Reducing Emissions in Fired Heaters

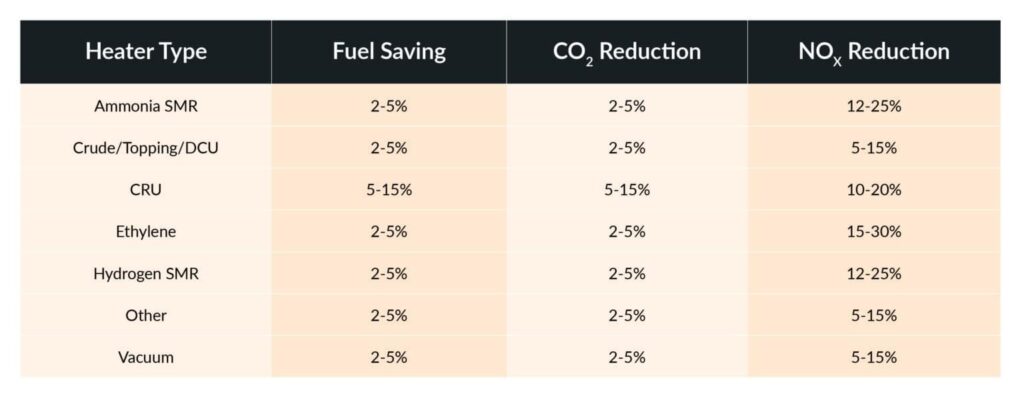

Refineries, petrochemical and chemical facilities can reduce NOₓ by up to 25% and CO₂ by up to 15%.

Oil refineries, petrochemical and chemical facilities are widely considered as some of the main sources of nitrogen oxides (NOₓ), and carbon dioxide (CO₂) emissions which adversely affect the environment.

Improving Performance of Fired Heaters and Reformers to Reduce Environmental Emissions

Advanced performance enhancing solutions have created an increased opportunity to reduce emissions in fired heaters and reformers. IGS is working with ESG committees across the globe to help reduce emissions of both NOₓ and CO₂, contributing to total emissions reduction across facilities worldwide.

How to Cut Emissions & Fuel and Increase Capacity in Fired Heaters

Expected Emissions Reduction with IGS Fired Heater Services are:

How Refineries Achieve Emissions Reduction with IGS’s Engineered Solutions

Refineries, petrochemical and chemical facilities work with Integrated Global Services (IGS) to evaluate their fired heater. The evaluation estimates results that can be achieved with the application of one or several innovative technologies: high emissivity Cetek coatings, TubeTech™ cleaning services, and Environmental SCR solutions.

Cetek coating can be applied into the refractory, process tubes, or both, depending on the type of the fired heater and its design and operating parameters.

I’m here to help

Larry Emch

IGS Subject Matter Expert

IGS Reduces Fuel Consumption and Emissions in Fired Heaters

Radiant Section Coatings

Process tubes in fired heaters are typically steel alloy, such as ASTM A335 P9 (9% chrome). In use at high operating temperatures, in the presence of excess oxygen, the external surfaces will oxidize, and layers of scale will grow. These layers are very insulating and create a significant barrier to conductive heat transfer to the process fluid inside.

This leads to over-firing the heater to maintain production, but that creates more oxidation and scale growth. Ultimately, the fired heater becomes limited and production rates suffer.

The tube coating application process removes all the scale and oxidation from the tube surfaces. A thin film, high emissivity ceramic coating is then applied, which prevents any further oxidation and scale growth for the life of the coating. The high emissivity nature of the coating ensures that a maximum amount of radiant heat available is absorbed by the tube surfaces.

The combined benefit from high emissivity coatings applied to refractory and tube surfaces can be as high as 15% increase in radiant section heat transfer efficiency.

Convection Section Cleaning

Convection section efficiency can be improved with the use of convection section cleaning. IGS’ TubeTech™ solution utilizes robotic cleaning that achieves a 90%+ clean area with no risks associated with manual/man entry cleaning.

Why is Fired Heater Efficiency Important?

Improving the efficiency of the Radiant and/or Convection section of the fired heater leads to a decrease in fuel consumption (unless a capacity increase was the original objective). A decrease in fuel consumption translates into lower CO₂ and NOₓ emissions.

