Integrated Global Services Cracks the Code with Biomass Corrosion Resistant Thermal Spray Cladding

European countries lead the wave of Biomass energy. While some operators build new biomass-fired boilers, others retrofit old coal-fired units to burn biomass. Although this is a more environmentally friendly fuel, related Alkali- and Sulfide-induced corrosion of boiler tubes has become a problem. Integrated Global Services (IGS) Inc. developed and field-tested a new metal alloy to cope with both corrosion and erosion in these aggressive environments. Recent, flawless results have shown that the high velocity thermal spray (HVTS) cladding in a large E.ON Biomass boiler in Sweden has delivered the desired benefit of lower operational expenses.

Integrated Global Services (IGS) is an international company with a 35+year history in providing on-site corrosion protection for power boilers, oil and gas pressurized vessels, and heat recovery boilers. IGS surface protection solutions have been applied to 2,500 industrial boilers worldwide. Over 500 of these are Circulating Fluidised Bed (CFB) and Bubbling Fluidised Bed (BFB) boilers. The IGS engineering team have the benefit of a well-staffed and superbly equipped Technology Center. This large laboratory has advanced analytical tools and specific performance prediction capabilities that are used to develop and evaluate proprietary metal alloys and ceramic claddings, to provide reliable corrosion and erosion solutions for mission-critical equipment.

Biomass Corrosion Resistant Cladding

A recently developed material, IGS 5470, is a high velocity thermal spray (HVTS) applied metal alloy cladding shown to provide unprecedented corrosion resistance at the high temperatures found in Biomass boilers. This cladding is also designed to provide ease of on-site application. IGS CTO, Iain Hall, comments: “Merely specifying a corrosion resistant alloy does not ensure that the applied cladding system, with that alloy, will perform well in service. Very specific modifications are necessary to the material composition, process equipment and the application procedures, with additional post-treatment, to ensure that the as-sprayed cladding is resilient and capable of delivering an effective long-term corrosive and wear resistant barrier. Not all cladding systems are equal.”

IGS Global Presence

Having operational centers in strategic locations in North America, Europe, Asia and Africa, IGS provides its services worldwide. That said, each market is unique. Sören Stutin, General Manager at IGS Scandinavia, comments: “Scandinavia is a highly educated market in both CFB and renewable fuel thermal power and steam generation. Our boiler engineers have a deep understanding of metal wastage problems in boilers and years of experience in using thermal spray solutions. An important attribute is that even with this experience, Scandinavian engineers are open to innovation and once vetted, readily absorb the best available technology to improve operations. This combination of well-educated, curious, and savvy engineers is what makes our boiler industry so advanced.”

Large-Scale Application

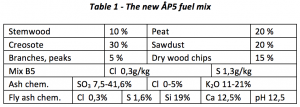

The IGS Europe s.r.o. Operations team performed a high velocity thermal spray (HVTS) application at Eon Värme Sverige AB Åbyverket, Örebro Sweden steam boiler 5 during the August to September 2017 maintenance period. ÅP5 is a 170 MW biomass-fired CFB boiler built in 1988 by Götaverken-Generator (currently Valmet Technologies Inc.) The steam conditions are 150 bar/540° C.

Åbyverket wanted to upgrade the existing surface protection system that was previously installed in preparation for a future change in fuel composition during the boiler revamp in 2017. In addition a height of 24 m of boiler tubing was changed on all 4 walls.

Biomass fuel is often multi-sourced. It may originate from virgin wood, plants or animal residue and may also contain recycled material like demolition wood. This uncertainty in the feed composition results in variations in the combustion process chemistry and gives rise to significant changes to the corrosion dynamics on water wall tube surfaces. In the case of fluidized bed boilers, this fuel mix together with changes in the bed material, adds an erosion/corrosion component to tube damage mechanisms.

Best Available Technology

While more aggressive fuels certainly increase tube material loss rates, this is not an entirely new problem. A number of other technologies have been employed to combat these problems. A subject matter expert for IGS in Waste to Energy and Biomass boilers, Cyril Narjoz says, “Some boiler operators believe that weld overlay is the only solution to protect boiler walls from biomass-induced corrosion safely. This was true some years ago, but now that IGS 5470 has proven its performance in several independent tests and practical applications. Being a faster, lower cost and more easily applied on-site technology, the IGS HVTS cladding with IGS 5470 is a great alternative for corrosion protection.”

IGS applied IGS 5470 to 993.5 m2 to the ÅP5 unit for erosion and corrosion protection in a 3-week period working 24 hours a day, 7 days a week, with eight spray units and technician rotation. The director of Operations for IGS Europe, Petr Sovadina, a boiler engineer with many years of thermal spray experience, commented, “We have an experienced and well-trained team, but it was our first large project in Scandinavia. The E.ON engineers were attentive and supportive, their close communication and collaboration with IGS mitigated many obstacles in the execution phase. As we understand that operators need to squeeze the critical path for boiler operations, IGS’s ability to mobilize 8 application teams enabled us to complete the application to the 993.5 m2 of water walls in 21 days. We are proud of our quality and glad to provide a warranty behind our work.”

Flawless Corrosion Protection

The first annual inspection of the IGS HVTS application was conducted in August 2018. The result was as expected; there was no degradation or thickness loss of the applied thermal spray cladding. The ceramic top coat system, IGS 6022, indicated the areas with the heaviest erosion. A cladding thickness mapping inspection was performed, as usual, and a full report provided to the customer,. The E.ON site manager Ingrid Bogren commented, “Our work is extremely important, that is why we choose the best services for our boilers. We closely monitor projects performed in our boilers, IGS has an experienced and quality-oriented team that listens to customer needs and delivers according to their promises.”

As the European energy market develops and uses more widely varying biomass fuels, facilities will face more difficult corrosion conditions than they have experienced before. IGS is well equipped to provide effective long-term surface protection barriers on existing tube water walls, stopping tube leaks and effectively eliminating the requirement for panel replacement by preserving the existing water wall tube condition.