Boiler Tube Coating

Boiler Tube Coatings for CFB, PC-Fired, BFB, and Grate Boilers

Preventing Boiler Tube Corrosion

Tubes are a critical component of your plant’s boiler system. That’s why IGS has developed a proprietary High Velocity Thermal Spray (HVTS®) which can be applied to grate-fired WtE (EfW) boiler tubes to protect them from corrosion, erosion, and slagging.

HVTS® is a high-alloy corrosion-resistant cladding and provides excellent value and results for improving your boiler system reliability and longevity at a fraction of the cost and time of weld overlay.

IGS leverages decades of experience with more than 500 boiler reliability applications. We are at the forefront of maximizing run time while minimizing outage frequency and cost. Plants worldwide partner with IGS for a turnkey solution to protect boiler tubes from fly ash erosion and fireside corrosion.

Read more: Causes of Boiler Corrosion and Benefits of Boiler Tube Coating

SMART Solution for Boiler Reliability

- Systematic Approach to Boiler Reliability

- Materials and Equipment Engineered for Specific Results

- Applications by Trained and Certified Teams

- Results are Measured, Documented, and Monitored

- Testimonials Prove Performance!

Systematic Approach to Boiler Reliability

We understand the wear patterns and problem areas in the boiler by investigating the following:

- Capture all boiler specific information; year commissioned, size, fuel blend, nominal thickness, and previous UT data, among others

- Understand maintenance and operational philosophy

- Consider past tube failures, type, and locations

- Consider past solutions

- Consider trends, and wear occurrences that differ

- Document with images while accurately noting location

- Inspection and thickness mapping of existing cladding (if any), taking three readings looking out for preferential corrosion of the boiler tube

Boiler Tube Coating Vs. Cladding to prevent corrosion – What is the difference?

While applied using a similar method to more traditional thermal spray coatings, the performance of High Velocity Thermal Spray (HVTS®) goes beyond the usual expectations of a spray coating in reducing corrosion in boiler tubes. Therefore, to help customers differentiate, we refer to our HVTS®solution as a thermal spray cladding.

What causes the failure of boiler tubes?

Boiler tubes fail for many reasons. On waterwalls, wall thinning is most likely caused by corrosion or erosion. Superheaters could have coal ash corrosion or problems related to Cr depletion and carburization. Sootblower, watercannon or hydrojet cannons can cause erosion and cracking problems as well.

The most common cause of tube failure, according to EPRI, is fireside corrosion.

What causes corrosion in boiler tubes?

Three primary mechanisms for fireside corrosion are sulfidation by iron sulfides (pyrites), gaseous corrosion by hydrogen sulfide, and corrosion by alkali chlorides produced from gaseous hydrogen chloride. All of these occur in reducing or alternating reducing/oxidizing conditions. Homogeneous and dense High Velocity Thermal Spray (HVTS®) cladding performs well in protecting the tubes.

What is the impact of boiler tube corrosion?

Boiler corrosion can happen for many reasons, such as improper and unscheduled maintenance, or when oxygen is present in the boiler water. When this happens, disadvantages may include lost efficiency, a shorter system lifespan, higher costs, leaks, pitting and more. All of these lead to a cost in time, money and resources if not prevented with boiler tube coating.

Corrosion Resistant Boiler Tube Coatings in the Market

Refractory was the first protection against corrosive flue gases in boiler tubes, but limited heat exchange properties cut thermal efficiency. Refractory alloys can be used but due to the excessive cost of such material the main material used for building boiler is carbon steel or low alloyed steel. The implementation of a surface protection layer is the most cost-effective solution. Even a thin layer can deliver significant improvement on corrosion resistance.

The use of ceramic coatings seems an attractive approach, however, the thermal expansion mismatch and the fragility of such a coating makes it unreliable. Ceramic coatings are more likely to crack than thermal spray coatings, or cladding, and corrosion can develop underneath the protective layer which can peel off, leaving little protection.

