-

Integrity confirmed through successful IRIS testing after cleaning.

-

No tube damage, no safety incidents, and zero schedule overruns.

-

Seamless coordination across all TAR disciplines.

The client commended IGS for its professionalism, noting that all equipment was certified and fit-for-purpose, all documentation was readily available, and all work was completed safely and on schedule.

This successful offshore inspection and cleaning campaign further reinforced IGS’s reputation for delivering safe, efficient, and high-quality results for FPSO maintenance programs.

“With so many different disciplines operating in a very tight area, the client was amazed at how effectively our team integrated with the wider TAR personnel, enabling each group to work safely and efficiently. This was an extremely challenging contract that evolved day by day, but we executed it within the tight timeframe and delivered exactly to the client’s specifications.”

— Scott Donson, VP – TubeTech Technologies, IGS

A foundation for future offshore TAR success

By restoring two critical assets to inspection-ready condition within a constrained TAR window, IGS strengthened its role as a trusted offshore reliability and maintenance partner. The success of this dual-exchanger project has paved the way for future collaboration across upcoming TARs on this and other offshore production assets.

Complex offshore exchanger types cleaned and restored to inspection standard, safely, on time, and with zero disruption.

That’s Asset Vitality.

Related Case Studies:

- TubeTech™ Restores Offshore Crude Oil Heaters

- Offshore Slug Catcher Corrosion Mitigation Saves $7.78M

- SS Chloride Stress Corrosion Cracking in Critical Process Assets

- Mitigating Chloride Stress Corrosion Cracking (CSCC) in Offshore Condensate Strippers

- Rectifying Failed Thermal Spray Corrosion Protection

- Prevent Corrosion due to a Change in Operating Process in a Fractionation Column

- A Short-term Saving has a Long-term Cost!

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.