Bubbling Fluidized Bed (BFB) Boilers

Life Extension of Furnace Tube in Biomass and Waste to Energy BFB Boilers

Biomass fired bubbling fluidized bed (BFB) boilers can suffer fireside corrosion-erosion of the furnace wall tubes, which restricts steam conditions and downgrades thermal efficiencies, also resulting in frequent maintenance of the water wall tubing. IGS metal coatings provide protection from the extremes of fireside corrosion wastage. IGS provides cost-effective in-situ HVTS® cladding having proven corrosion and erosion resistant qualities.

Corrosion-Erosion Mechanisms in WtE and Biomass BFB Boilers

Fireside corrosion-erosion is the main cause of metal loss on furnace wall tubing in biomass and waste fired BFB boilers. The rate of metal wastage is influenced by metal temperature (boiler pressure), gas temperature (heat flux). and combustion environment. The latter being a function of fuel chemistry and whether combustion is complete. Boiler furnace and final steam design temperatures are limited by the combusted fuel, as manufacturers adopt particular firing methods and temperature limits for given fuel chemistry. Designers have to decrease temperatures with an increase of chlorine, alkali and heavy metal contents present in the fuel.

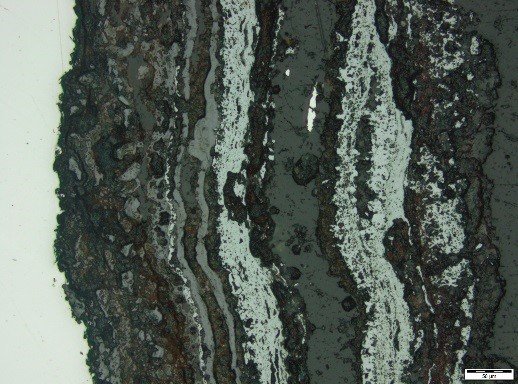

Chlorine readily reacts with volatile alkali metals to produce alkali metal chlorides, (Na+K)Cl, in the gaseous vapor phase. Alkali chlorides readily condense as ash deposits on gas tube metal surfaces, where it interacts with the normally protective oxide scales. The chloride-rich ash inhibits the growth of a dense, duplex oxide scale which would ordinarily act as a diffusion barrier to limit further corrosion. Frequently a chloride rich corrosion scale is observed between the oxide scale and the metal surface. Under the influence of heat flux, this leads to rapid diffusion of corrodents and corrosion products.

In addition to the alkali metals found in clean wood fuels, waste fuels frequently contain heavy metals such as lead and zinc. These metals react readily with chlorine and further contribute to the transport of chloride rich ash to the tube metal surface, increasing the corrosivity of the ash deposit and combustion environment.

Under these conditions, the dense corrosion scales are frequently disrupted, forming defective, multi-laminated scales with reduced mechanical properties. These scales are vulnerable to erosion damage and loss in a process termed corrosion-erosion, in which the corrosion scales are lost, leaving the underlying tube metal unprotected from further corrosion. Typically, higher gas velocity further increases the corrosion-erosion rate.

Erosion-Corrosion Resistant HVTS® Metalspray® Coatings

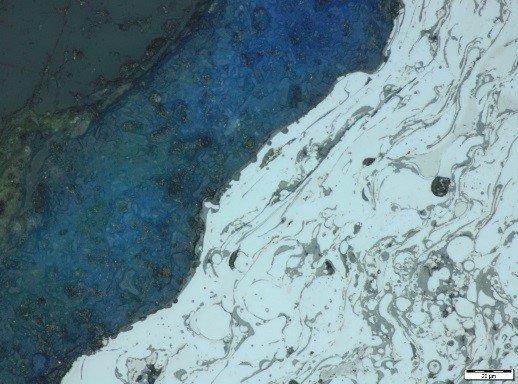

The use of IGS High Velocity Thermal Spray process ensures finely structured coating, with an order of magnitude lower permeability and greater homogeneity. Changes in feedstock chemistry have further improved performance by significantly reducing stress, increasing bond strength and mitigating oxide content. By addressing the root cause of these microstructural defects through the process and material chemistry, high velocity thermal spray cladding is successfully employed in the field, during shutdowns, with high production rates and low costs. As with welding and other coating technologies, surface preparation, material, process and procedure criteria should be well defined in coating specifications. Moreover, the IGS HVTS® does not generate Heat Affected Zone on the substrate or residual stresses on the base metal since the temperature of the base metal remains low even without water in the boiler tubes.

The thermally sprayed IGS coatings exhibit little if any observable corrosion damage or surface recession in the Biomass BFB applications. The IGS 5xxx coating exhibited a very minor increase in the oxidation on the outermost surface only. There is no discernible corrosion scale or penetration of combustion derived elements of the IGS HVTS® coating. In the field tests where unprotected tube sections suffer metal losses of hundreds of microns, IGS HVTS® coatings suffer approximately 1 – 3µm of material deterioration, meaning close to zero wastage rates.

CUI Mitigation Strategies

Preventing CUI can be achieved by many different corrosion management strategies. To prevent corrosion taking place the equipment designer or operator needs to ensure that the elements required for corrosion, commonly referred to as the Anode, Cathode, Metallic Pathway and Environment, are not allowed to develop. For Corrosion Under Insulation this can be done by controlling the environment (e.g. removing moisture), upgrading the substrate alloy etc. However, by far the most common method is utilizing a corrosion barrier or coating, to isolate the metal substrate from the environment and in addition to organic or non-metallic systems, the most common and widespread technology adopted is the application of Thermal Sprayed Aluminium.

Mitigating Corrosion/Erosion in WtE and Biomass Boilers

Erosion-Corrosion Resistant Cladding in the Market

The widespread solution to manage excessive fireside corrosion in the furnace section was to weld several millimeters of Inconel 625 cladding to the plain carbon steel tubing, either in the workshop prior to installation or on-site during a turnaround outage. Unfortunately. low erosion resistance of Inconel 625 leads to accelerated metal loss due to abrasion in many BFB waste-to-energy and biomass boilers.

The use of thermal spray coating is gaining great interest as an alternative to Inconel 625 weld cladding due to resistance to corrosion-erosion phenomena. Many attempts to employ traditional twin wire arc spray (TWAS) with alloy wire feedstock were unsuccessful. High levels of coating permeation by corrosive species in high-moisture content environments caused corrosion at the coating interface and frequently ended up with the coating delamination. Coating permeation may occur through chemical and structural weaknesses in an arc-sprayed coating. These are simple porosity, high oxide content, particle micro-cracking and/or through coating macro-cracking due to elevated stresses.

Our Services

Integrated Global Services provides on-site thermal spray coating inside WtE and Biomass BFB boilers in all countries of Europe, including the UK, Netherlands, Germany, Italy, Switzerland, and France, from our operations center in the Czech Republic. As an international company, we spray coatings in the United States, Middle East, Japan, South-East Asia, and Africa. We have a global infrastructure established so that we can bring solutions to our clients where and when they need them.

IGS HVTS® systems demonstrate extremely good corrosion and erosion resistance with little or no indications of metal loss in extreme conditions. Whereas Alloy 625 weld overlaid components must be replaced at end of life, IGS HVTS® can be reliably refurbished or even replaced in-situ without replacing the underlying component. The corrosion resistance coupled with the ease of application in-situ, makes the selection of such IGS coatings favorable in areas that traditionally have been protected using weld overlays.

I’m here to help

Colin Bateman

IGS Subject Matter Expert

Free consultation with an IGS Subject Matter Expert

IGS is here to provide information, answer questions and create an effective solution for your needs.