Hot-tek Applications in Steam Methane Reformers

Understanding Steam Methane Reforming (SMR)

Steam Methane Reforming (SMR) is a process for producing syngas (a mixture of hydrogen and carbon monoxide) by reacting methane with steam. This process is commonly used for hydrogen production, but syngas can also be used to manufacture ammonia or methanol.

SMR is an endothermic reaction, meaning it requires heat to proceed. It is typically operated at high temperatures and moderate pressures. The high temperatures and long production runs between scheduled turnarounds create opportunities for IGS Hot-tek online inspections, maintenance, and repairs. These unique services provide valuable solutions to operators with no impact on production.

Hot-tek Services for SMR Applications

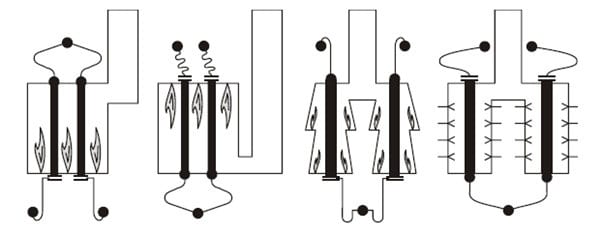

Hot Refractory Repair

Hot-tek Hot Refractory Repair services are frequently used in SMR applications, especially in:

- Hydrogen production facilities

- Primary reformers in ammonia production for fertilizer facilities

Case Study: Ammonia Reformer Hot Spot Repair During Operation

We successfully implemented Hot Refractory Repair at a fertilizer facility, allowing the customer to extend production for a full additional year until their scheduled shutdown.

Hot Inspection Service

Hot-tek Hot Inspection Service employs the proprietary Lancescope™ technology to:

- Discover the scope of refractory problems

- Observe the actual Hot Refractory Repair process

- Provide final examination of repair results

This service ensures thorough assessment and quality control for all our hot repairs.

Hot Convection Cleaning

In SMR units, the convection section duty is essential to the processing balance. If fouling becomes an issue during a production run, it can lead to:

- Decreased throughput

- Potential unscheduled shutdown

IGS Hot-tek Hot Convection Cleaning service allows a return to desired production rates by removing processing bottlenecks.

Hot Vacuuming Service

Many SMR units have SCR (Selective Catalytic Reduction) additions to control NOx emissions, where flue gases are treated to reduce emissions effectively.

During operation, the ceramic catalyst’s upstream face can become fouled with dust and fiber originating primarily from the radiant section of the reformer.

IGS Hot-tek Hot Vacuuming Service efficiently cleans the face of catalyst panels, returning SCR efficiency to a like-new condition.

Testimonial

“Hot-tek’s emergency refractory repair extended our production run by a full year, saving us over $4.2 million in avoided shutdown costs.”

Operations Manager, Leading Fertilizer Producer

Global Availability

IGS Hot-tek services are available worldwide with rapid deployment capabilities to meet urgent SMR maintenance needs:

- Emergency response teams

- Operations in over 30 countries across 6 continents

- More than 3,000 successful projects completed globally

Our global network of technicians and engineers ensures prompt service delivery regardless of your facility’s location. With strategically positioned teams around the world, we minimize response times and maximize uptime for your critical SMR operations.

IGS Hot-tek’s international experience includes successful projects in diverse operating environments, from extreme cold to desert heat, ensuring that whatever your operational challenges, our solutions are field-proven and reliable.

Schedule Your No-obligation Hot-tek Consultation Today

Our specialized team will assess your SMR efficiency and challenges to develop a customized maintenance plan to keep your plant running at peak performance.

Contact our experts now:

+1 (888) 506 2669