Case Study: Tüpraş Izmir Refinery

Overview

- The average cost of hydrogen production before and after cleaning was calculated at $943.9-919.3 $/t. The production cost of hydrogen decreased by $24.6/t after cleaning and the payback period for the project was less than 60 days.

- The average flue gas temperature decreased from 278°C before cleaning to 220°C after cleaning, meaning that the furnace’s thermal efficiency increased by approximately 3%.

- Steam production increased by approximately 20%, and the generated steam temperature increased by 10°C-15°C.

How can IGS help reduce your emissions?

The Science Behind the Solution

Refractory Surface Emissivity: Why does it Matter?

In the radiant section, or primary reformer, much of the radiant energy from the flame/flue gases is transferred directly to the process/catalyst tubes; however, a significant proportion interacts with the refractory surfaces.

The mechanism of this interaction has an appreciable effect on the overall efficiency of radiant heat transfer. A major factor in determining the radiant efficiency is the emissivity of the refractory surface.

At process heater operating temperatures, new ceramic fiber linings, for example, have emissivity values of around 0.4. Insulating fire brick (IFB) and castable materials have emissivity values around 0.6. These materials have been designed with structural considerations and insulating efficiency as the primary requirements.

They tend not to handle radiation in the most efficient way. Cetek Ceramic Coatings, however, with emissivity values of above 0.9, have been designed specifically to supplement the radiation characteristics of the refractory surfaces.

It is important to understand how the emissivity property of a surface can affect the efficiency of heat transfer. There are two factors which need to be taken into account. The first is the spectral distribution of the radiation absorbed/emitted from a particular surface and the second is the value of the emissivity of that surface.

This increase in heat transfer efficiency leads to two significant effects on NOₓ and CO₂ emissions:

- Lower flue gas temperature leaving the radiant section (bridgewall temperature), since more of the available heat is absorbed by the process tubes in the radiant section. In higher temperature processes, such as Catalytic Reforming, Steam Methane Reforming and Steam Cracking, the NOₓ emission reduction has been found to be as high as 25-30%.

- The increase in radiant section heat transfer efficiency means that the same absorbed duty may be achieved from the use of less hydrocarbon fuel, which could lead to 15% reduction in CO₂ emissions.

What is Thermal NOx?

In high temperature, gas-fired process heaters, including refinery fired heaters, steam methane reformers and steam crackers, the NOx emissions are mostly from Thermal NOₓ. These are formed when nitrogen and oxygen in the combustion air combine at the high temperatures in flame combustion products.

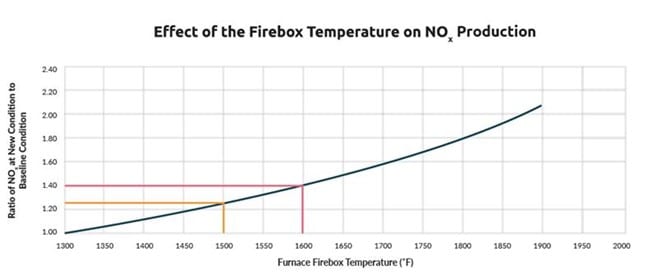

Effect of the Firebox Temperature on NOₓ Production

The relationship between firebox temperature and NOₓ emission is shown in the chart below, which is extracted from API Standard 535.

What are CO₂ Emissions?

CO₂ emissions are derived solely from burning hydrocarbon fuels – natural gas, or refinery derived gas. Any reduction in hydrocarbon fuel usage will naturally result in lowering the CO₂ emissions from that fired heater.

The amount of heat, Q, radiated from a surface (area, A; temperature, T; emissivity, ε) is given by the following, well-known Stephan Bolzmann equation:

Q = AεσT4

Where σ is the Stephan Bolzmann constant.

Lobo & Evans and others extended the calculation with reference to fired heaters and a simplified equation would appear as:

QR = Aσ(T14-T24)/F

Where F = 1/ε1+{A1/A2}{(1/ε2)-1} for tubes of area A2, surface temperature T2 and emissivity ε2 which are inside an enclosure, area A1, with surface temperature T1 and emissivity ε1.

The effects of maximizing the emissivity ε1 of the enclosure are obvious; there is a significant increase in radiant heat transfer to the tubes.

Free Consultation with IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.