Corrosion Resistant HVTS® Metalspray®

The benefit of High Velocity Thermal Spray is the application of a thin layer of material without dilution and heat-affected zone (HAZ).

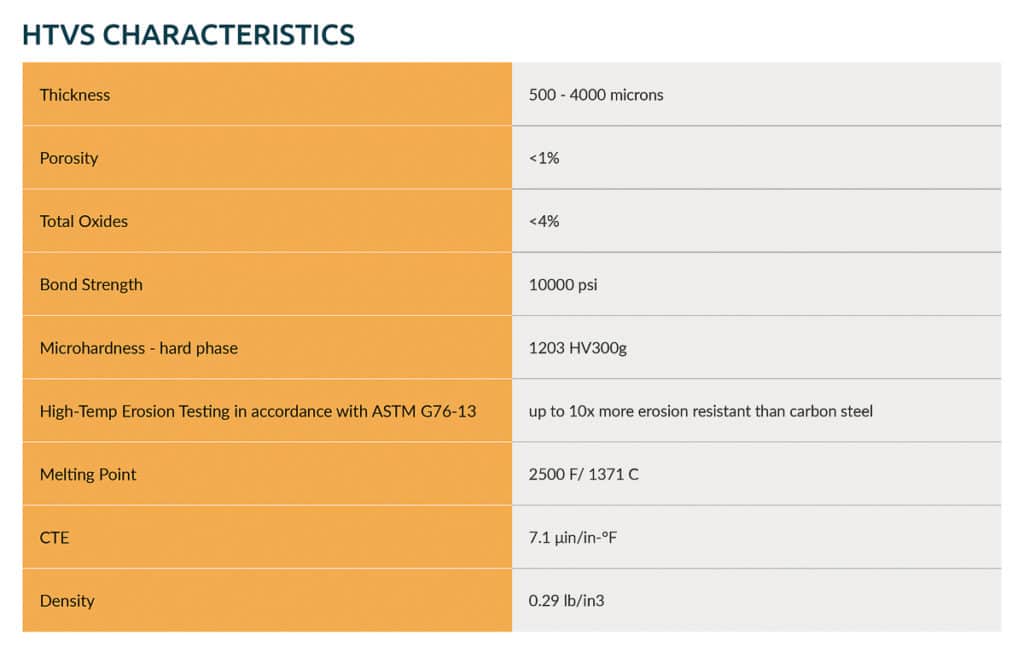

IGS HVTS® processes ensure finely structured cladding, with an order of magnitude, lower permeability and greater homogeneity. Changes in feedstock chemistry have further improved performance by significantly reducing stress, increasing bond strength, and mitigating oxide content. By addressing the root cause of these microstructural defects through the process and material chemistry, HVTS® can be successfully employed in the field. We work during shutdowns, with high production rates and low costs. As with welding and other cladding technologies, surface preparation, material, process, and procedure criteria are defined in specifications. HVTS® generates no Heat Affected Zone on the pressure parts and does not place residual stresses on the base metal since the temperature of the base metal remains low even without water in the boiler tubes.

IGS On-Site Thermal Spray Cladding

Integrated Global Services provides on-site thermal spray cladding inside CFB, PC-Fired, BFB, and Grate Boilers in the European Union, including UK, Germany, Netherlands, Sweden, and France, from our operations center in the Czech Republic. Being an international company, we clad in the United States, Middle East, Japan, South-East Asia, and Africa.

The IGS HVTS® systems demonstrate excellent corrosion resistance with little or no indications of metal loss in extreme conditions of waste incinerators and refuse-derived fuel (RDF) grate-fired boilers. Whereas, 625 weld-overlaid components must be replaced at end of life, IGS HVTS® can be reliably refurbished or even replaced in-situ without replacing the underlying component. The corrosion resistance coupled with the ease of application in-situ makes the selection of such IGS claddings favorable in areas where weld alloy 625 fails.

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.